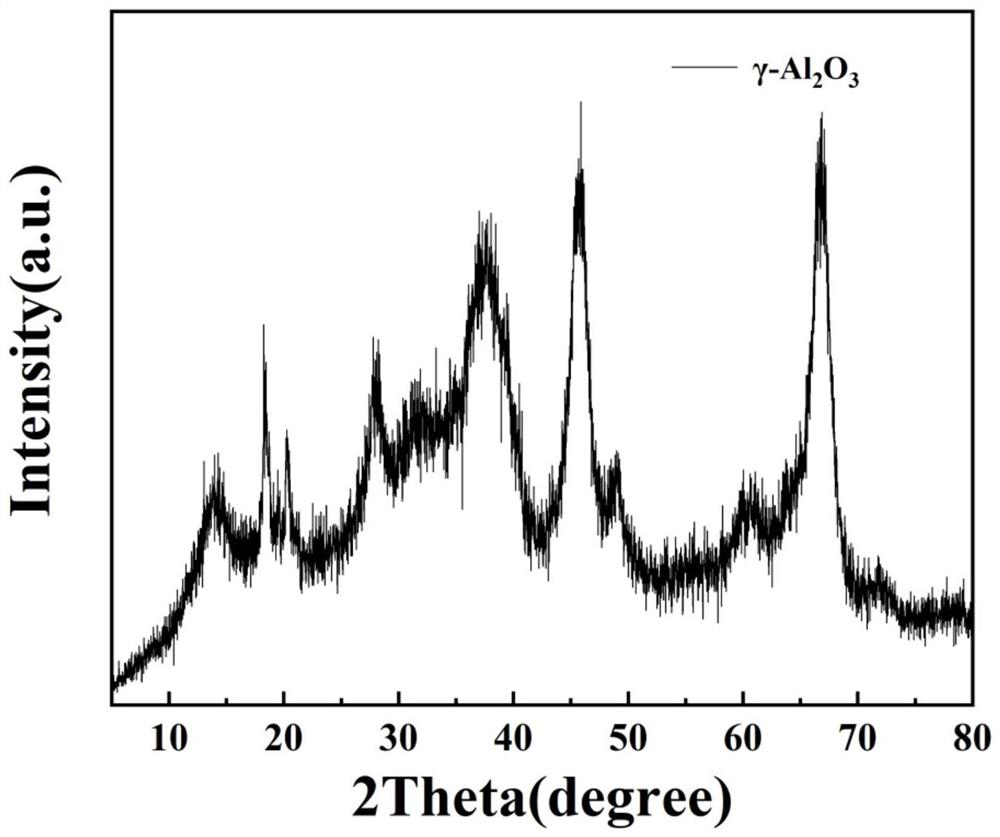

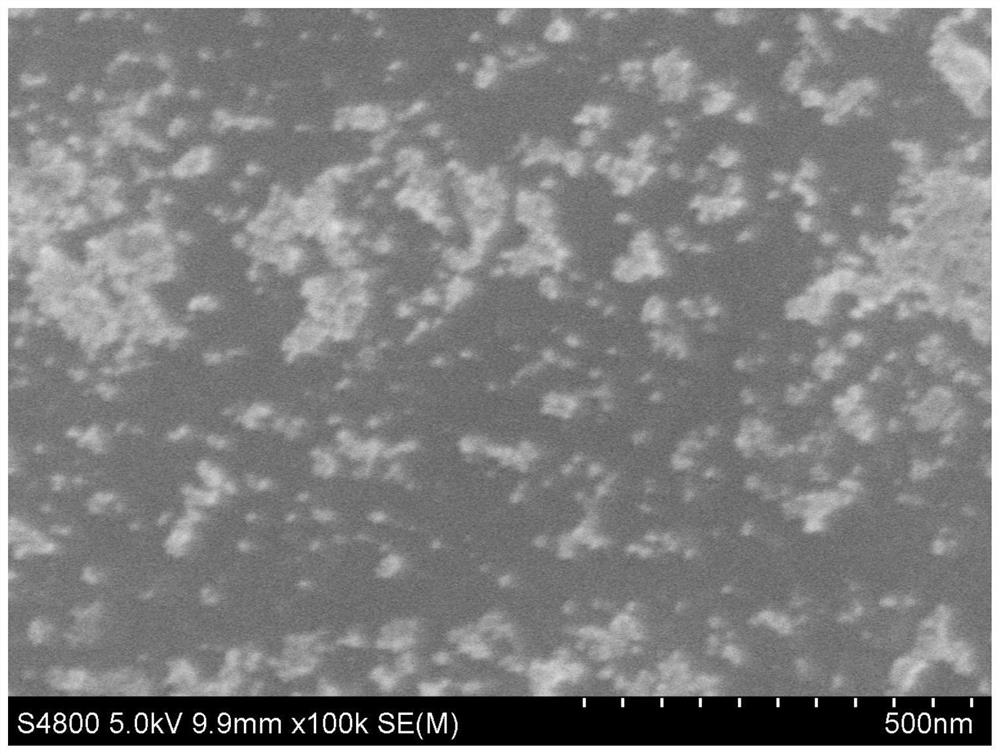

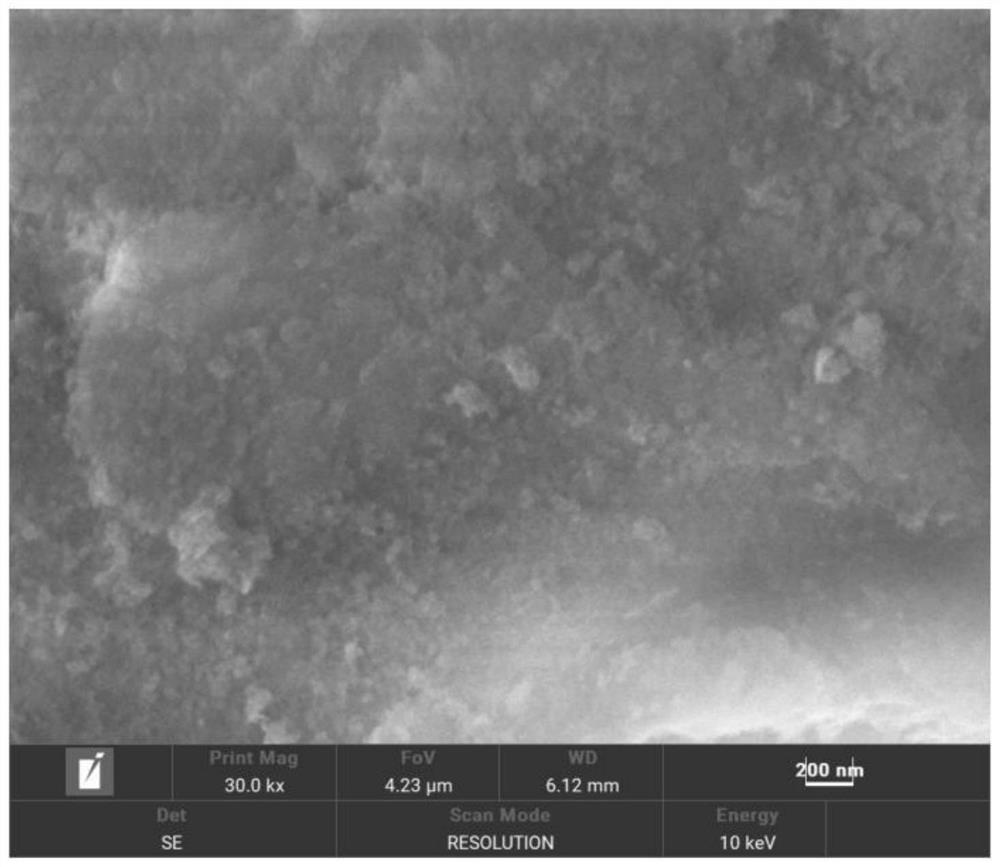

Preparation method of sphere-like nano gamma-aluminum oxide

A kind of alumina, spherical technology, applied in chemical instruments and methods, nanotechnology, nanotechnology and other directions, can solve the problems of equipment and environmental hazards, increase equipment and environmental protection costs, complex preparation process, and meet the equipment requirements. , Easy to use in secondary processing, and the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042]Dissolve 10g of citric acid evenly in 90g of ultrapure water at 60°C, and keep stirring until the citric acid is completely dissolved to form a colorless transparent solution; then add 0.4g of polyethylene glycol and 0.2g of isopropanol, and stir to make it fully Dissolve; take 20g of high-purity boehmite powder, slowly add the boehmite powder while stirring the solution, and continue to stir the solution until all the boehmite is added, continue to stir and disperse evenly; put the obtained slurry Put it into a ball mill and mill it at a speed of 200r / min for 30min, pass the milled slurry through an 80-mesh filter sieve; then spray dry the slurry while stirring, control the spray drying temperature to 110°C, and the feed rate to 500ml / h , to obtain a dry mixture powder; then place the dried mixture powder in a corundum crucible, place the corundum crucible in a muffle furnace, set the heating rate as follows: room temperature to 700°C, the time is 240min, the holding tim...

Embodiment 3

[0046] Dissolve 10g of citric acid evenly in 30g of ultra-pure water at 40°C, and continue to stir until the citric acid is completely dissolved to form a colorless transparent solution; then add 0.2g of polyammonium methacrylate and 0.1g of oleic acid amine, and stir to make it Fully dissolve; take 20g of boehmite powder, slowly add the boehmite powder while stirring the solution, and continue to stir the solution until all the boehmite is added, continue to stir and disperse evenly; put the obtained slurry into Ball mill at a speed of 200r / min for 30min in a ball mill, pass the ball-milled slurry through an 80-mesh filter sieve; then place the slurry in an oven at 100°C and dry it while stirring, and dry the solid obtained after drying with agate Grinding and crushing to a powder with uniform fineness and no graininess to obtain a mixture powder; then place the dried mixture powder in a corundum crucible, put the corundum crucible in a muffle furnace, set the heating rate as:...

Embodiment 4

[0048] Dissolve 10g of glycine evenly in 100g of ultrapure water at 5°C, and keep stirring until the citric acid is completely dissolved to form a colorless transparent solution; then add 0.2g of polyammonium methacrylate and 0.1g of stearic acid, and stir to make it fully Dissolve; take 20g of boehmite powder, slowly add the boehmite powder while stirring the solution, and continue to stir the solution until all the boehmite is added, continue to stir and disperse evenly; put the obtained slurry into a ball mill In the process of ball milling at a speed of 200r / min for 30min, the milled slurry was passed through an 80-mesh filter sieve; then the slurry was spray-dried while stirring, the spray-drying temperature was controlled to be 100°C, and the feed rate was 500ml / h to obtain Dry the mixture powder; then put the dried mixture powder in the corundum crucible, put the corundum crucible in the muffle furnace, set the heating rate as: room temperature to 800°C, the time is 240m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com