High-capacity rapid charge graphite negative electrode material and preparation method thereof

A graphite negative electrode, high-capacity technology, applied to battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of no optimal combination of raw materials, poor fast charging performance, and inability to meet high-rate fast charging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

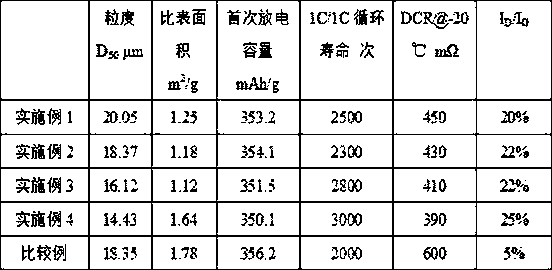

Embodiment 1

[0037]The needle coke and the non-graphitizable petroleum coke were pulverized, spheroidized, classified, and then mixed in a mass percentage of 95:5 to obtain carbon powder with an average particle size of 12 μm. The obtained carbon micropowder was mixed with petroleum pitch (residual carbon value 10%, softening point 40°C, β resin content 5%), and the pitch mixing ratio was 1% by mass percentage to obtain a mixed precursor. The mixed precursor was compounded in the reactor, the stirring speed was 100rpm, the heating temperature was 400°C, and the heating time was 2h to obtain the composite precursor, and the volatile content of the composite precursor was 8%. Put the composite precursor into a roller-type mechanical mill for crushing, and remove extremely large particles at the same time to obtain a crushed precursor with an average particle size of 18 μm. The crushed precursor is subjected to high-temperature graphitization, the heating temperature is 3000°C, the heating ti...

Embodiment 2

[0039] The natural graphite and the non-graphitizable pitch coke were pulverized, spheroidized, classified, and then mixed with a mixing ratio of 90:10 by mass percentage to obtain carbon powder with an average particle size of 10 μm. The obtained carbon micropowder was mixed with petroleum pitch (residual carbon value 70%, softening point 350 °C, β resin content 50%), and the mixing ratio of pitch was 10% by mass percentage to obtain a mixed precursor. The mixed precursor was compounded in the reactor, the stirring speed was 50rpm, the heating temperature was 500°C, and the heating time was 4h to obtain a composite precursor with a volatile content of 6%. Put the composite precursor into a roller-type mechanical mill for crushing, and remove extremely large particles at the same time to obtain a crushed precursor with an average particle size of 16 μm. The crushed precursor is subjected to high-temperature graphitization, the heating temperature is 3100°C, the heating time is...

Embodiment 3

[0041] The easy-to-graphitize petroleum coke and the hard-to-graphitize pitch coke were pulverized, spheroidized, classified, and then mixed in a mass percentage of 80:20 to obtain carbon micropowder with an average particle size of 3 μm. The obtained carbon micropowder was mixed with petroleum pitch (residual carbon value 30%, softening point 150 °C, β resin content 10%), and the mixing ratio of pitch was 40% by mass percentage to obtain a mixed precursor. The mixed precursor was compounded in the reactor, the stirring speed was 5rpm, the heating temperature was 200°C, and the heating time was 6h to obtain a composite precursor with a volatile content of 4%. Put the composite precursor into a roller-type mechanical mill for crushing, and remove extremely large particles at the same time to obtain a crushed precursor with an average particle size of 5 μm. The crushed precursor is subjected to high-temperature graphitization, the heating temperature is 2800°C, the heating time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com