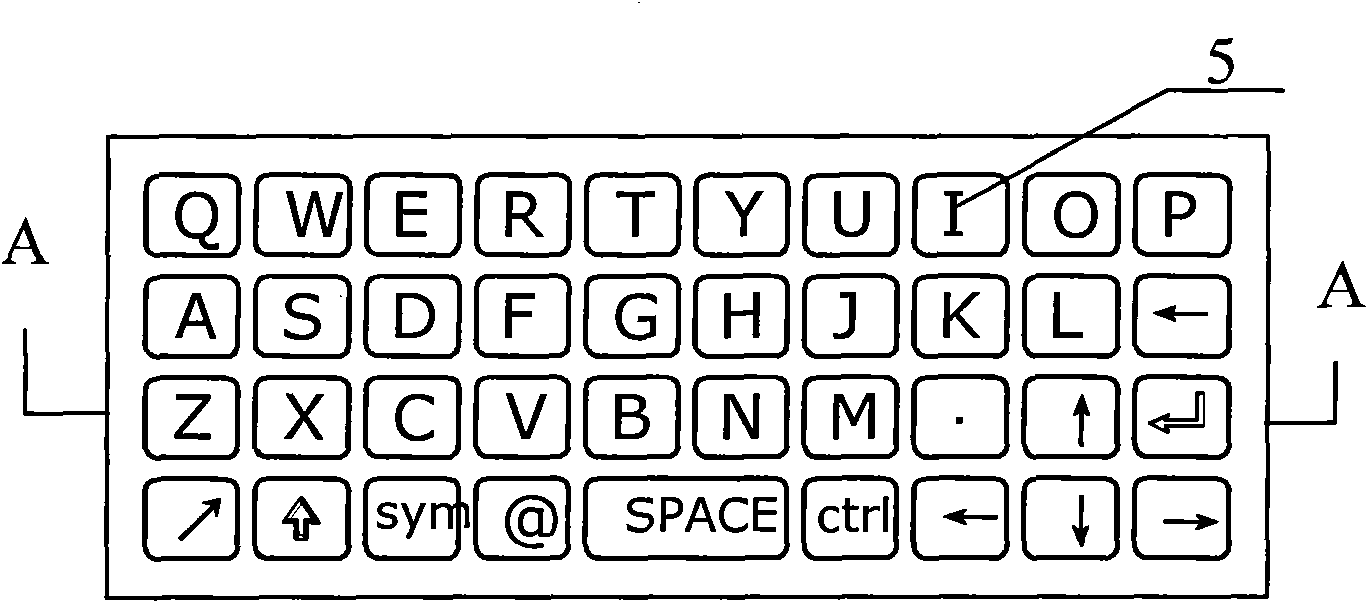

Full keyboard components, manufacturing method and full keyboard thereof

A production method and technology of a full keyboard, applied to electrical components, electric switches, circuits, etc., can solve the problems of insufficient rigidity of the full keyboard assembly, unstable production, thick full keyboard, etc., and achieve good rigidity, high production efficiency, and benefit reduction. thin effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment is used to illustrate the full keyboard assembly provided by the present invention and its manufacturing method.

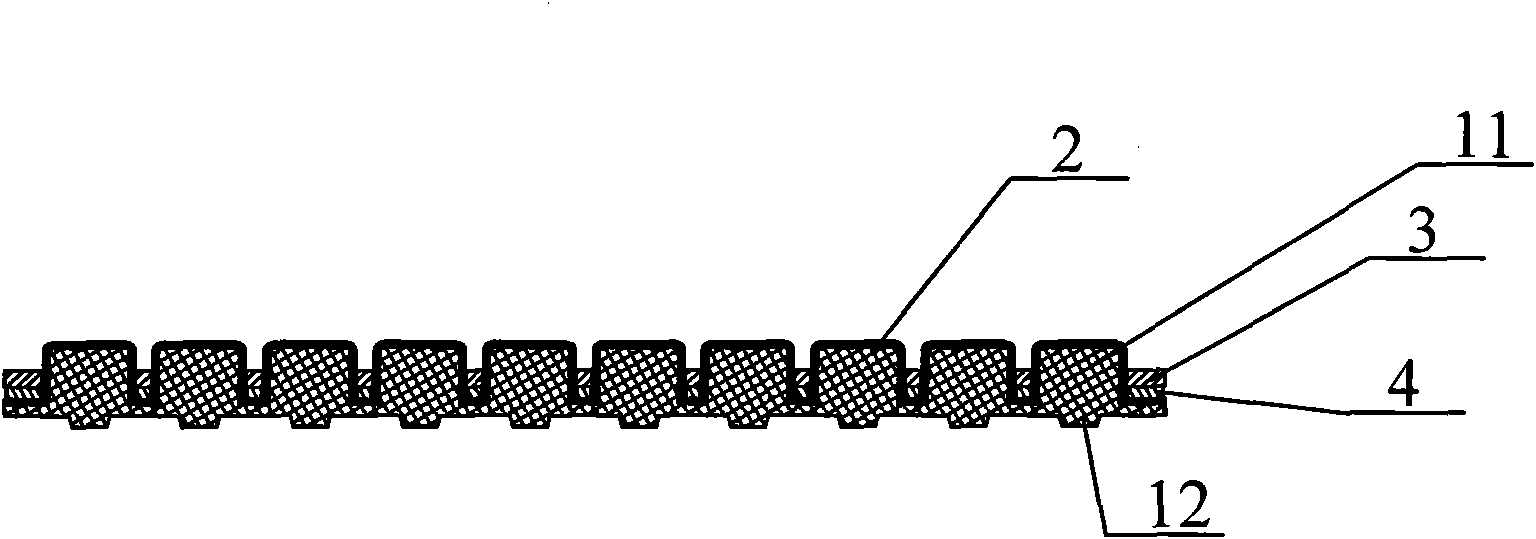

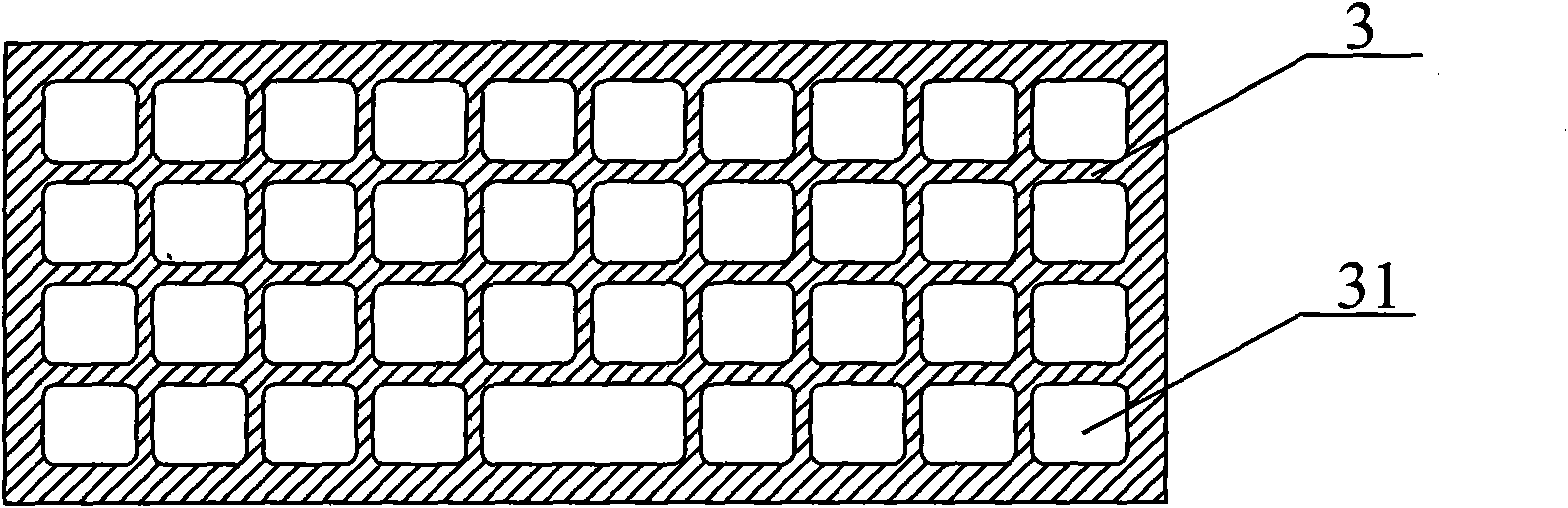

[0041] Use the method of screen printing to print anti-stretch white ink (Seiko, IUX series) on one surface of a TPU film with a size of 275 × 170 × 0.15mm, forming such as figure 1 The pattern shown in 5, and then use the screen printing method to print black ink (Japanese Imperial ink, INQ-971) on the same surface of the TPU film, and then perform far-infrared baking on the formed ink layer , the baking temperature is 100° C., and the baking time is 10 minutes.

[0042] Coat liquid silicone (Zhongshan Polymer Electronic Materials Co., Ltd., 9150A and 9150B) on the surface of the above TPU sheet (that is, the side where the ink is printed), put the silicone-coated side up, and put the TPU together with the silicone into the concave mold , close the mold after setting the position, and apply 120kg / cm to the mold through the molding machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com