Method for passivation of zinc and zinc alloy and chromium-free passivation solution

A chromium-free passivation and passivation solution technology, applied in the coating process of metal materials, etc., can solve the problems of ecological environmental hazards, poor corrosion resistance, high cost, etc., and achieve the effects of reducing costs, saving costs, and avoiding harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

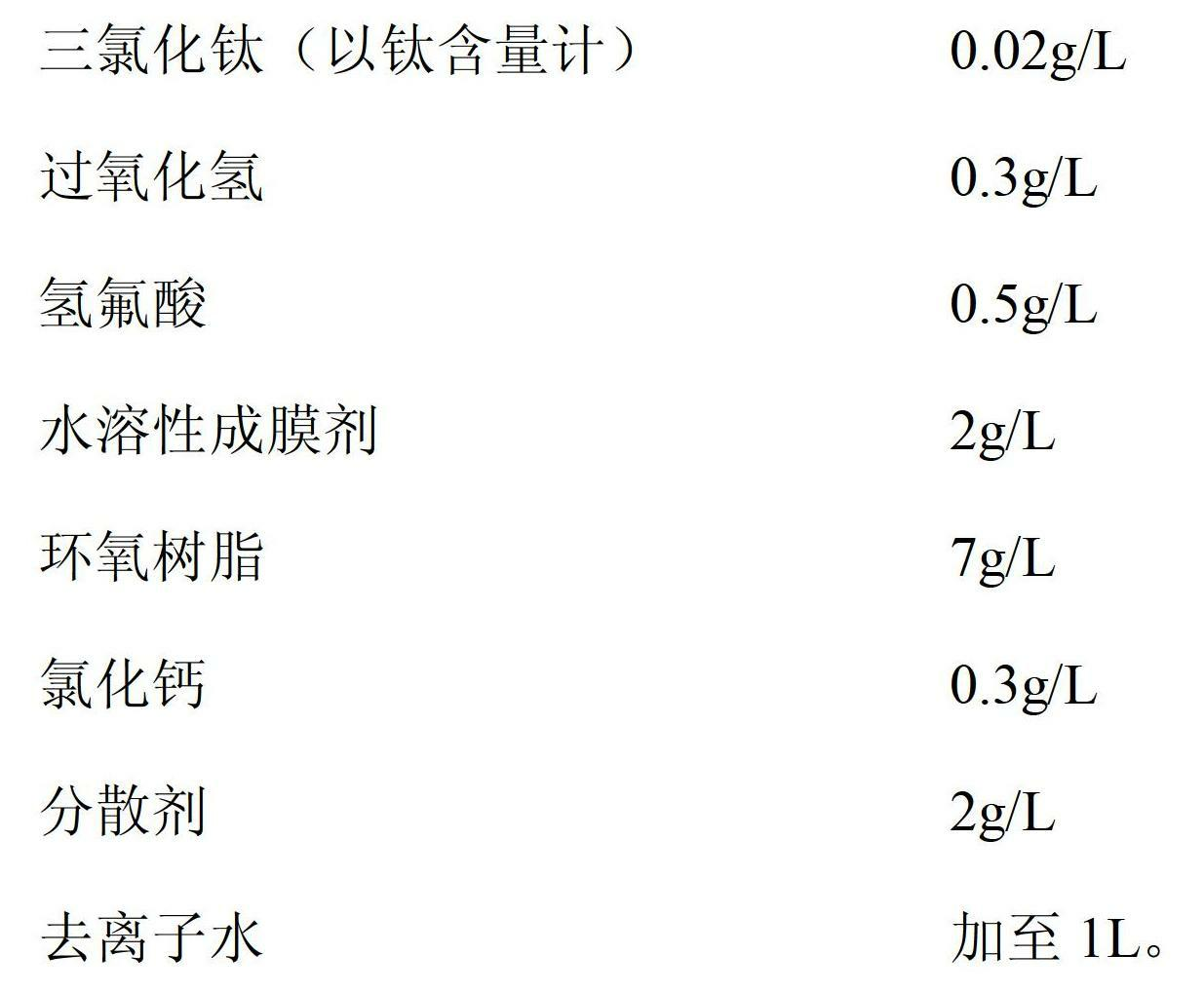

[0041] A solution consisting of the following was stirred and adjusted to pH 2 with 10% sodium hydroxide:

[0042]

[0043] Immerse the steel plate coated with 8 micron zinc in the above-mentioned chromium-free passivation solution for 5s, then let it stand in the air for 10s, then immerse it in the chromium-free passivation solution for 5s, then rinse and dry it; finally put the workpiece at 40℃ The passivation is completed after drying for 10 minutes, forming a uniform clear to blue conversion coating.

Embodiment 2

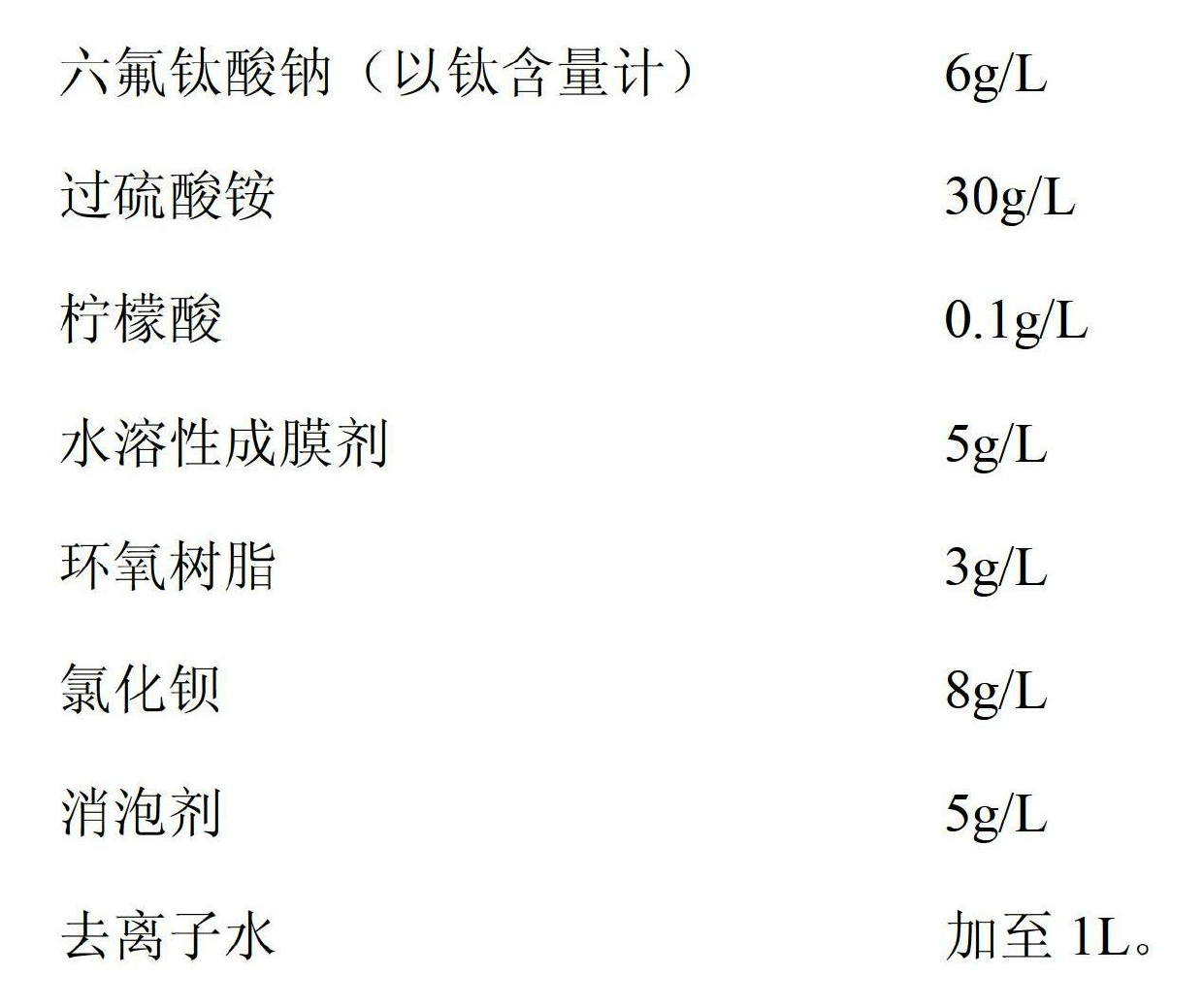

[0045] A solution consisting of the following was stirred and the pH was adjusted to 4.3 with 10% sodium hydroxide:

[0046]

[0047] Immerse the steel plate coated with 8 micron zinc in the above-mentioned chromium-free passivation solution for 5s, then let it stand in the air for 5s, then immerse it in the chromium-free passivation solution for 20s, then rinse and dry it; finally put the workpiece at 70℃ After drying for 15 minutes, the passivation is completed, and the resulting steel plate has a shiny pink / blue surface layer.

Embodiment 3

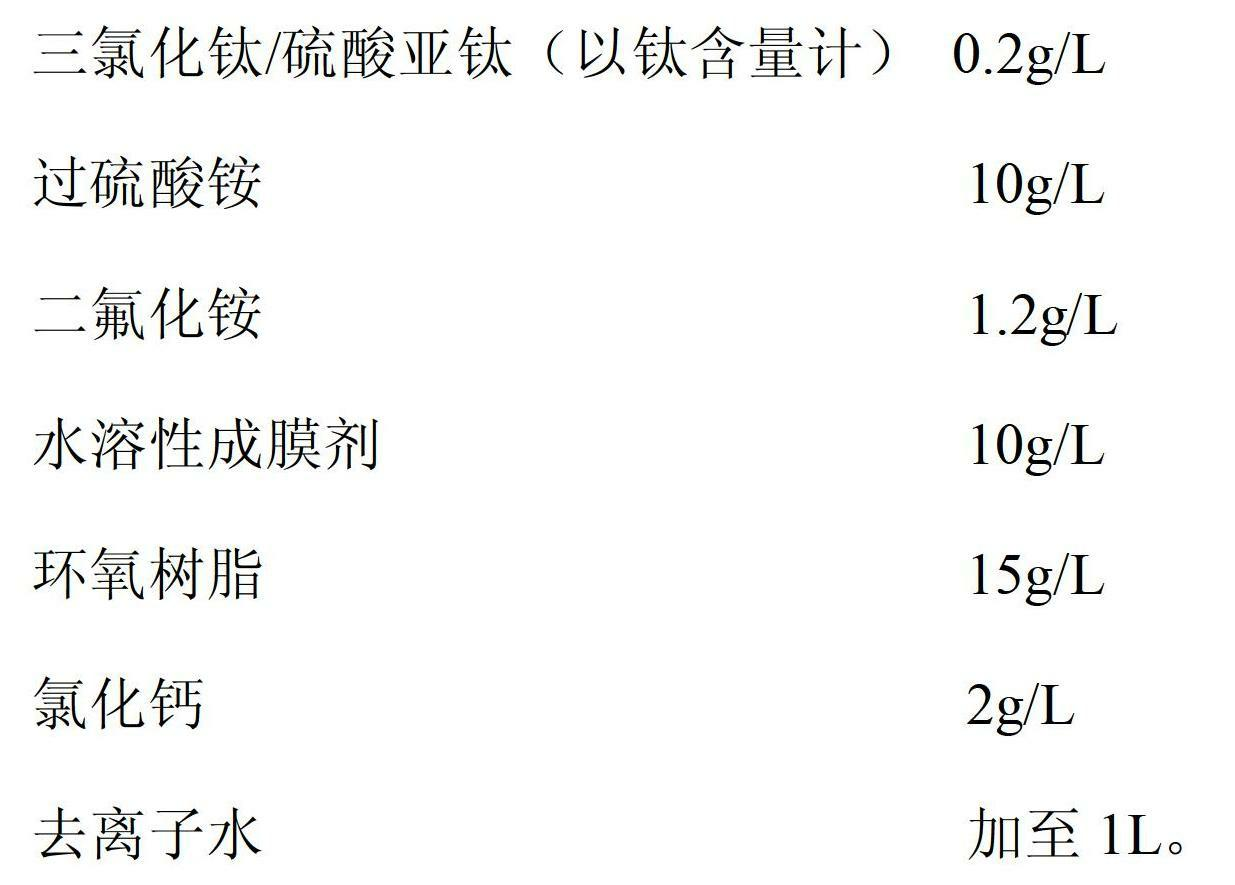

[0049] A solution consisting of the following was stirred and adjusted to pH 3 with 10% sodium hydroxide:

[0050]

[0051] Immerse the steel plate coated with 8 micron zinc in the above-mentioned chromium-free passivation solution for 20s, then let it stand in the air for 10s, then immerse it in the chromium-free passivation solution for 1min, then rinse and dry it; finally put the workpiece at 80℃ The passivation was completed after drying for 13 minutes, forming a uniform clear to blue conversion coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com