Preparation method of a selective and specific recognition ppy@znfe2o4 magnetically imprinted composite photocatalyst

A photocatalyst, znfe2o4 technology, applied in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as poor catalytic activity, achieve good photocatalytic activity, The effect of good selectivity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

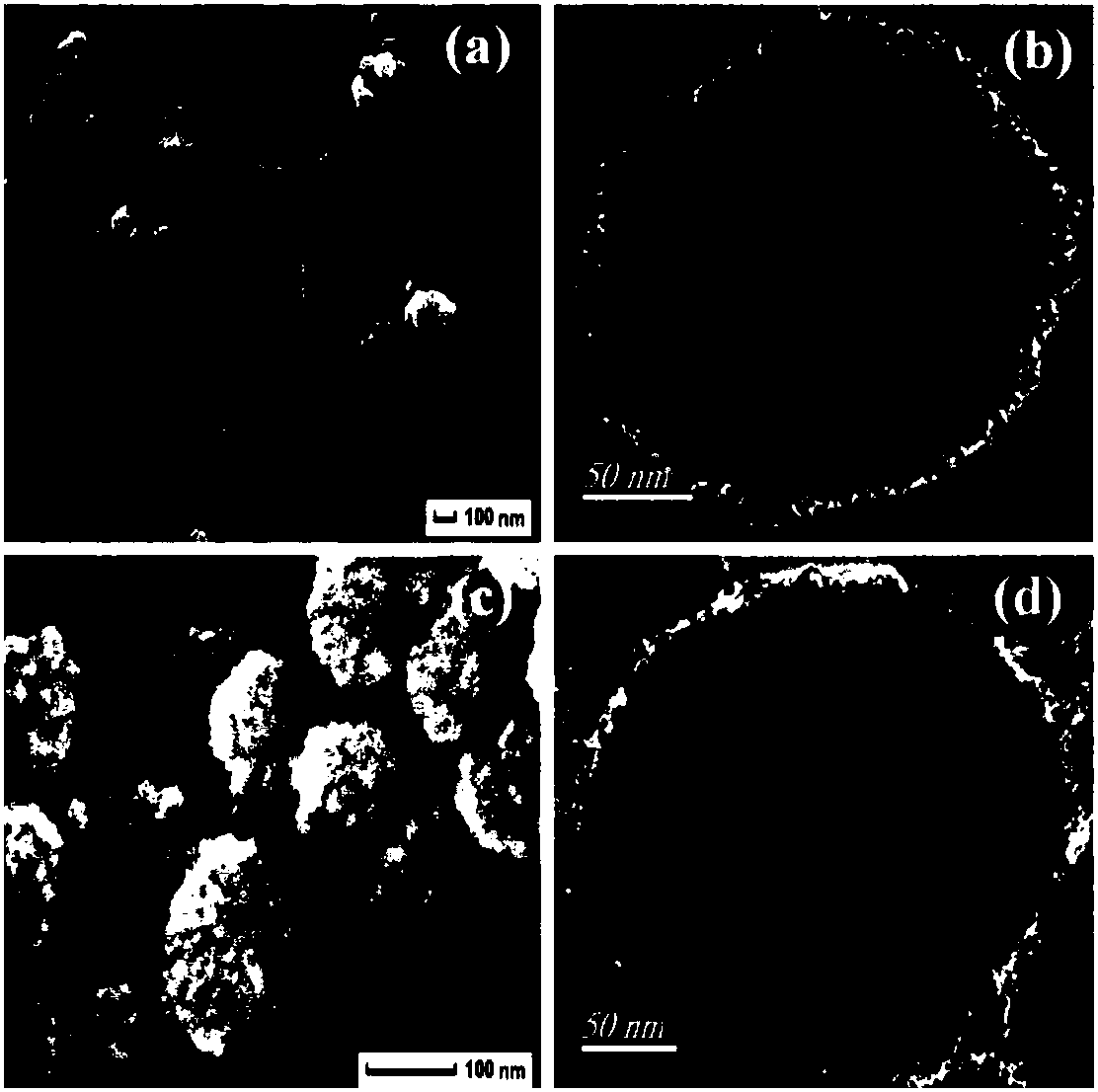

[0035] (1) ZnFe 2 o 4 Preparation of photocatalyst: First, add 0.808g of ferric nitrate nonahydrate and 0.297g of zinc nitrate hexahydrate into a mixed organic solvent containing 50mL of ethylene glycol and ethanol, stir magnetically until the mixture is uniform, then transfer to a stainless steel reaction kettle and heat to 200°C Reaction after 24h. After cooling to room temperature, separate with a magnet, wash with deionized water and ethanol three times each to remove excess reactants and side reactants, and vacuum dry at 50°C to obtain spherical ZnFe 2 o 4 Nanoparticles;

[0036] (2)PPy@ZnFe 2 o 4 Preparation of magnetically imprinted composite photocatalyst: 0.02 g of ciprofloxacin and 0.1 mL of pyrrole were added to 30 mL of dimethyl sulfoxide, dissolved by ultrasonic waves and stirred at room temperature to form a pre-assembly solution. With the ZnFe that makes in the 0.3g step (1) 2 o 4 Add the magnetic photocatalyst to the above pre-assembly solution, stir un...

Embodiment 2

[0040] Carry out by the same step of embodiment 1 preparation technology, difference is that in step (1) ZnFe 2 o 4 During semiconductor synthesis, the temperature of solvothermal synthesis is 150°C, 180°C, and 250°C to prepare different ZnFe 2 o 4 catalyst of light.

Embodiment 3

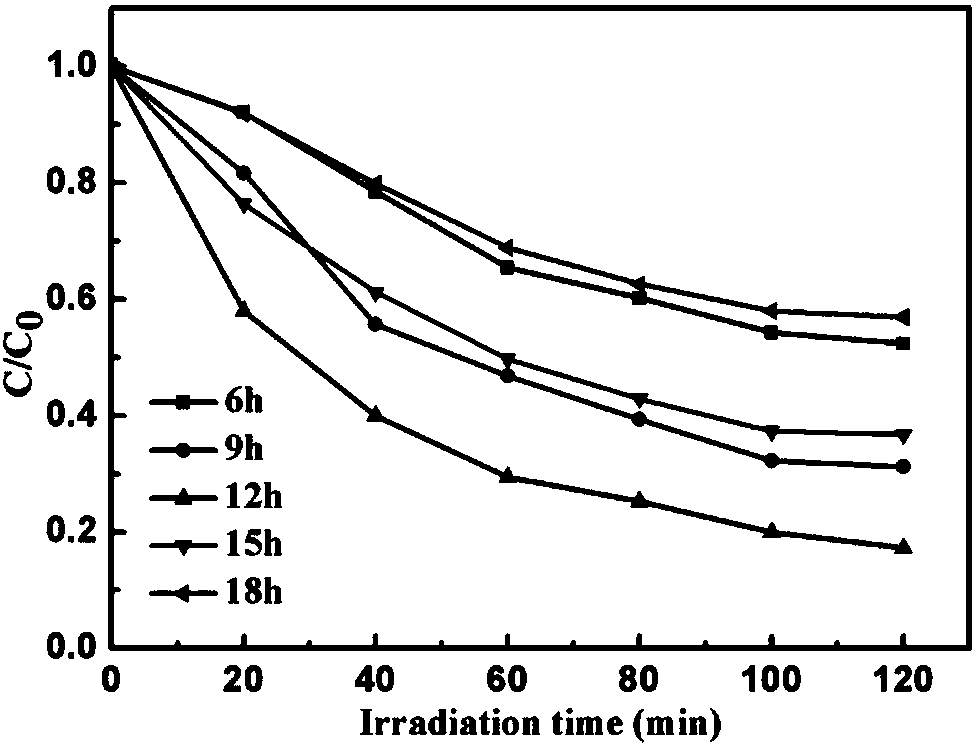

[0042] Carry out by the same step of embodiment 1 preparation technology, difference is that in step (1) ZnFe 2 o 4 During semiconductor synthesis, the time of solvothermal synthesis is 12h, 18h, 20h, 32h to prepare different ZnFe 2 o 4 catalyst of light.

[0043] By comparison of Example 2, Example 3 and Example 1, it was found that the ZnFe generated when the ambient temperature was 200°C for 24h 2 o 4 Semiconductor photocatalysts have relatively the best yield and catalytic activity. Therefore, this application selects the solvothermal reaction time as 24h, and the ambient temperature is 200°C to prepare ZnFe 2 o 4 Semiconductor photocatalyst, and preserved for PPy@ZnFe 2 o 4 Preparation of magnetically imprinted composite photocatalysts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com