Method for preparing Ziegler Natta catalyst by taking porous polymer microsphere as carrier

A porous polymer and Ziegler-Natta technology, which is applied in the field of preparation of porous polymer microsphere-supported Ziegler-Natta catalysts, can solve the problem of not preparing porous polymer microsphere-supported Ziegler-Natta catalysts And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A preparation method of a porous polymer microsphere-supported Ziegler-Natta catalyst, comprising:

[0026] a) reacting porous polymer microspheres with alkyl magnesium chloride in a solvent to obtain a first reaction product;

[0027] b) combining the first reaction product with TiCl 4 obtaining a second reaction product in a solvent;

[0028] c) The second reaction product and the cocatalyst are formed into a porous polymer microsphere-supported Ziegler-Natta catalyst.

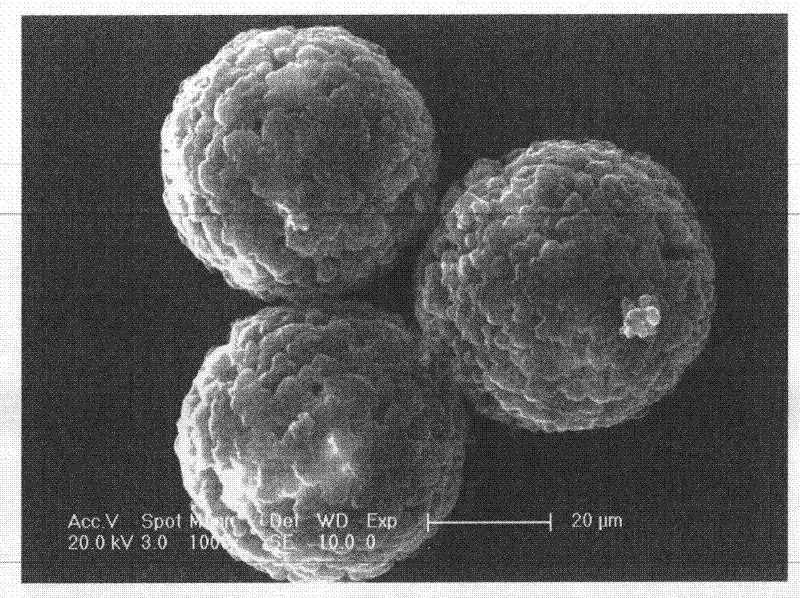

[0029] According to the present invention, the monomers of the porous polymer microspheres preferably include: styrene, divinylbenzene and acrylonitrile.

[0030] For the preparation method of most porous polymer microspheres, the present invention is not particularly limited, for example, it can be prepared according to the method of Chinese patent CN101434673A, and the specific steps include:

[0031] 1) Preparation of linear polystyrene seed microspheres

[0032] In a four-port reactor equipped...

Embodiment 1

[0052] Polystyrene seed microspheres were prepared by dispersion polymerization, and 10g styrene, 44g ethanol, 44g ethylene glycol monomethyl ether, 0.1g were added to a 250ml four-necked flask equipped with mechanical stirring, reflux condenser, nitrogen conduit, and thermometer. Azobisisobutyronitrile, 2g PVP K-30, set the stirring speed to 120rpm, insert the nitrogen conduit below the liquid level for 30min, then move the nitrogen conduit above the liquid level, turn on the cooling water, and heat the system to 70°C , the reaction was terminated after 24 hours of continuous stirring, the reaction solution was centrifuged to settle, the upper layer liquid was removed, the precipitate was washed several times with ethanol and water, and dried in a vacuum drying box for 24 hours to obtain polystyrene seed microparticles with a particle size of 1.5 μm. ball.

Embodiment 2

[0054] (1) 90 g of ethanol water of 0.25wt% sodium dodecyl sulfonate was prepared, and the mass ratio of ethanol and water in the ethanol water was 5:1.

[0055] (2) Take 25 g of the ethanol aqueous solution with a concentration of 0.25 wt% sodium dodecyl sulfonate prepared in step (1), add 0.5 g of polystyrene seed microspheres with a particle size of 1.5 μm prepared in Example 1, and ultrasonically Disperse for 10min.

[0056] (3) take 25g of the 0.25wt% sodium dodecyl sulfonate ethanol aqueous solution prepared in step (1), add 0.5g 1-chlorododecane co-swelling agent, ultrasonically disperse, and the ultrasonic time depends on the ultrasonic effect of emulsion droplets less than 0.5μm.

[0057] (4) mix the seed dispersed in step (2) and the dispersing auxiliary swelling agent in step (3), place in a 250ml four-necked flask equipped with mechanical stirring, reflux condenser, nitrogen conduit, and thermometer, at 30 ℃, 120rpm swelling for 12h, the swelling time is based on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com