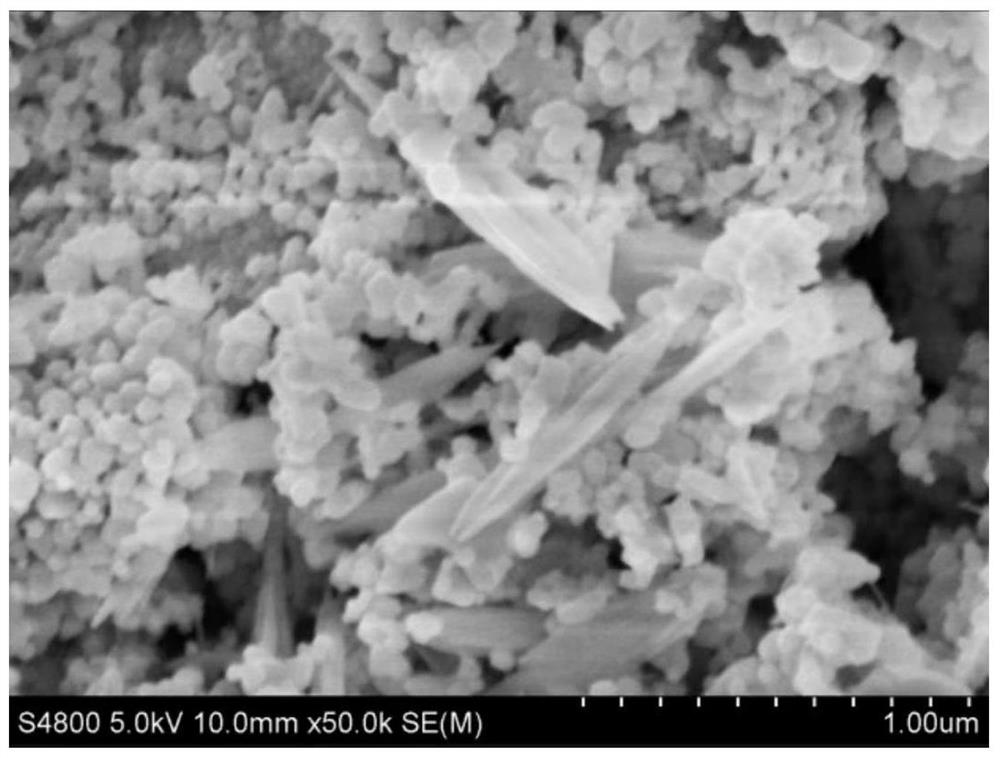

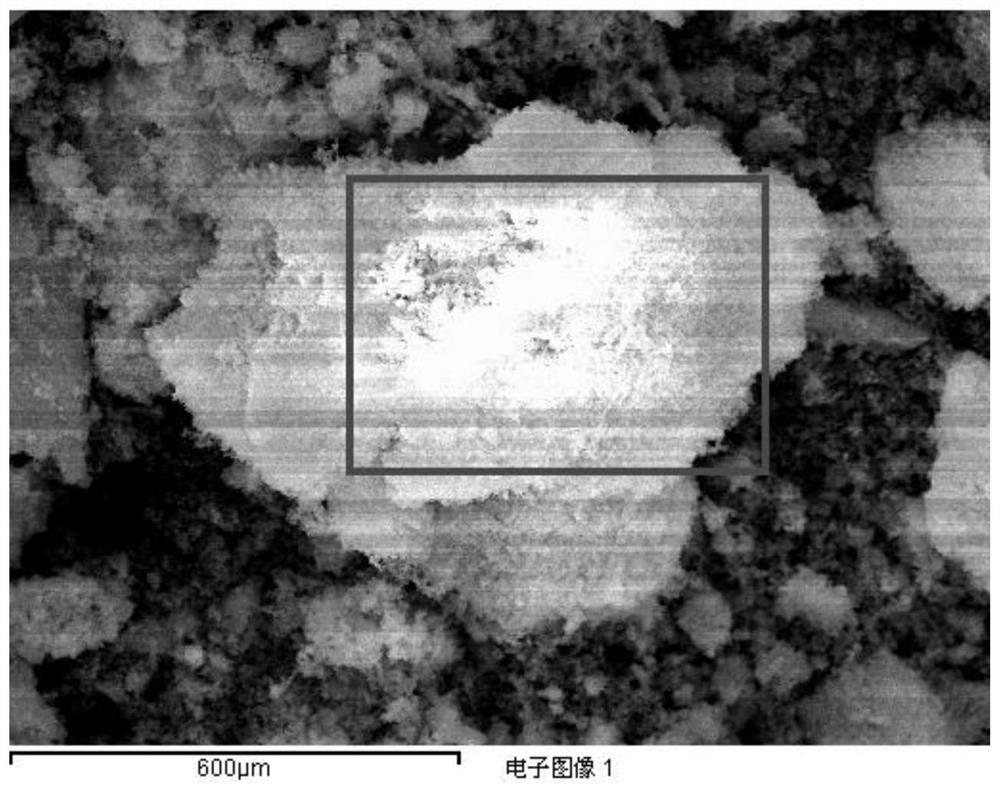

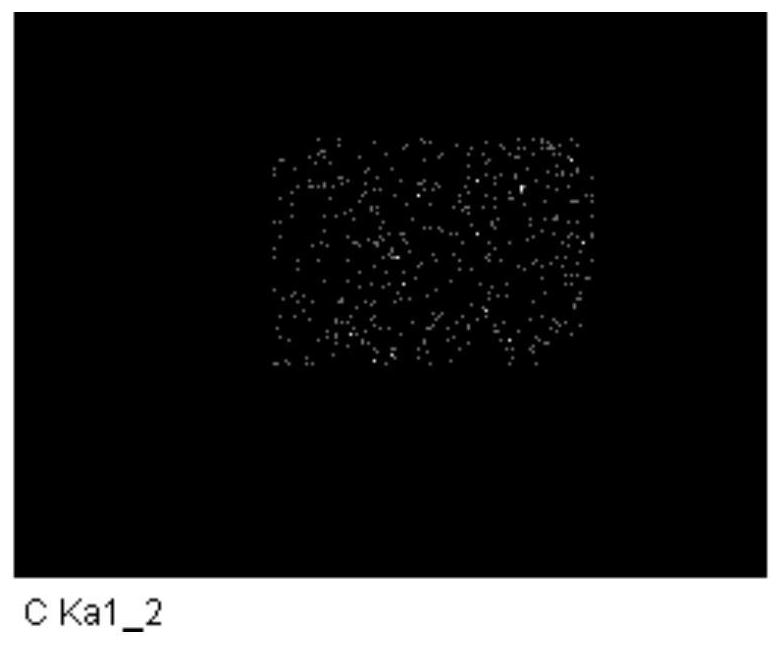

Preparation method of nano cerium oxide-graphene composite particles

A graphene composite, nano-cerium oxide technology, applied in chemical instruments and methods, nanotechnology, nanotechnology and other directions, can solve the problems of complex procedures, many process steps, particle growth, etc., and achieves simple process method and easy absorption and treatment. , the effect of narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of nano cerium oxide-graphene composite particles, comprising the following steps:

[0030] (1) Ultrasonic dispersion of 2 g of cerium oxide in 100 mL of semiconductor ultrapure water, and spray drying of the dispersion solution to obtain cerium oxide micropowder with a water content lower than 1%;

[0031] (2) The obtained cerium oxide micropowder was dispersed in 100 mL of hydrogen peroxide solution with a mass fraction of 28% by ultrasonic stirring, ultrasonically dispersed for 60 min, polyvinylpyrrolidone was added, and dispersed for 60 min again to obtain a surface-treated cerium oxide suspension;

[0032] (3) Get 0.4g of 0.5% thick graphene solution and disperse it in 25mL absolute ethanol, and ultrasonically disperse it for 60min to obtain graphene suspension;

[0033] (4) Add the obtained graphene suspension to the cerium oxide suspension, mix uniformly, add 2g of BPO solid powder, and disperse ultrasonically at room temperature for 120min, ...

Embodiment 2

[0039] A preparation method of nano cerium oxide-graphene composite particles, comprising the following steps:

[0040] (1) Take 2g of cerium oxide in 100mL of semiconductor ultrapure water for ultrasonic stirring and dispersion, and spray dry the dispersion solution to obtain cerium oxide micropowder with a water content lower than 1%;

[0041] (2) Stir and disperse the obtained cerium oxide micropowder in 100 mL of hydrogen peroxide solution with a mass fraction of 28% with a stirring rod, stir and disperse with a stirring rod at room temperature for 60 min, add polyvinylpyrrolidone, and disperse for 60 min again to obtain surface-treated cerium oxide suspension;

[0042] (3) Get 0.4g of 0.5% thick graphene solution and disperse it in 25mL absolute ethanol, and ultrasonically disperse it for 60min to obtain graphene suspension;

[0043] (4) Add the obtained graphene suspension to the cerium oxide suspension, mix uniformly, add 2g of BPO solid powder, and disperse ultrasonic...

Embodiment 3

[0048] A preparation method of nano cerium oxide-graphene composite particles, comprising the following steps:

[0049] (1) Take 2g of cerium oxide in 100mL semiconductor ultrapure water and stir with a stirring rod to disperse, spray dry the dispersion solution, and obtain cerium oxide micropowder with a water content lower than 1%;

[0050] (2) Disperse the obtained cerium oxide micropowder in 100 mL of hydrogen peroxide solution with a mass fraction of 28% in a sander, stir and disperse the emulsifier at room temperature for 60 minutes, add polyvinylpyrrolidone, and disperse again for 60 minutes to obtain a surface-treated cerium oxide suspension liquid;

[0051] (3) Get 0.4g of 0.5% thick graphene solution and disperse it in 25mL absolute ethanol, and ultrasonically disperse it for 60min to obtain graphene suspension;

[0052] (4) Add the obtained graphene suspension to the cerium oxide suspension, mix uniformly, add 2g of BPO solid powder, and disperse ultrasonically at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com