Chemical nano-silver plating solution and preparation method thereof, and silver plating method for copper part

An electroless plating and nano-silver technology, applied in the field of electroless plating, can solve the problems of the stability of the electroless plating solution, the poor bonding force between the plating layer and the metal plating parts, etc., and achieve the effects of low price, simple and easy method, and wide source of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The copper sheet is composed of NaOH 10 g / L, Na 2 CO 3 55 g / L, Na 3 PO 4 55 g / L, Na 2 SiO 3 Slightly boil in 10 g / L lye for 10-15 minutes, wash with distilled water, dry and store in H at a temperature of 30-50 °C 2 SO 4 700 g / L, HCl 10 g / L, HNO 3 Immerse in 500 g / L etching solution for 15-30 s, take it out, rinse it with distilled water, fix it in the plating solution A configured according to Table 1, stir rapidly at a temperature of 25 °C, and slowly drip Add the plating solution B prepared according to the formula in Table 1, drop it for 5 minutes, stir and age for 15 minutes, wash with water after plating, and dry in the air.

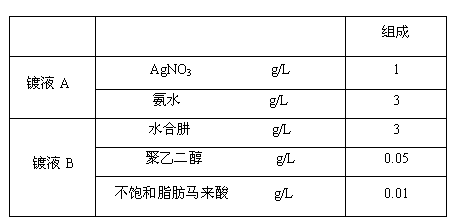

[0038] Table 1 chemical silver plating solution formula one

[0039]

[0040] The workpiece after electroless plating was measured at room temperature, and a uniform and fine silver coating was obtained. The silver particle size was 20-50 nm, and the thickness was about 1.6 μm. The surface was sterile through medical testing....

Embodiment 2

[0042] Same as Example 1, only at a temperature of 25 °C, the plating solution B was dropped in 5 minutes, and aged for 25 minutes with stirring. The workpiece after electroless plating was measured at room temperature, the size of the silver particles was 35 nm, and the thickness of the uniform and fine silver coating was about 2.5 μm, and the surface was sterile through medical testing.

Embodiment 3

[0044] Same as Example 1, only at a temperature of 25 °C, the plating solution B was dropped in 5 minutes, and aged for 60 minutes with stirring. The workpiece after electroless plating was measured at room temperature. The size of the silver particles was 25 nm, and the thickness of the uniform and fine silver coating was about 2.6 μm. The surface was sterile through medical testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com