Neodymium-iron-boron magnet zinc plating and cathode electrophoresis composite protection process

A cathodic electrophoresis, NdFeB technology, applied in metal material coating process, superimposed layer plating, coating and other directions, can solve the problem of coating adhesion, corrosion resistance can not be guaranteed, sintered NdFeB magnets have poor corrosion resistance , technical performance can not meet the actual needs and other problems, to achieve the effect of long service life, improved corrosion resistance, and improved corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

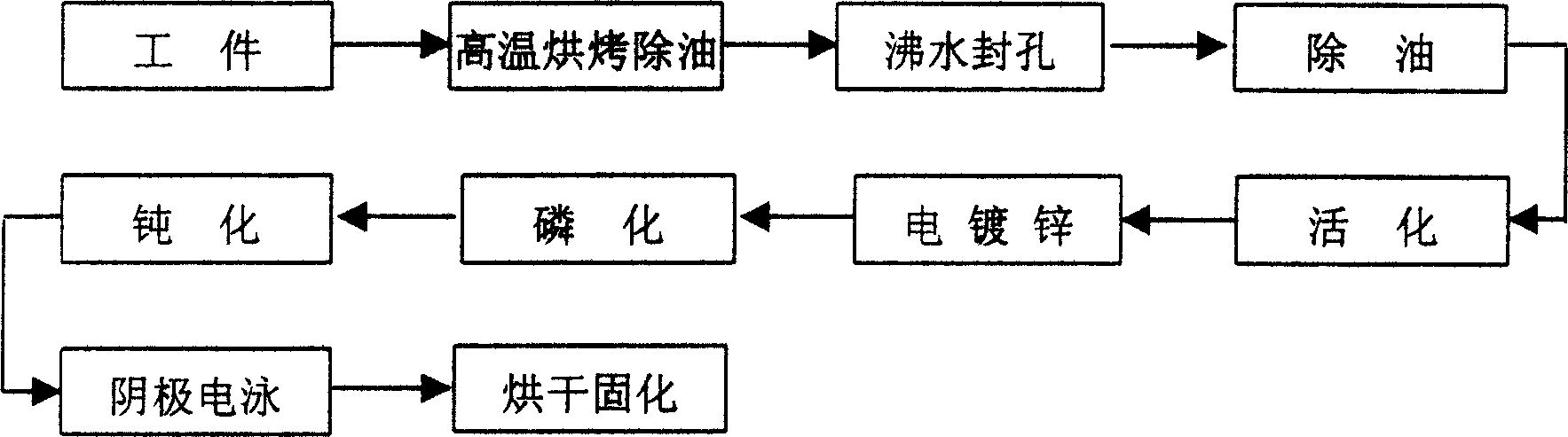

[0013] Such as figure 1 As shown, in conjunction with the embodiment, further illustrate the method for electro-galvanizing and cathodic electrophoresis composite protection of NdFeB magnets, the specific steps are as follows:

[0014] (1) High-temperature baking degreasing: bake the workpiece at 200°C for 1 hour to remove the oil on the surface of the workpiece and eliminate the magnetism of the material;

[0015] (2) Boiling water sealing: NdFeB matrix has a loose structure and many pores. In order to prevent the NdFeB matrix from infiltrating the pores during degreasing, rust removal, electroplating and cathodic electrophoresis, the acid and alkali and bath solution will be stored in the coating. There is a corrosive medium, and the bonding surface between the substrate and the coating is gradually corroded and pulverized during use, causing the coating to fall off, so the boiling water sealing treatment is selected. Put the workpiece into boiling water (distilled water or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com