Flue gas purification device

A flue gas purification and tracheal technology, which is applied in the field of flue gas treatment, can solve the problem that the flue gas cannot be completely purified, and achieve the effect of improving the filtering effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

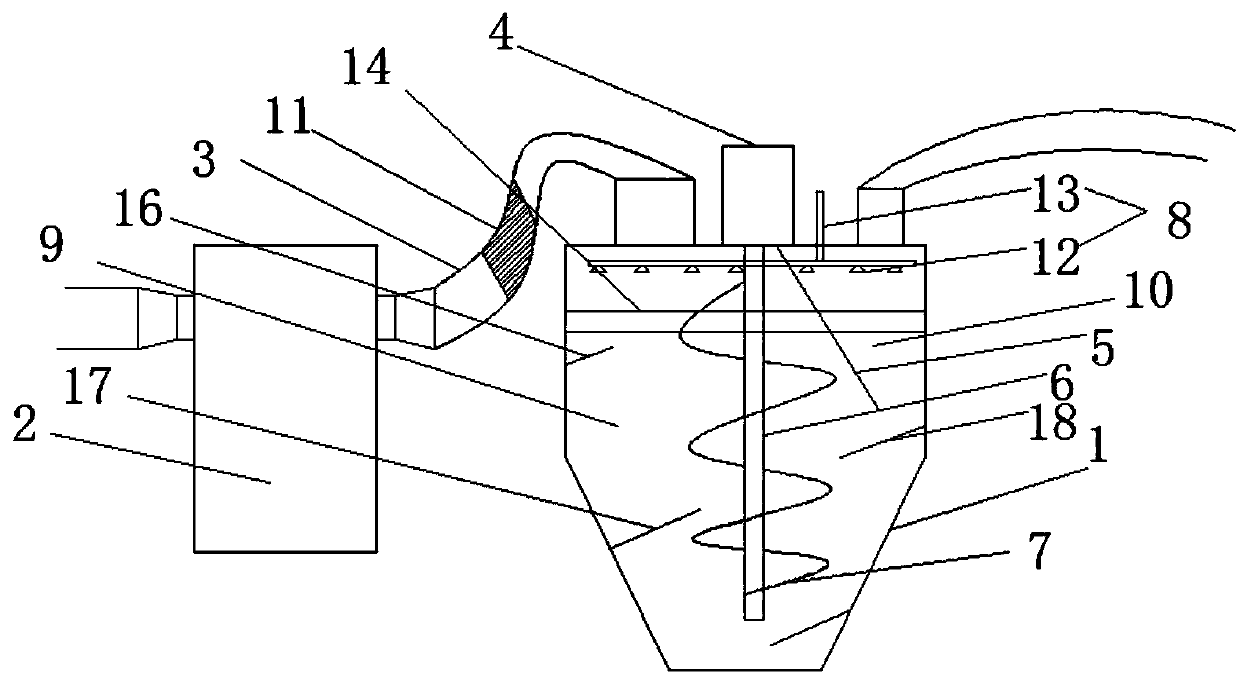

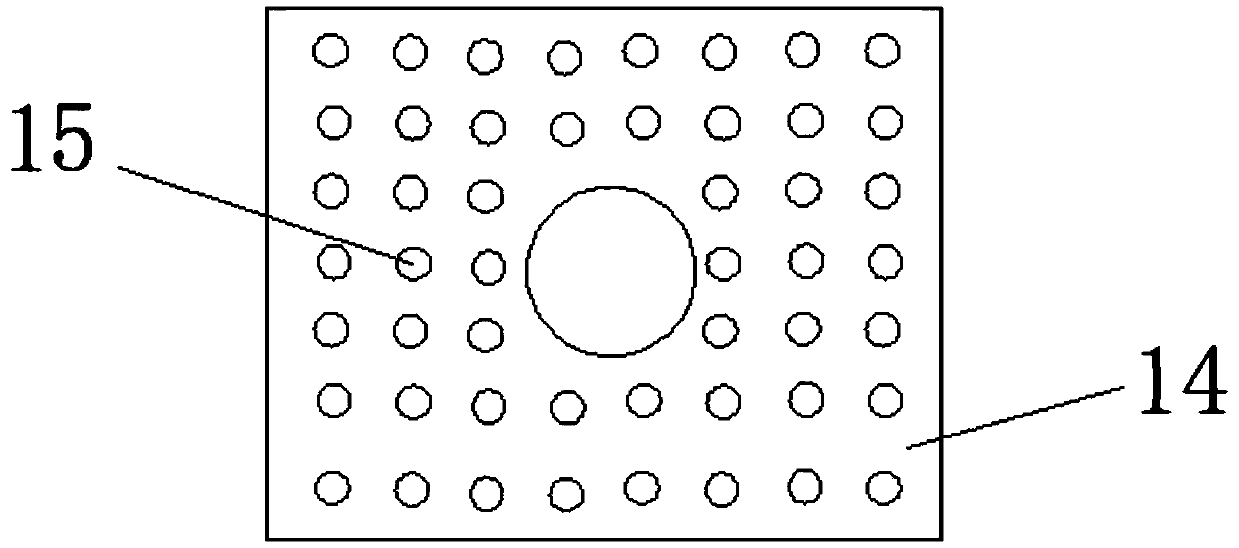

[0026] Such as figure 1 As shown, a flue gas purification device provided by the present invention includes a treatment cylinder 1 and an electrostatic precipitator 2. The electrostatic precipitator 2 communicates with the top of the treatment cylinder 1 through a gas pipe 3. On the treatment cylinder 1 A stirring motor 4 is installed, and the inside of the processing cylinder 1 is provided with an inclined baffle plate 5, the stirring shaft 6 is installed on the stirring motor 4, the stirring blade 7 is installed on the stirring shaft 6, and the inside of the processing cylinder 1 is arranged There is a purification mechanism 8; the electrostatic precipitator 2 is used for the first step of treatment, and the treatment cylinder 1 is used for the second step of treatment.

[0027] Such as figure 1 As shown, the baffle plate 5 divides the processing cylinder 1 into a processing chamber 9 and an air outlet chamber 10. The area of the processing chamber 9 is twice the area of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com