A green and efficient nitrogen oxide waste gas treatment method

A nitrogen oxide and waste gas treatment technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of high treatment costs, complex processes, and high equipment costs, reducing treatment costs and simplifying the treatment process. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

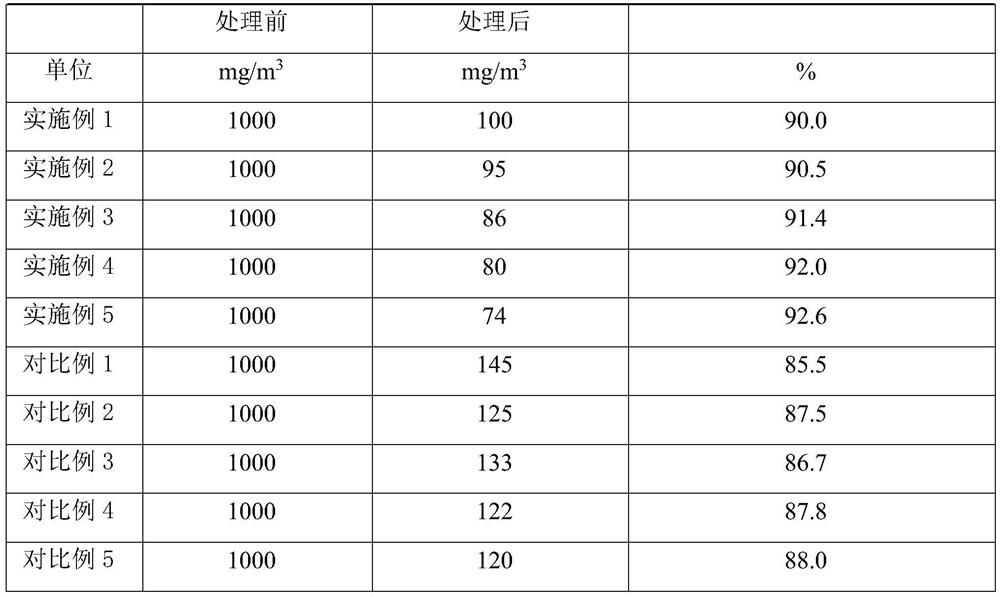

Examples

Embodiment 1

[0023] A green and high-efficiency treatment method for nitrogen oxide waste gas, using a one-step reduction method to treat nitrogen oxide waste gas, passing the nitrogen oxide waste gas into the waste gas treatment tower, and using the nitrogen oxide waste gas treatment liquid to spray the nitrogen oxide waste gas deal with.

[0024] The nitrogen oxide waste gas treatment liquid includes the following components in mass percentage: 1% sodium hydroxide, 10% sodium thiosulfate, 0.5% sodium sulfate, 1% accelerator, and the balance is water.

[0025] The accelerator is prepared from the following raw materials in parts by weight: 20 parts of sodium methoxide, 5 parts of arginine, 30 parts of sucralose ionized trimethylglycine borohydride, 5 parts of glucose, and 10 parts of tetraethylenepentamine.

[0026] The preparation method of the sucralose ionized trimethylglycine borohydride salt comprises the following steps: adding 1kg of sucralose and 1.35kg of tris(hydroxymethyl)methy...

Embodiment 2

[0028] A green and high-efficiency treatment method for nitrogen oxide waste gas, using a one-step reduction method to treat nitrogen oxide waste gas, passing the nitrogen oxide waste gas into the waste gas treatment tower, and using the nitrogen oxide waste gas treatment liquid to spray the nitrogen oxide waste gas deal with.

[0029] The nitrogen oxide exhaust gas treatment liquid includes the following components in mass percentage: 2.5% potassium hydroxide, 13% sodium sulfite, 0.7% sodium borate, 1.5% accelerator, and the balance is water.

[0030] The accelerator is prepared from the following raw materials in parts by weight: 23 parts of potassium ethoxide, 7 parts of arginine, 33 parts of sucralose ionized trimethylglycine borohydride, 7 parts of glucose, and 12 parts of tetraethylenepentamine.

[0031] The preparation method of the sucralose ionized trimethylglycine borohydride salt comprises the following steps: adding 1kg of sucralose and 1.35kg of tris(hydroxymethyl...

Embodiment 3

[0033] A green and high-efficiency treatment method for nitrogen oxide waste gas, using a one-step reduction method to treat nitrogen oxide waste gas, passing the nitrogen oxide waste gas into the waste gas treatment tower, and using the nitrogen oxide waste gas treatment liquid to spray the nitrogen oxide waste gas deal with.

[0034] The nitrogen oxide waste gas treatment liquid includes the following components in mass percentage: 3.5% barium hydroxide, 15% sodium hydrosulfide, 0.8% sodium nitrate, 2% accelerator, and the balance is water.

[0035] The accelerator comprises the following raw materials by weight: 25 parts of potassium tert-butylate, 8 parts of arginine, 35 parts of sucralose ionized trimethylglycine borohydride, 7.5 parts of glucose, tetraethylenepentamine 13 servings.

[0036] The preparation method of the sucralose ionized trimethylglycine borohydride salt comprises the following steps: adding 1kg of sucralose and 1.35kg of tris(hydroxymethyl)methylglycin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com