Preparation method of nano-cerium oxide for silicon slice polishing

A technology for polishing nano-cerium oxide and silicon wafers, which is applied in the direction of chemical instruments and methods, nanotechnology, polishing compositions containing abrasives, etc., can solve the problems of toxic exhaust gas, high cost, and long time period, and meet the requirements of equipment. High, low production cost, narrow particle size distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

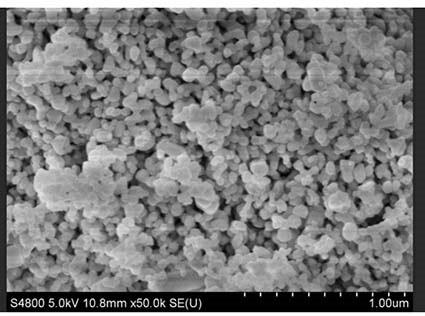

[0022] Dissolve 1.4g of sodium silicate into 2g of ultrapure water, then pour 4.6g of cerium carbonate into the sodium silicate solution while stirring, and obtain a dispersed slurry by ball milling, and then dry it by flash evaporation. Obtain a dry, uniform, and fine mixture powder; then place the mixture powder in a ceramic crucible, put the ceramic crucible in a muffle furnace, and calcine at a temperature of 700°C for 60 minutes; cool down to room temperature with the furnace; A spherical cerium oxide powder of 100-120 nm was obtained. Its scanning electron microscope image is shown in figure 1 shown.

[0023] The prepared 100-120nm cerium oxide is used for polishing silicon wafers, and it is easy to obtain a surface with high flatness without scratching the surface of the polished piece.

Embodiment 2

[0025] Dissolve 0.9g of sodium fluorosilicate into 2g of ultrapure water, then pour 4.6g of cerium carbonate into the sodium fluorosilicate solution while stirring, and obtain a dispersed slurry by ball milling, and then proceed by flash evaporation Dry to obtain a dry, uniform and fine mixture powder; then place the mixture powder in a ceramic crucible, put the ceramic crucible in a muffle furnace, calcining at 800°C for 30 minutes; cool to room temperature with the furnace; A spherical cerium oxide powder of 100-120 nm can be obtained.

[0026] The prepared 100-120nm cerium oxide is used for polishing silicon wafers, and it is easy to obtain a surface with high flatness without scratching the surface of the polished piece.

Embodiment 3

[0028] Dissolve 1.4g of sodium silicate into 2g of ultrapure water, then pour 5.4g of cerium oxalate into the sodium silicate solution while stirring, and obtain a dispersed slurry by ball milling, and then dry it by flash evaporation. Obtain a dry, uniform, and fine mixture powder; then place the mixture powder in a ceramic crucible, put the ceramic crucible in a muffle furnace, and calcine at a temperature of 700°C for 60 minutes; cool down to room temperature with the furnace; A spherical cerium oxide powder of 100-120 nm was obtained.

[0029] The prepared 100-120nm cerium oxide is used for polishing silicon wafers, and it is easy to obtain a surface with high flatness without scratching the surface of the polished piece.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com