Device for forming tin electrode wire on solar cell sheet

A solar cell and electrode wire technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as increased equipment investment costs, inability to weld quickly, and limit the feasibility of mass production of ultrasonic welding processes, and achieve equipment costs. Low, mass production stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The welding principle of the present invention is: using ultrasonic welding technology to provide ultrasonic energy to the welding head, the welding head is pre-heated and continuously heated, and the solder wire touches the welding head and melts instantaneously. When the welding head touches the substrate (silicon wafer), the melted tin is transferred to the substrate to form a firm bond under the action of ultrasonic waves. When the substrate (silicon wafer) or the welding head moves continuously, a tin line can be formed on the substrate (silicon wafer). The infrared heating technology of the present invention can quickly preheat the substrate (silicon chip), and can locally heat the welding area to the required temperature, while the ambient temperature remains unchanged.

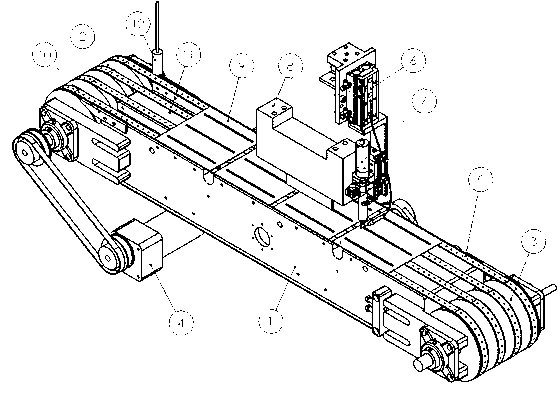

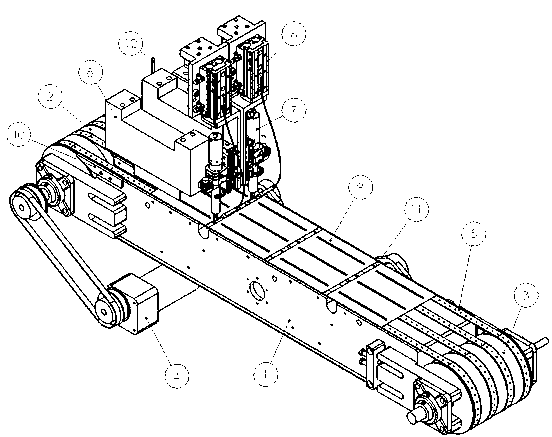

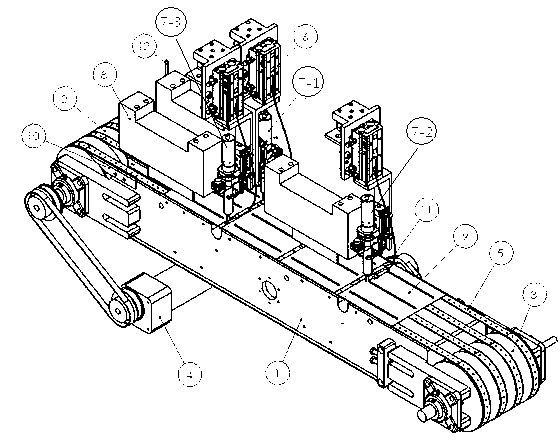

[0026] According to above-mentioned principle, the present invention provides a kind of device that forms tin electrode line on solar battery sheet, as follows:

[0027] The device includes a v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com