500 MPa level high-nitrogen composite microalloyed steel bar and production method thereof

A technology of micro-alloying and steel bar, which is applied in the field of steel bar and its production, can solve the problems of increased production cost of steel bar, poor castability of molten steel, rising and other problems, and achieve low requirements for rolling mill equipment capacity, good castability of molten steel, and reduced The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

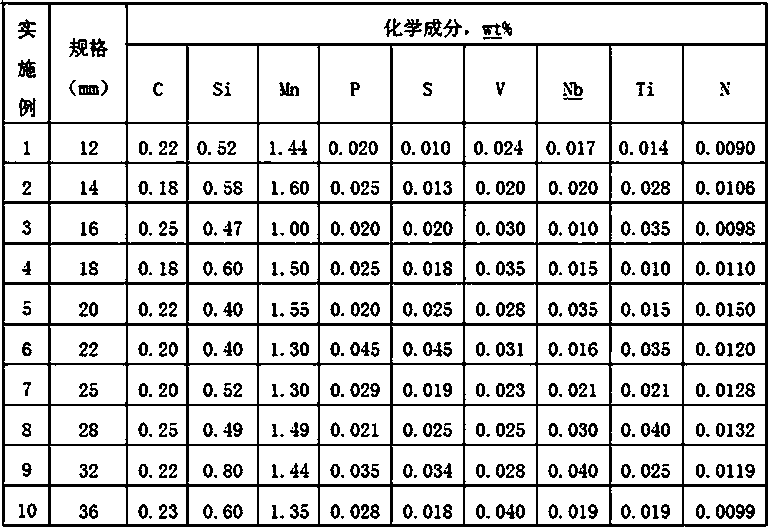

[0016] The present invention will be further described below through Examples 1-10.

[0017] In Examples 1 to 10, ferroniobium and ferrovanadium nitride are used for deoxidation and alloying in the tapping process, and the molten steel after tapping is sent to the refining furnace for refining and fine-tuning of the composition according to the elements and contents specified in Table 1. Cast into 150mm square billet;

[0018] Table 1 Chemical composition list

[0019]

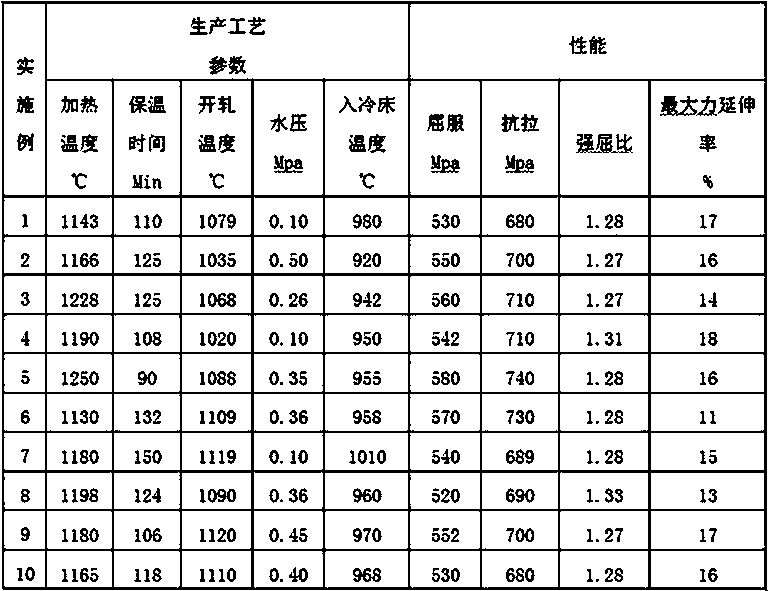

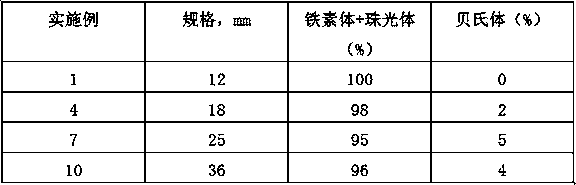

[0020] The 150 square billet passes through the bar heating furnace to control the heating temperature of 1130-1250°C, and then heats it for 90-150 minutes, and then cools down to 1020-1120°C for rolling. After rolling, it is water-cooled, the water pressure is 0.1-0.5Mpa, and the upper cooling is controlled. The bed temperature is 920-1010°C, the steel bars are naturally cooled after entering the cooling bed, then cut, bundled, and put into storage; the process parameters and properties are shown in Table...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strong bend ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com