Non-preplating type non-cyanide silver-plating electroplate liquid

A cyanide-free silver plating and electroplating solution technology, which is applied in the field of electrochemical silver plating, can solve the problems of stability of the plating solution, high cost of the plating solution, contamination of the plating solution, etc., and achieve good plating adhesion, bright plating adhesion, Good stability of plating solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] According to the preparation method of non-pre-plating type cyanide-free silver-plating solution of the present invention, the following compounds are prepared into cyanide-free silver-plating solution

[0020] AgNO 3 17g / L

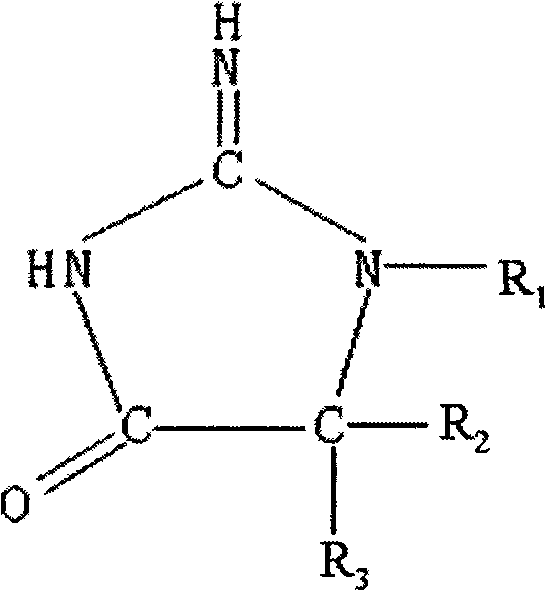

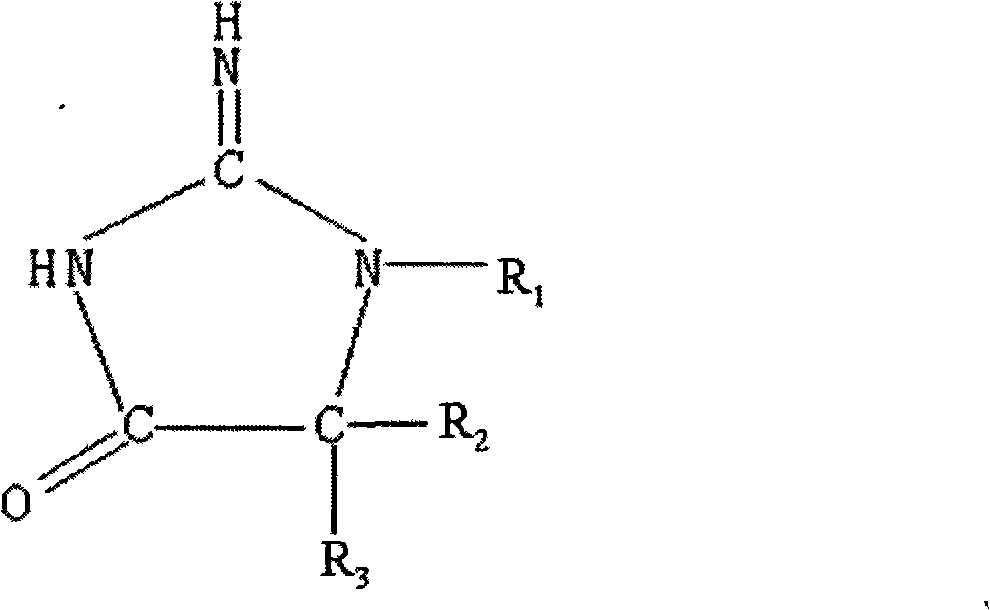

[0021] Creatinine 34g / L

[0022] KNO 3 50g / L

[0023] KOH 10g / L

[0024] Piperidine 1g / L

[0025] Temperature 10℃~80℃

[0026] According to the electroplating step in the specific embodiment, the electroplating operation is performed using the cyanide-free silver plating electroplating solution.

Embodiment 2

[0028] According to the preparation method of non-pre-plating type cyanide-free silver-plating solution of the present invention, the following compounds are prepared into cyanide-free silver-plating solution

[0029] AgNO 3 34g / L

[0030] Creatinine 60g / L

[0031] KNO 3 50g / L

[0032] KOH 15g / L

[0033] Glycine 1g / L

[0034] Temperature 10℃~80℃

[0035] According to the electroplating step in the specific embodiment, the electroplating operation is performed using the cyanide-free silver plating electroplating solution.

Embodiment 3

[0037] According to the preparation method of non-pre-plating type cyanide-free silver-plating solution of the present invention, the following compounds are prepared into cyanide-free silver-plating solution

[0038] AgNO 3 34g / L

[0039] Creatinine 90g / L

[0040] KNO 3 50g / L

[0041] KOH 25g / L

[0042] Cysteine 0.5g / L

[0043] Temperature 10℃~80℃

[0044] According to the electroplating step in the specific embodiment, the electroplating operation is performed using the cyanide-free silver plating electroplating solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com