Electroplating solution without cyanogen for plating silver

A technology of cyanide-free silver plating and electroplating solution, applied in the field of electrochemical silver plating, can solve the problems of high cost of the plating solution, stability of the plating solution, pollution of the plating solution, etc., and achieves bright coating adhesion, good coating adhesion, The effect of good plating solution stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Dissolve the following compounds in deionized water to prepare cyanide-free silver plating solution

[0023] AgNO 3 17g / L

[0024] Uric acid 134g / L

[0025] KNO 3 20g / L

[0026] KOH 168g / L

[0027] Polyethyleneimine 1g / L

[0028] KSeCN 2mg / L

[0029] Preparation temperature 10℃~60℃

[0030] According to the electroplating step in the specific embodiment, the electroplating operation is performed using the cyanide-free silver plating solution.

Embodiment 2

[0032] Dissolve the following compounds in deionized water to prepare cyanide-free silver plating solution

[0033] AgNO 3 17g / L

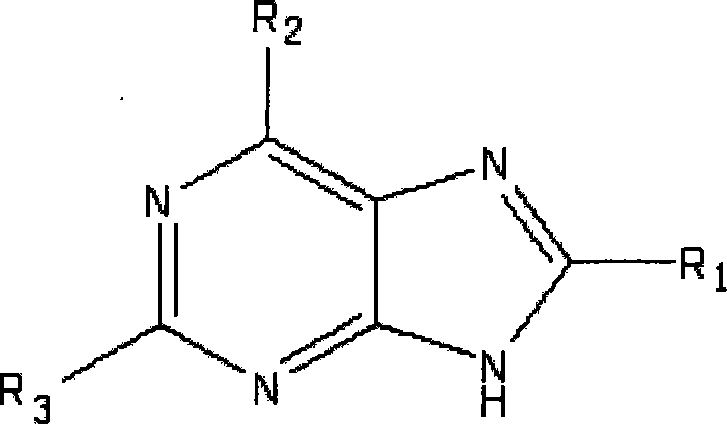

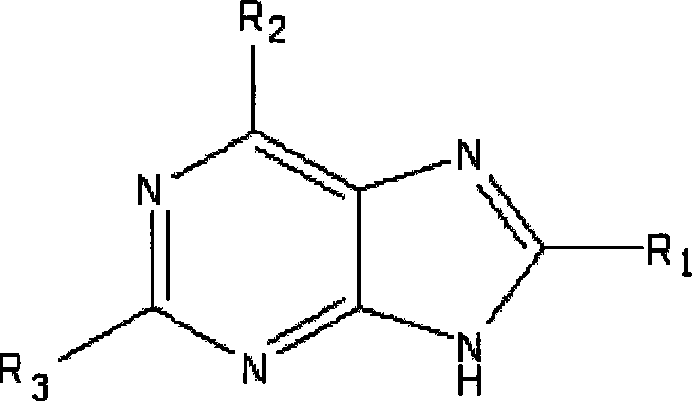

[0034] Guanine 129g / L

[0035] KNO 3 20g / L

[0036] KOH 139g / L

[0037] Polyethyleneimine 1.5g / L

[0038] KSeCN 2mg / L

[0039] Preparation temperature 10℃~60℃

[0040] According to the electroplating step in the specific embodiment, the electroplating operation is performed using the cyanide-free silver plating solution.

Embodiment 3

[0042] Dissolve the following compounds in deionized water to prepare cyanide-free silver plating solution

[0043] AgNO 3 17g / L

[0044] Adenine 108g / L

[0045] KNO 3 20g / L

[0046] KOH 153g / L

[0047] Polyethyleneimine 1g / L

[0048] KSCN 5mg / L

[0049] Preparation temperature 10℃~60℃

[0050] According to the electroplating step in the specific embodiment, the electroplating operation is performed using the cyanide-free silver plating solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com