Electroless palladium plating bath and electroless palladium plating method

一种无电镀、不饱和的技术,应用在电路、电气元件、电固体器件等方向,达到高浴稳定性、优异软焊结合性能和引线接合性能、长浴寿命的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 8

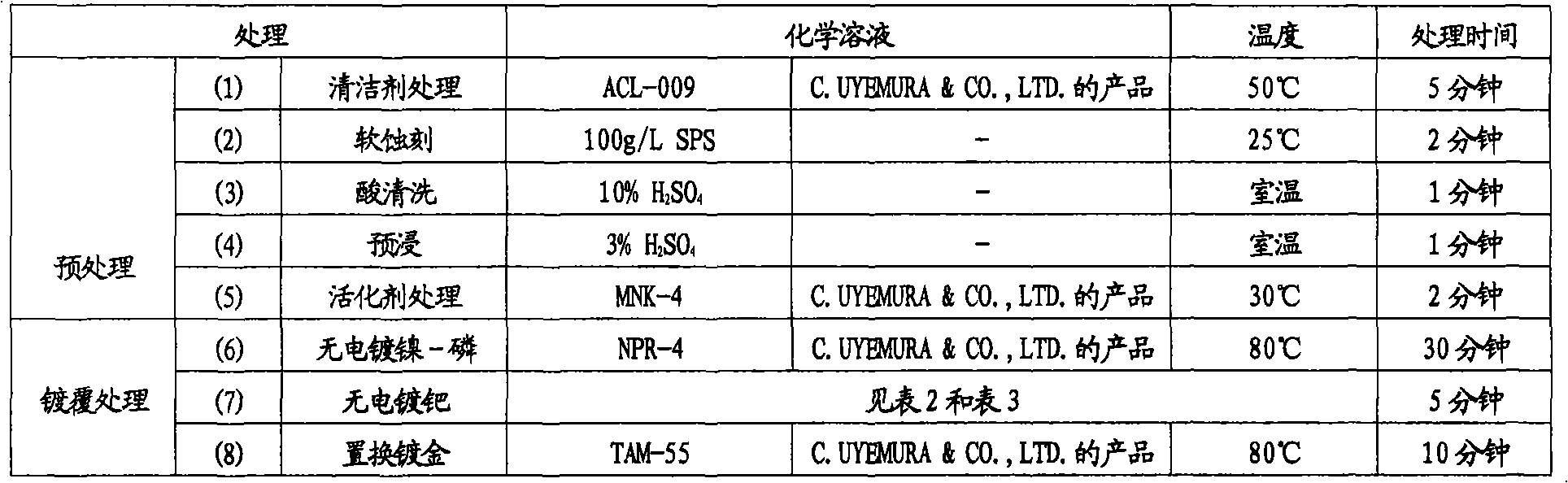

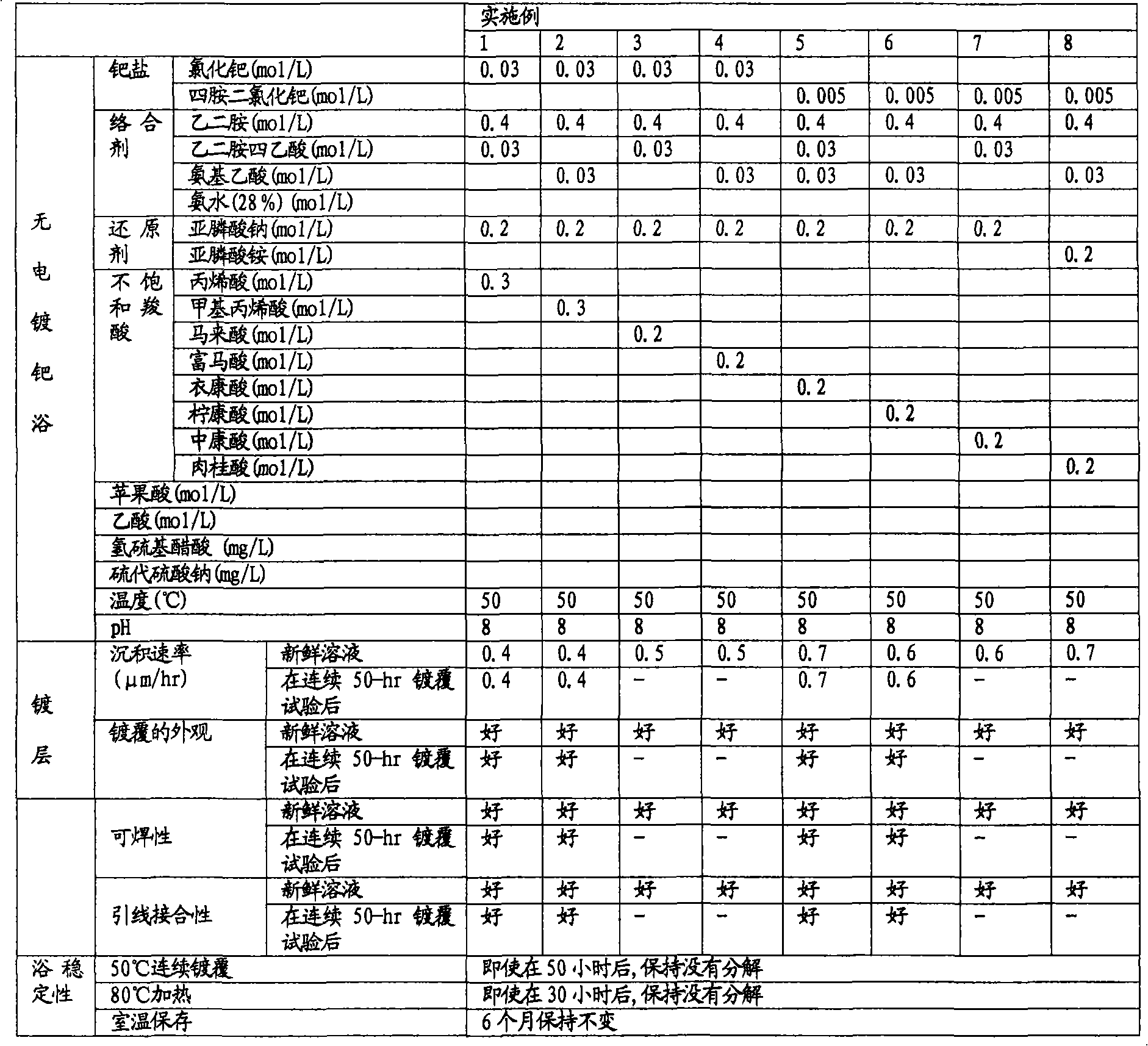

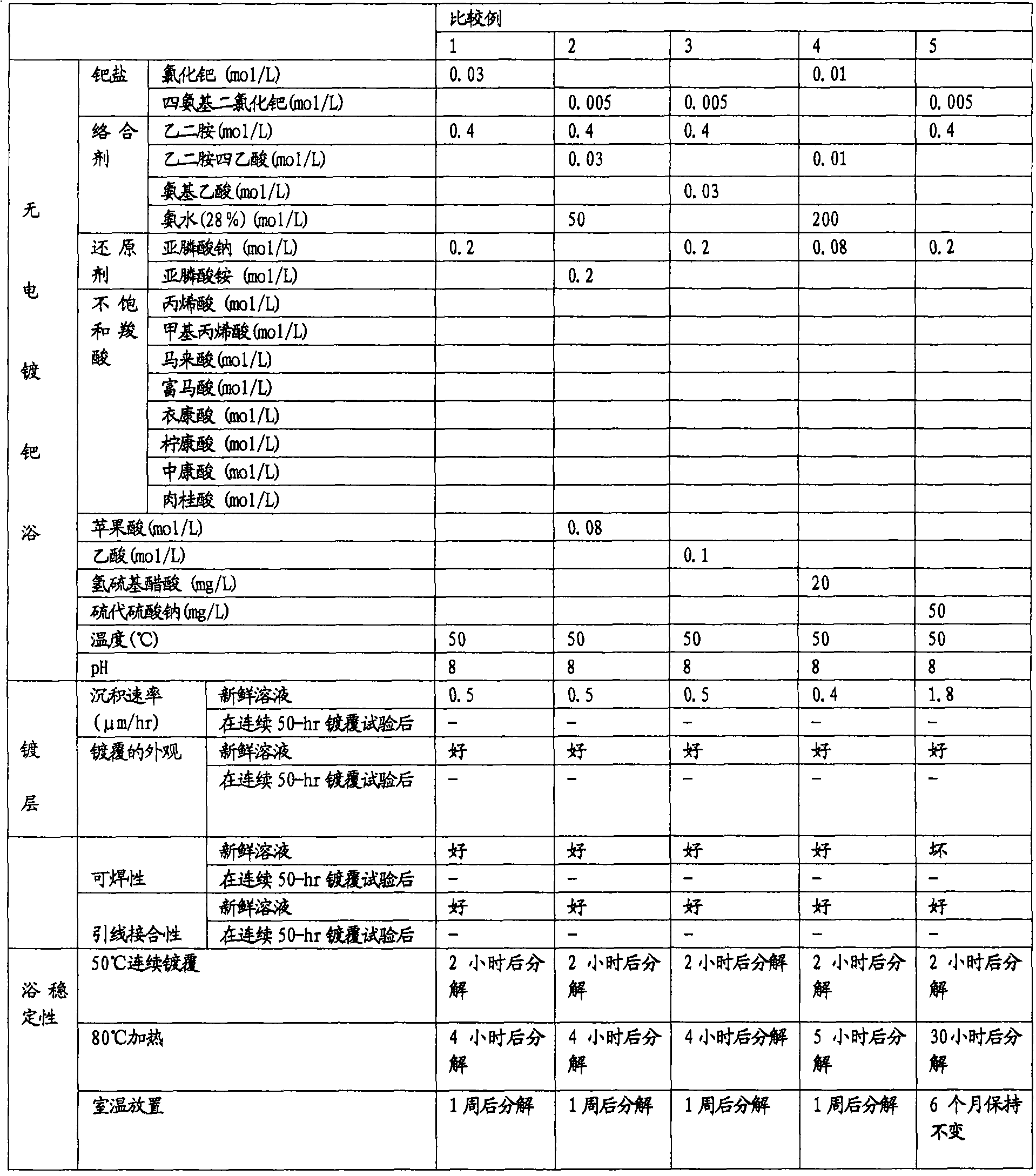

[0033] Examples 1 to 8, Comparative Examples 1 to 5

[0034]Electroless palladium plating baths of the compositions shown in Table 2 and Table 3 were prepared, and the plating properties of the plating baths, the properties of the resulting plated layers, and the stability of the plating baths were evaluated by the methods described below. In Examples 1, 2, 5 and 6, the properties of the coatings were also evaluated by using the coating bath after carrying out the continuous plating test at 50°C, which is described below. Results are shown in Tables 2 and 3.

[0035] Plating Appearance

[0036] Treatments (1) to (5) [pretreatment] and treatments (6) to (8) [plating treatment] shown in Table 1 were used for copper plates (size: 10 cm × 20 cm, thickness: 0.1 mm), And the appearance of the final coating was visually evaluated. When the plating layer had no unevenness in appearance, it was evaluated as "good", but when it had uneven appearance, it was evaluated as "bad".

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface pH | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com