Electroplating process for surface of magnesium alloy motorcycle hub

A technology of wheel hub surface and electroplating process, which is applied in the direction of metal material coating process, coating, solid diffusion coating, etc., to achieve the effects of high plating solution stability, long service life and excellent corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

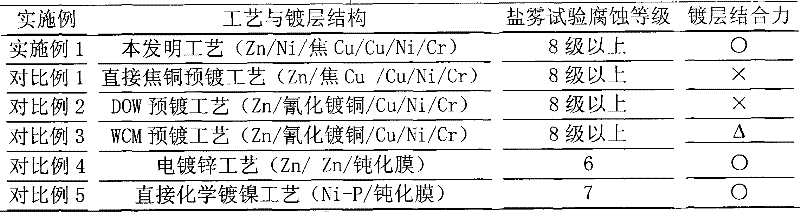

Examples

Embodiment 1

[0026] The test material is AM60 magnesium alloy motorcycle wheel. The process flow is: mechanical polishing→waxing→alkaline washing→acid washing→activation→dip zinc→nickel plating→coking copper plating→acid copper plating→semi-bright nickel plating→bright nickel plating →Chrome plating. (Wash with water once between each step)

[0027] (1) Polishing The surface of the magnesium alloy motorcycle wheel hub is treated to a bright surface by mechanical polishing.

[0028] (2) Composition and process operation of wax removal: Coconut oil diethanolamide phosphate: 18%-25% (mass percentage), coconut oil diethanolamide: 5%-12%, fatty alcohol polyoxyethylene ether: 1%-3%, nonylphenol polyoxyethylene ether: 1%-3%, nonylphenol polyoxyethylene ether phosphate: 1%-5%, water: 56%-63%; ultrasonic, temperature: 60- 70°C, 10min.

[0029] (3) Sodium carbonate (Na 2 CO 3 ): 15g·dm -3 , Sodium phosphate (Na 3 PO 4 ·12H 2 O): 10g·dm -3 , Sodium silicate (Na 2 SiO 3 ): 15g·dm -3 , OP emulsifier: 3g·dm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com