Reduced-form composite complexing non-cyanide chemical gold plating liquid and method

A cyanide chemical and reduction-based technology, which is applied in liquid chemical plating, metal material coating process, coating, etc., can solve the problems of limited cyanide-free chemical gold plating, difficult plating solution stability, and low service life of the plating solution. , to achieve the effect of wide application range, improved stability, dense and smooth coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

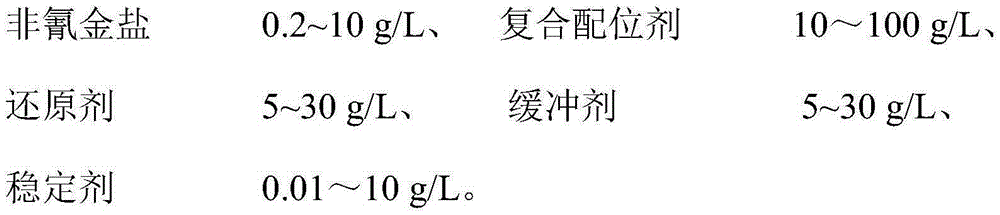

[0026] Plating solution composition:

[0027]

[0028] Pretreatment solution:

[0029]

[0030] Conditional control:

[0031] Pretreatment temperature 40°C, pH 8.5, time 2 minutes;

[0032] Plating temperature 65°C, pH 8.5, time 10 minutes;

[0033] Sample effect: dense coating, bright color.

Embodiment 2

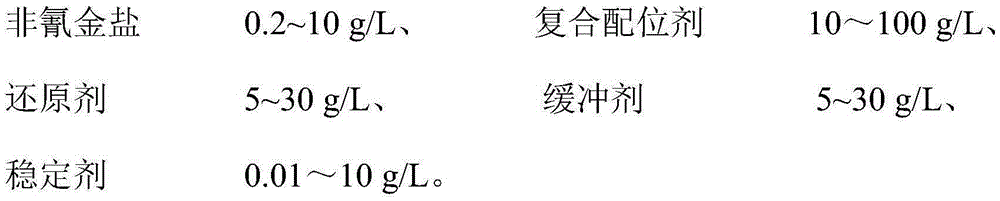

[0035] Plating solution composition:

[0036]

[0037] Pretreatment solution:

[0038]

[0039] Conditional control:

[0040] Pretreatment temperature 50°C, pH 7, time 1 minute;

[0041] The plating temperature is 70° C., pH 7, and the time is 10 minutes.

Embodiment 3

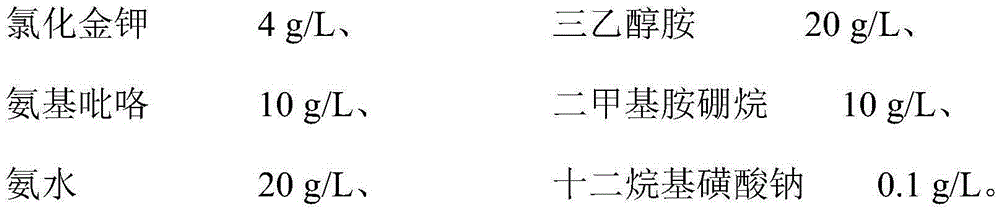

[0043] Plating solution composition:

[0044]

[0045] Pretreatment solution:

[0046]

[0047] Conditional control:

[0048] The pretreatment temperature is 30°C, pH 6.5, and the time is 3 minutes.

[0049] The plating temperature is 60°C, the pH is 6.5, and the time is 10 minutes.

[0050] Compared with the prior art, the present invention adopts the composite complexing agent, which can improve the stability of gold ions, and the coating is dense and smooth; it uses two steps to carry out the chemical gold plating method: 1. pretreatment of the substrate → 2. chemical gold plating, which can make The stability of the plating solution is higher, and it is suitable for the gold plating treatment of metal surfaces such as copper, nickel, cobalt, palladium, gold and their alloys. It has good process stability, long continuous production cycle, bright coating color, good corrosion resistance and weather resistance, etc. features.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com