Method for preparing chromium-free passivation solution, and method for passivating electrogalvanizing or zinc alloy layer by using same

A chromium-free passivation and electro-galvanizing technology, which is applied in the coating process of metal materials, etc., can solve the problems of short time, hexavalent chromium pollution of chromate passivation solution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

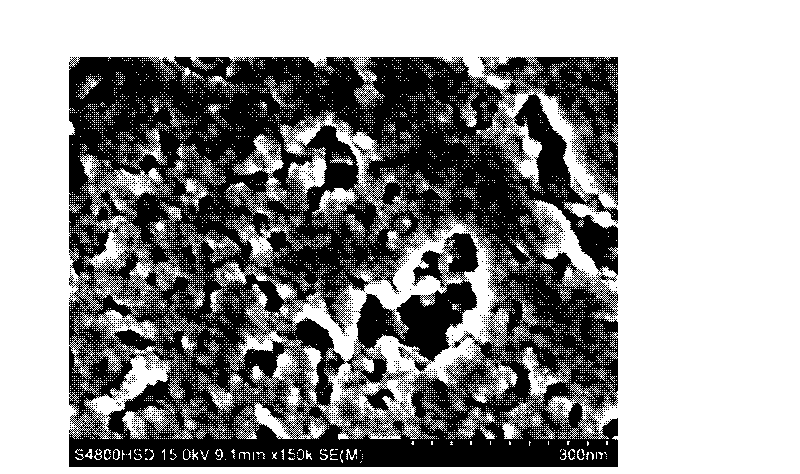

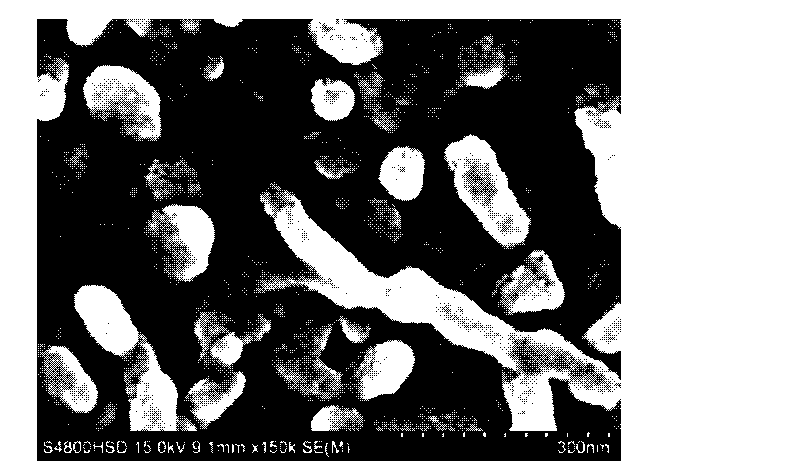

Image

Examples

specific Embodiment approach 1

[0011] Specific embodiment one: the preparation method of chromium-free passivation solution in the present embodiment is as follows: one, the preparation of A concentrated solution: titanium salt, complexing agent, strong acid and oxidizing agent are dissolved in deionized water, obtain A concentrated solution, wherein The ratio of titanium salt to deionized water is 0.001-0.15g: 1mL, the ratio of complexing agent to deionized water is 0.005-0.3g: 1mL, the ratio of strong acid to deionized water is 0.001-0.05mL: 1mL, the ratio of oxidizing agent to The ratio of deionized water is 0.005 ~ 0.4g: 1mL; 2. Preparation of B concentrate: dissolve silicate, molybdate and phosphorus-containing substances in deionized water to obtain B concentrate, wherein silicate and deionized The ratio of ionized water is 0.005~0.25g: 1mL, the ratio of molybdate to deionized water is 0.005~0.25g: 1mL, the ratio of phosphorus-containing substances to deionized water is 0.005~0.1g: 1mL; The concentrat...

specific Embodiment approach 2

[0013] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the titanium salt in step 1 is one of titanium trichloride and titanium sulfate or a mixture of both. Others are the same as in the first embodiment.

[0014] In this embodiment, when the titanium salt is a mixture of titanium trichloride and titanous sulfate, the ratio of titanium trichloride and titanous sulfate is arbitrary.

[0015] The stable time of the concentrated solution A and the concentrated solution B prepared in this embodiment is 45-60 days when stored separately, and the stable time of the chromium-free passivation solution prepared after mixing the concentrated solution A and B is 8-10 days. The A concentrated solution and the B concentrated solution in this embodiment are stored separately, and the A concentrated solution and the B concentrated solution are mixed before the passivation electroplated zinc or zinc alloy layer, and then prepared into a chromium-free passivation ...

specific Embodiment approach 3

[0016] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the complexing agent described in step one is ethylenediaminetetraacetic acid, malic acid, glycine, sodium dihydrogen phosphate, α-hydroxyphenylacetic acid, fluorine One or a combination of sodium chloride and N-benzyloxycarbonyl amino acids. Others are the same as in the first or second embodiment.

[0017] In this embodiment, when the complexing agent is a composition, the ratio of each component is arbitrary.

[0018] The stable time of the concentrated solution A and the concentrated solution B prepared in this embodiment is 45-60 days when stored separately, and the stable time of the chromium-free passivation solution prepared after mixing the concentrated solution A and B is 8-10 days. The A concentrated solution and the B concentrated solution in this embodiment are stored separately, and the A concentrated solution and the B concentrated solution are mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com