Alkaline cyanide-free electro-deposition zinc-nickel alloy additive and application thereof

A zinc-nickel alloy and additive technology, which is applied in the field of electroplating zinc-nickel alloy, can solve the problems of low current efficiency, poor coating quality, and poor stability, and achieve high current efficiency, improved coating performance, and high stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0015] Embodiment 1: The alkaline cyanide-free electrodeposited zinc-nickel alloy additive in this embodiment is formulated from additives and ultrapure water. The additives are organic additives or a mixture of inorganic additives and organic additives. The components of the additive The concentration is 0.1 ~ 50 g / L.

[0016] Alkaline cyanide-free electrodeposition zinc-nickel alloy operation is as follows:

[0017] 1. Preparation of alkaline cyanide-free electrodeposition zinc-nickel alloy additive:

[0018] Sequentially weigh the corresponding amount of organic additives or a mixture of inorganic additives and organic additives, prepare a clear solution with ultrapure water, and store at a constant volume.

[0019] 2. Alkaline cyanide-free electrodeposition zinc-nickel alloy plating solution preparation:

[0020] (1) Use hydantoin derivatives as the main complexing agent, weigh the main complexing agent 20 ~ 400 g / L, zinc sulfate: 5 ~ 200 g / L and mix to obtain a clear so...

specific Embodiment approach 2

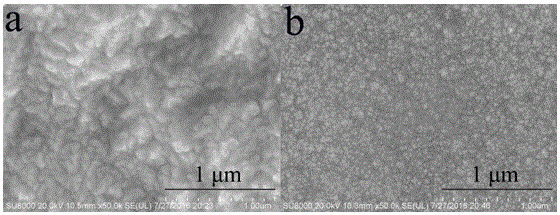

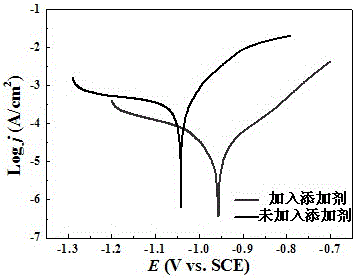

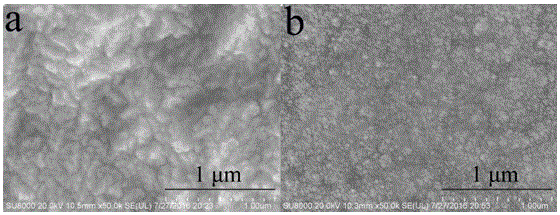

[0032]Specific embodiment two: the difference between this embodiment and specific embodiment one is that the components and concentrations of the electrodeposited zinc-nickel alloy additives are: adenine 10 g / L, guanine 5 g / L, cinnamon acetic acid 10 g / L g / L, antimony trichloride 0.5 g / L, potassium tellurite 5 g / L, and the additive dosage is 5 mL / L. The obtained coating has a bright, uniform and smooth appearance. SEM observation shows that the coating crystal is fine, dense, and free of pores and cracks. , The corrosion resistance test found that the corrosion resistance has been significantly improved.

specific Embodiment approach 3

[0033] Specific embodiment three: the difference between this embodiment and specific embodiments one and two is that the components and concentrations of the electrodeposited zinc-nickel alloy additives are: polyacrylamide 20 g / L, 3-methylquinoline 10 g / L, gum arabic 5 g / L, selenium dioxide 2 g / L, sodium dodecyl sulfonate 1 g / L, and the additive dosage was 10 mL / L. The crystals are fine, dense, free of pores and cracks, and the corrosion resistance test shows that the corrosion resistance has been significantly improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com