Preparation for gold electrode with nano-pore structure by electrochemistry alloying/dealloying method

A nanoporous structure and electrochemical technology, applied in the direction of material electrochemical variables, electrodes, electrode shape/type, etc., can solve the problems of harsh process conditions and high cost, and achieve the effect of increasing specific surface area, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

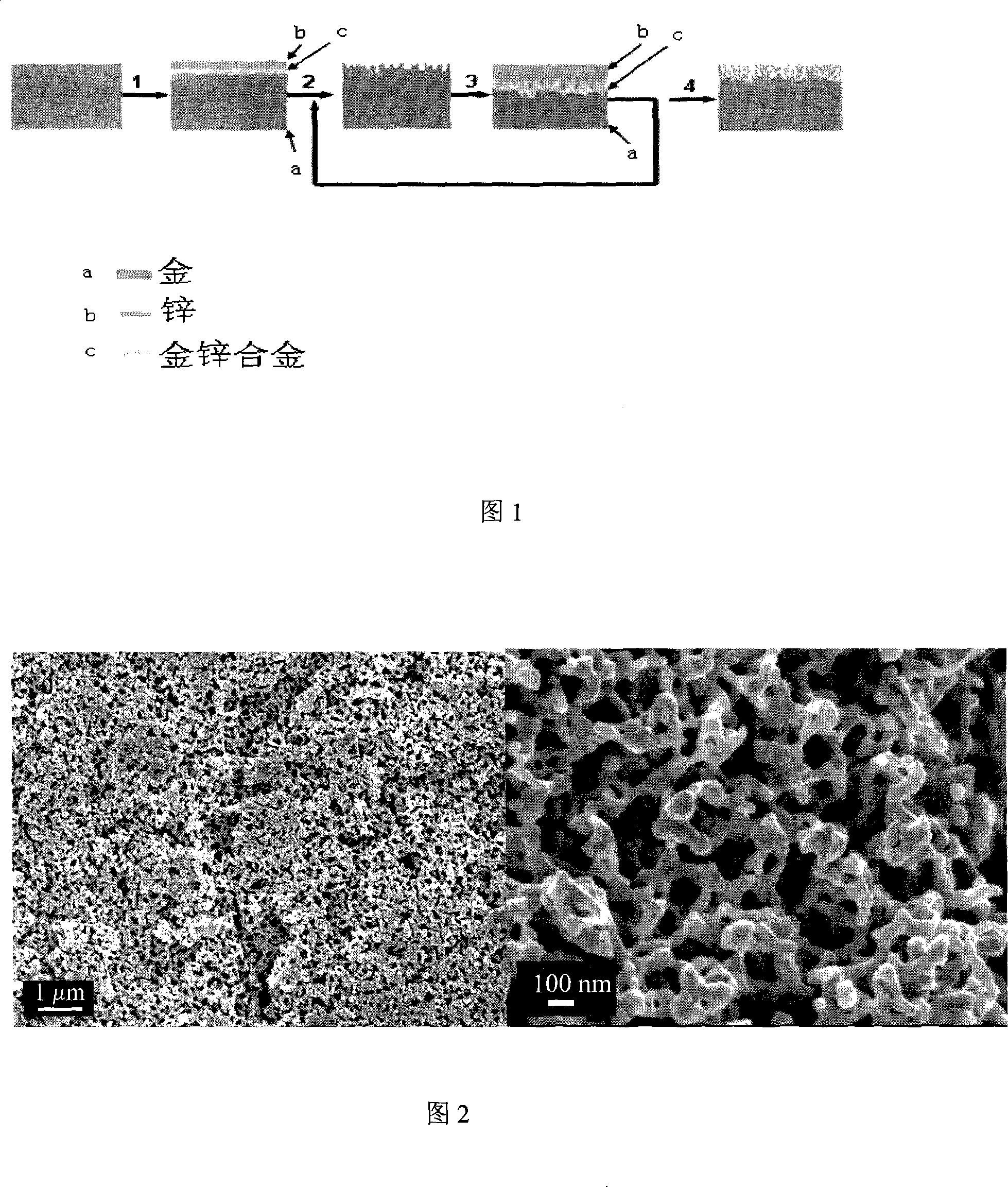

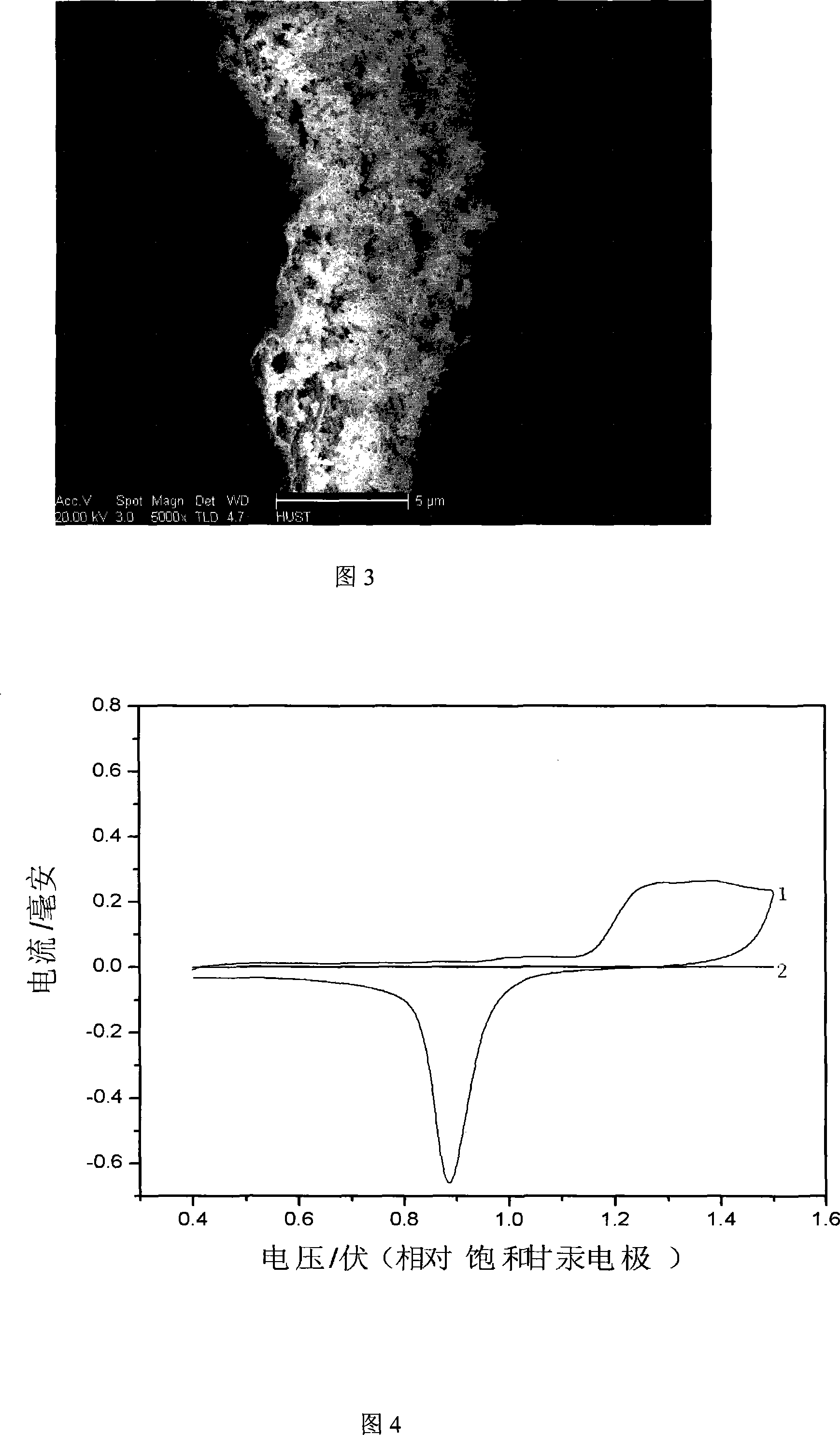

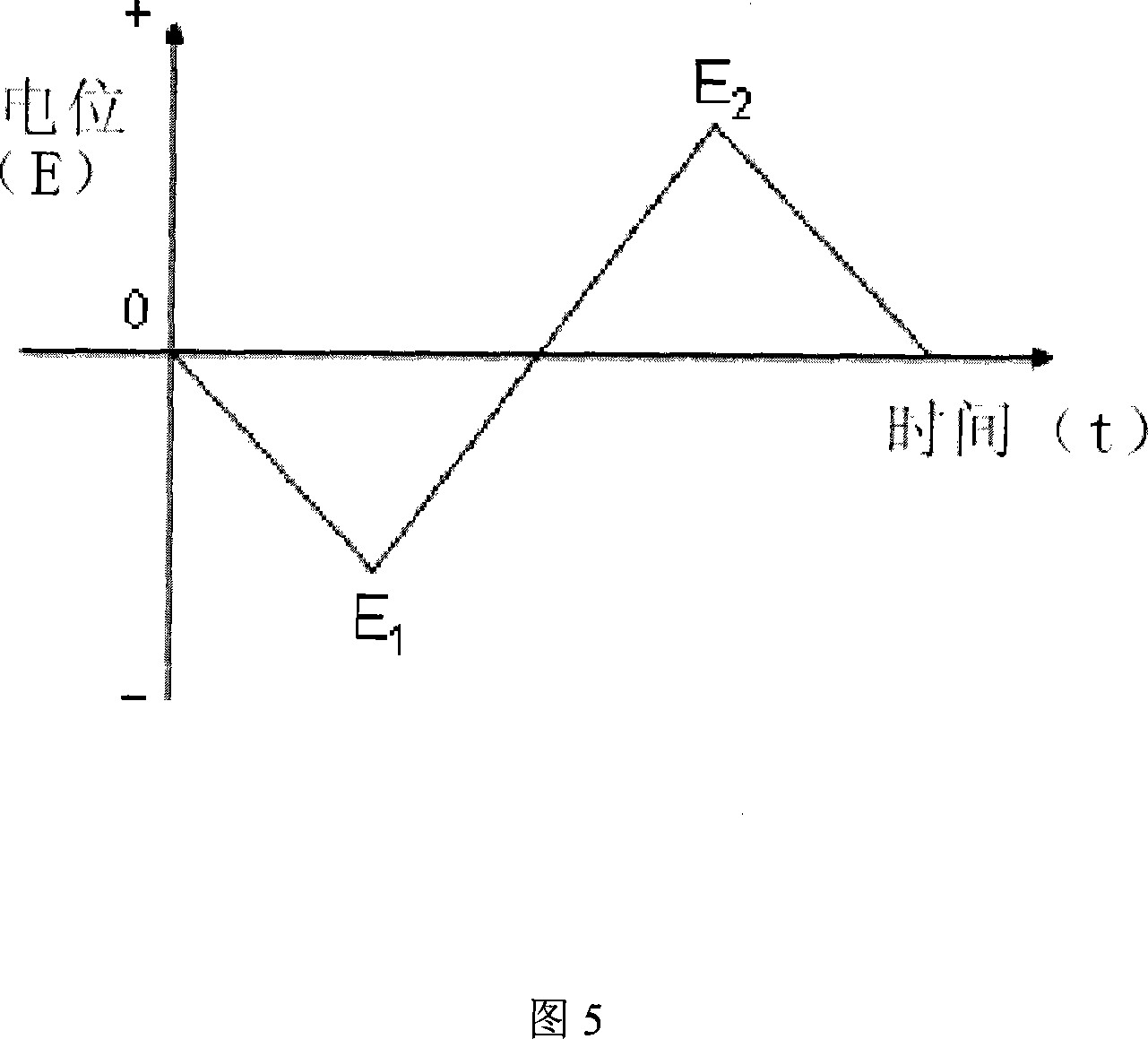

[0031] Electrochemical alloying / dealloying prepares a gold electrode with a nanoporous structure, and the preparation steps are:

[0032] Step 1, adding zinc chloride in 50 milliliters of benzyl alcohol, the content of configuration zinc ion is the benzyl alcohol solution of 2.0 mol / liter;

[0033] Step 2, insert a gold electrode into the solution configured in step 1 as the working electrode, the zinc sheet as the auxiliary electrode, and the platinum sheet as the reference electrode;

[0034] Step 3, utilize oil bath to heat the benzyl alcohol containing zinc chloride, its temperature is controlled at 80 ℃;

[0035] Step 4. Use the electrochemical workstation to apply a cyclic potential linear scan to the gold electrode, wherein a single potential linear scan is as follows: the cathode potential scan range is 0 volts→-0.5 volts→0 volts, and the scan speed range is 10 mV / s. The potential scanning range is 0 volts → 0.2 volts → 0 volts; repeat the above potential linear scann...

Embodiment 2

[0038] Electrochemical alloying / dealloying prepares a gold electrode with a nanoporous structure, and the preparation steps are:

[0039] Step 1, adding zinc sulfate in 50 milliliters of benzyl alcohol, the content of configuration zinc ion is the benzyl alcohol solution of 1.0 mol / liter;

[0040] Step 2, insert a gold electrode into the solution configured in step 1 as the working electrode, the zinc sheet as the auxiliary electrode, and the platinum sheet as the reference electrode;

[0041] Step 3, utilize oil bath to heat the benzyl alcohol containing zinc sulfate, and its temperature is controlled at 120 ℃;

[0042] Step 4. Use the electrochemical workstation to apply a cyclic potential linear scan to the gold electrode, wherein a single potential linear scan is as follows: the cathode potential scan range is 0 volts→-2.0 volts→0 volts, the scan speed range is 500 mV / s, and the anode potential scan range is 500 mV / s. The potential scanning range is 0 volts → 1.5 volts → ...

Embodiment 3

[0045] Electrochemical alloying / dealloying prepares a gold electrode with a nanoporous structure, and the preparation steps are:

[0046] Step 1, in 50 milliliters of N, N-dimethylformamide, add zinc chloride, the content of configuration zinc ion is the benzyl alcohol solution of 4.0 mol / liter;

[0047] Step 2, insert a gold electrode into the solution configured in step 1 as the working electrode, the zinc sheet as the auxiliary electrode, and the gold wire as the reference electrode;

[0048] Step 3, utilize oil bath to heat the benzyl alcohol containing zinc chloride, its temperature is controlled at 100 ℃;

[0049] Step 4, use the electrochemical workstation to apply a cyclic potential linear scan to the gold electrode, wherein a single potential linear scan is: the cathode potential scan range is 0 volts→-1.2 volts→0 volts, the scan speed range is 500 mV / s, and the anode potential scan range is 0 volts→-1.2 volts→0 volts. The potential scanning range is 0 volts → 0.6 vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com