Galvanized iron (vanadium) alloy process of acid system

An acid system and electro-galvanizing technology, which is applied in the acid system electro-galvanized iron alloy process, acid system electro-galvanized iron alloy additive, plating solution and process conditions, can solve the problem of large consumption of brightener, slow deposition speed, and low pH value of the plating solution. Stability and other issues, to achieve the effect of fast deposition speed, stable plating solution, and fine crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

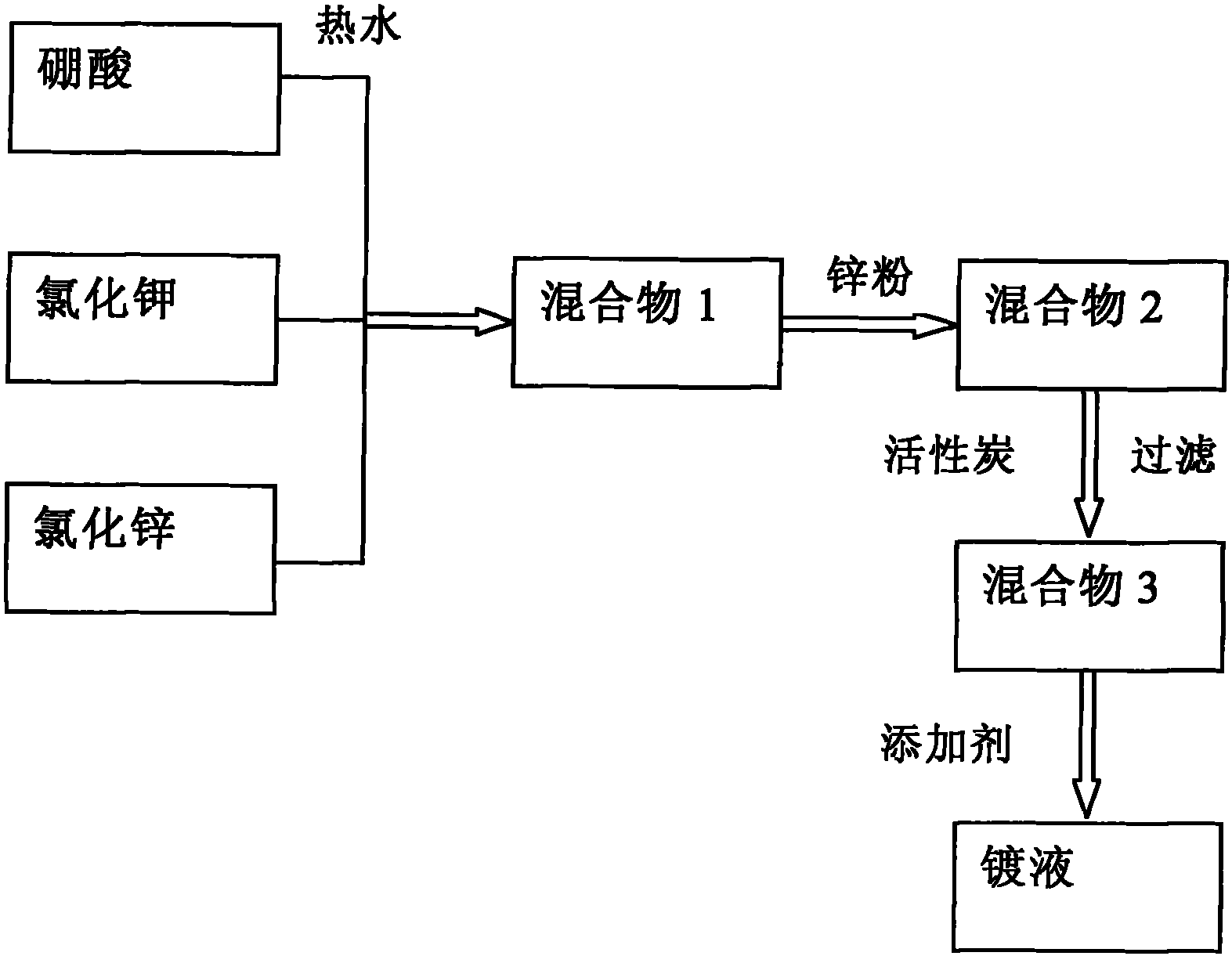

Method used

Image

Examples

Embodiment 1

[0051] The preparation of embodiment 1 main brightener

[0052] Prepare by any of the following methods.

[0053] Preparation method 1

[0054] A. Put 123-130g of pyridine 3-carboxylate into a three-necked flask, add 400-440g of water and stir;

[0055] B, adding mass fraction is 40% NaOH to adjust pH to 5.5~6.5;

[0056] C. Heat up to 80-105°C, drop 126-130 g of benzylidene chloride at a rate of 2-3 drops / minute; then heat to reflux temperature, and keep reflux for 3 hours;

[0057] D. Measure the pH value, if it is less than 6.5, adjust the pH value to 6.5-7.5 with 20% NaOH by mass fraction, stir for another half an hour until the pH is stable at 6.5, cool to room temperature and discharge to obtain the main brightener;

[0058] Preparation method 2:

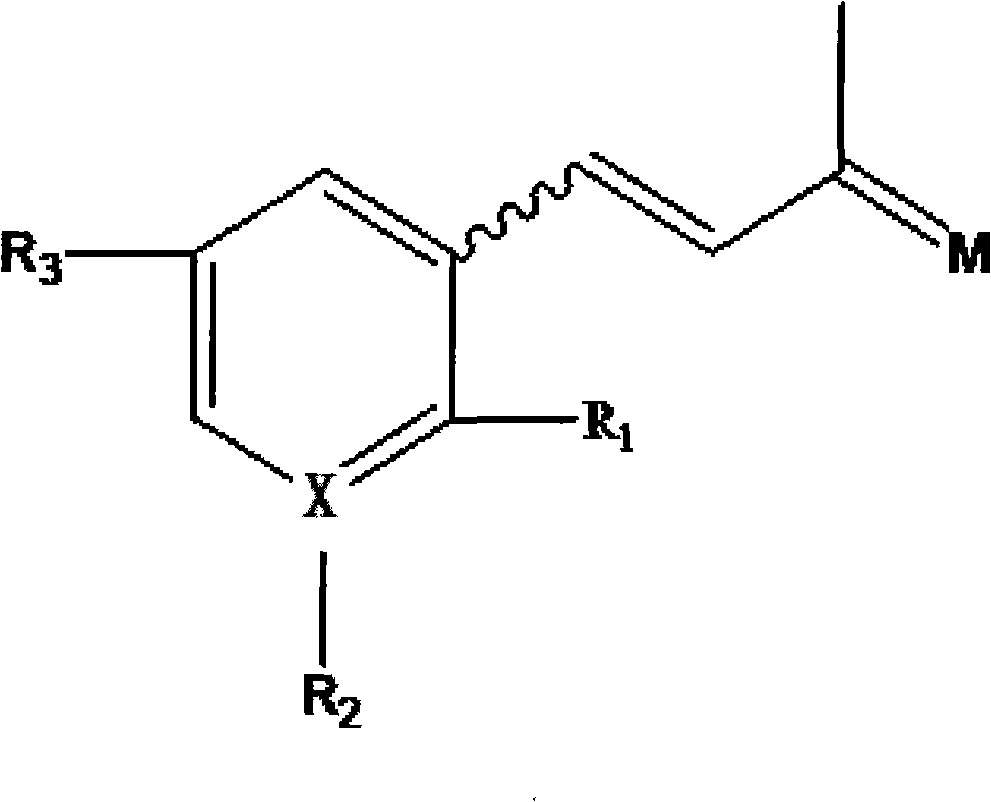

[0059] A. Add 71g of acetone into a three-necked flask equipped with a stirrer, a thermometer and a dropping funnel and a water bath, add a mixture of catalytic amount of potassium fluoride and alumina as a catalyst and 5-...

Embodiment 2

[0062] The preparation of embodiment 2 brighteners:

[0063] The main brightener dosage is: 10-25g / L;

[0064] The dosage of sodium benzoate: 50-150g / L; the dosage of niacin: 0.5-5g / L;

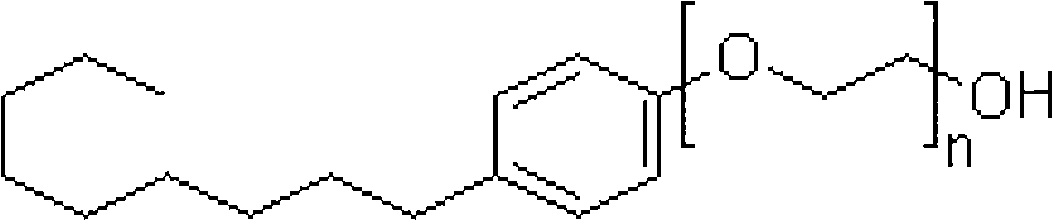

[0065] Carrier brightener dosage: 250-400g / L;

[0066] Water: balance.

[0067] First measure the main brightener and absolute ethanol prepared in Example 1, and prepare the absolute ethanol solution of the main brightener; mix sodium benzoate, nicotinic acid, carrier brightener and an appropriate amount of water, heat to dissolve, and then naturally cool . Then the cooled solution is uniformly mixed with the absolute ethanol solution of the main brightener, and finally the volume is adjusted to 100% with distilled water and deionized water.

Embodiment 3

[0068] The preparation of embodiment 3 complexing agent:

[0069] Sodium citrate dosage: 8-15g / L;

[0070] Ascorbic acid dosage: 1-5g / L;

[0071] Fe 2+ Content: 1.5-2.0g / L;

[0072] V 2+ Content: 0.01-0.02g / L;

[0073] Water: balance.

[0074] First weigh the specified amount of ferrous sulfate and vanadium pentoxide, dissolve the vanadium pentoxide in water, add ascorbic acid to reduce it to divalent. Then add ferrous sulfate, sodium citrate, and ascorbic acid respectively to dissolve them fully.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com