Vertical type blotter press

A vertical filter press, filter press technology, applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of increasing the power of the hydraulic pump station of the equipment, many safety hazards, failure of solenoid valves, etc., to achieve hydraulic pressure Improvement of leaks and malfunctions of solenoid valves, cost improvement, and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

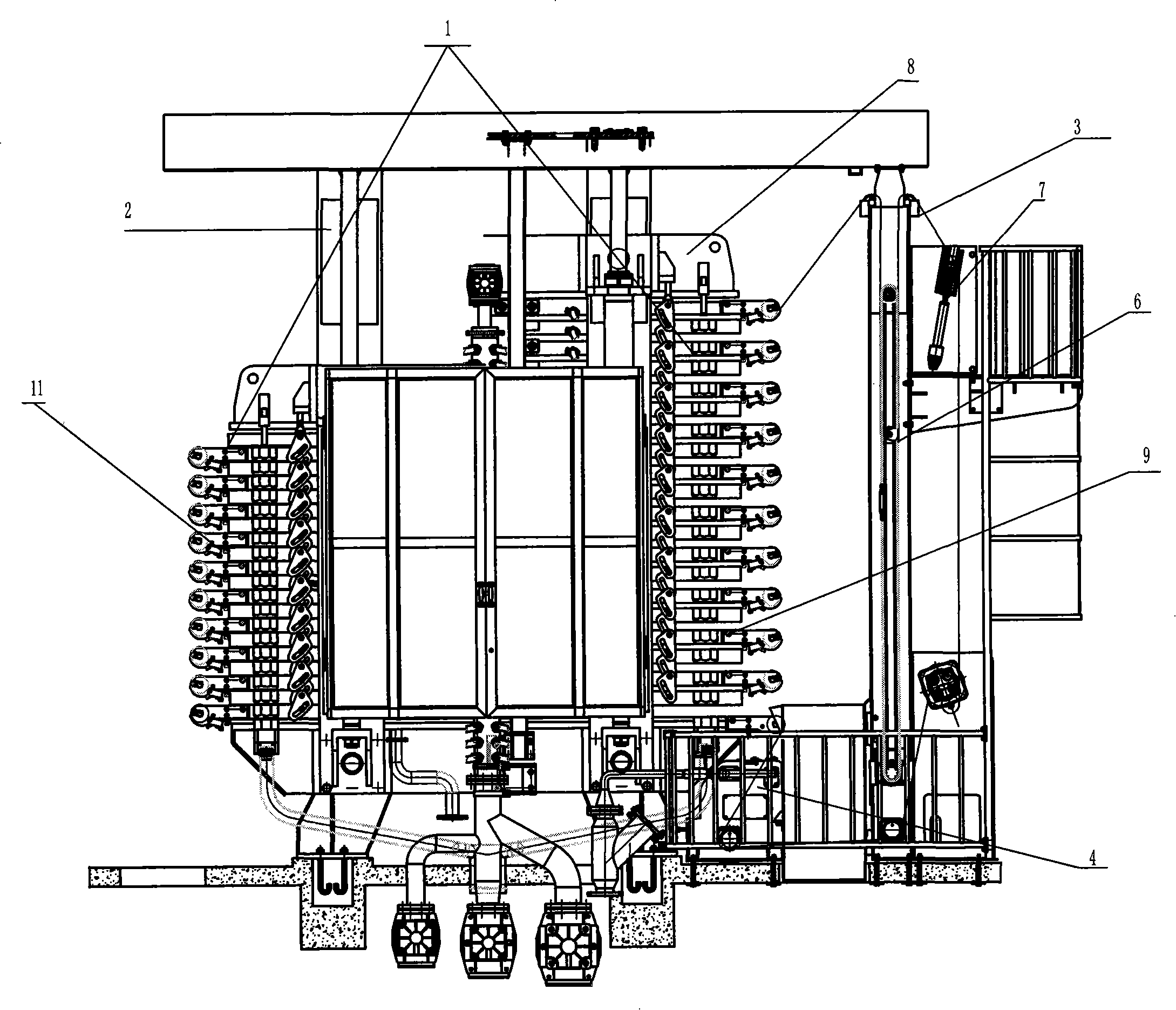

[0026] Such as figure 1 As shown, the main support 2 of the filter press is equipped with a multi-layer plate frame, and the opening and compression of the plate frame group 1 is realized by the hydraulic system 6 located on the support, and the hydraulic system includes a hydraulic pump station. The cleaning of the filter cloth 5 is controlled by the filter cloth automatic control walking system 3 , which system includes a deviation correction device 7 and a cleaning device 4 . The operation of the entire filter press system is monitored by an automatic control system, which includes an independent operating platform and a main electric control cabinet.

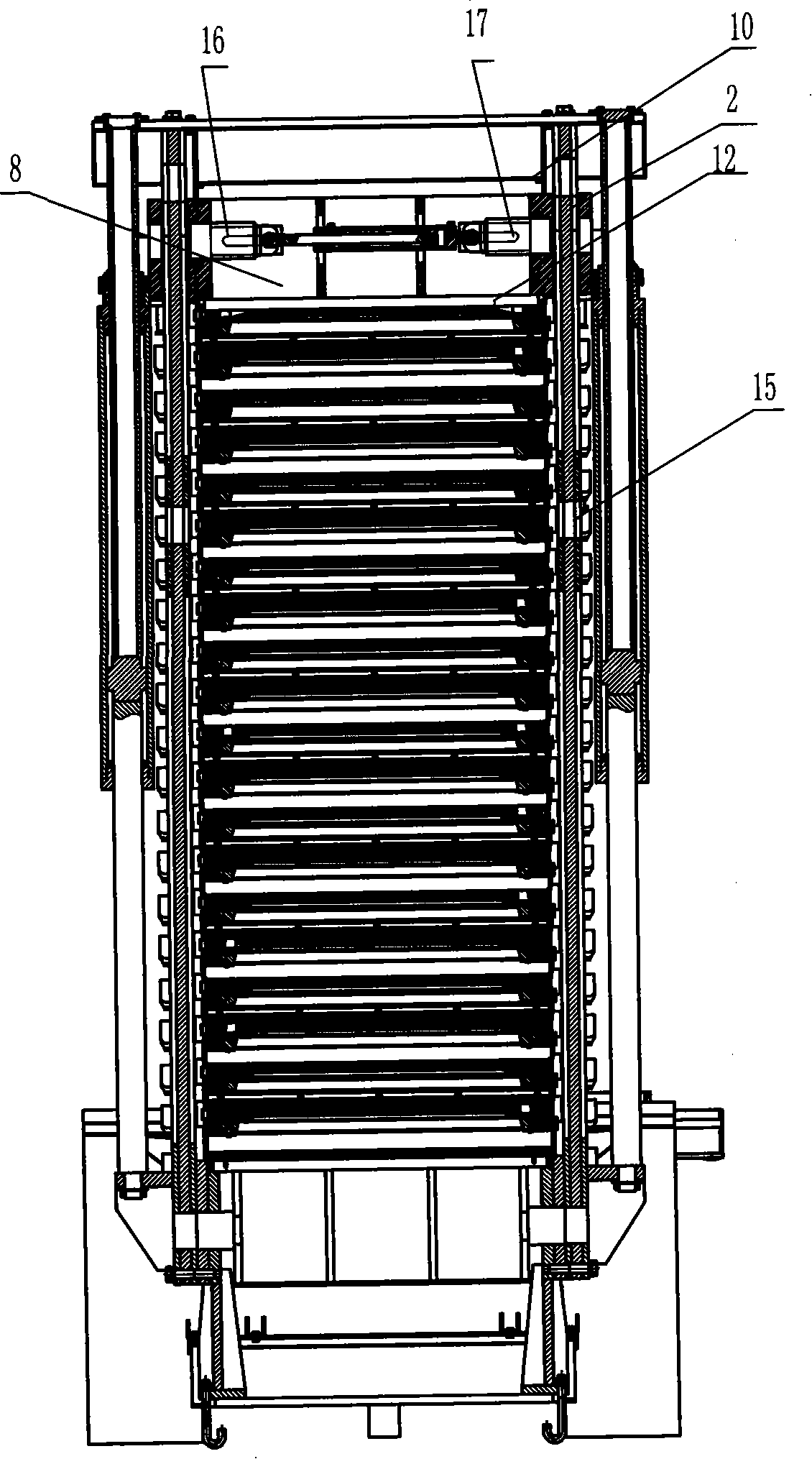

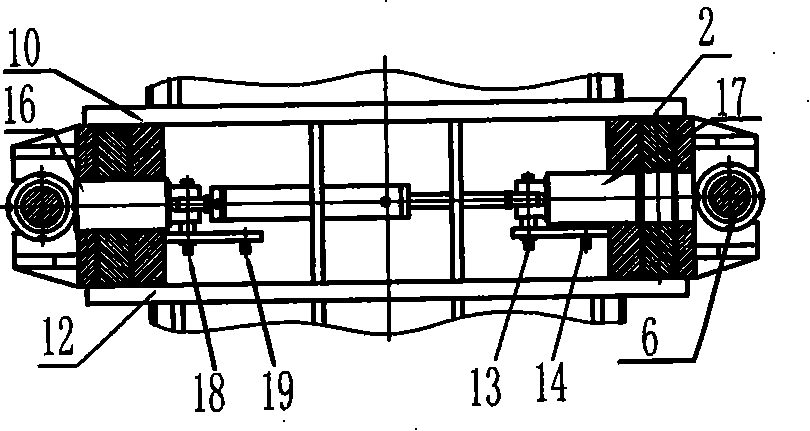

[0027] Such as figure 2 , 3 As shown, when the filter press is working, the filtered liquid needs to enter the plate and frame group 1. When each filter chamber is full, the plate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com