Turntable structure of ultrathin overlaid filtering layer vertical filter press

A vertical filter press and turntable technology, which is applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve problems such as reduced efficiency, and achieve the effects of improving production efficiency and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The rotary disc structure of the ultra-thin superimposed filter layer vertical filter press according to the present invention will be described in detail below with reference to the accompanying drawings and embodiments.

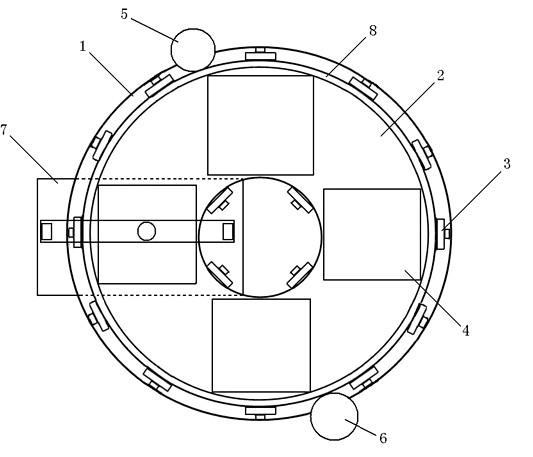

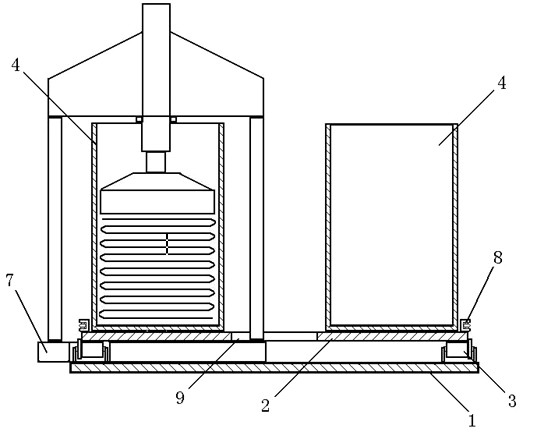

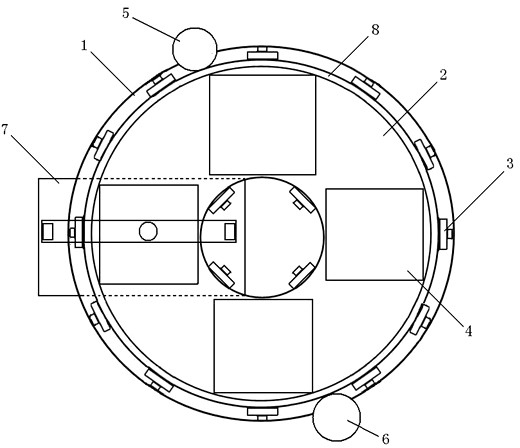

[0022] figure 1 A top view of the turntable structure of the ultra-thin superimposed filter layer vertical filter press; figure 2 It is a vertical sectional view of the turntable structure of the ultra-thin superimposed filter layer vertical filter press of the present invention. like figure 1 and figure 2 As shown, the turntable structure of the ultra-thin superimposed filter layer vertical filter press according to the present invention includes a chassis 1 and a turntable 2 arranged above the chassis 1 . The turntable 2 is ring-shaped, with an outer diameter of 4-5m, an inner diameter of 1-1.5m, and a thickness of 20-30mm. An inner hole 9 is formed in the center, and twelve supporting wheels 3 are uniformly arranged along the outer diameter o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com