Liquid crystal medium mixture and liquid crystal display using same

A technology of liquid crystal medium and mixture, applied in liquid crystal materials, instruments, chemical instruments and methods, etc., can solve the problems of slow reaction speed, insufficient polymer alignment force, strong alignment force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

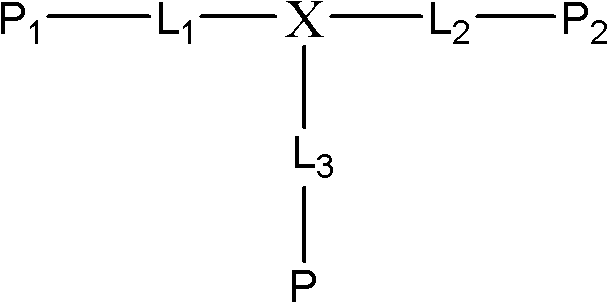

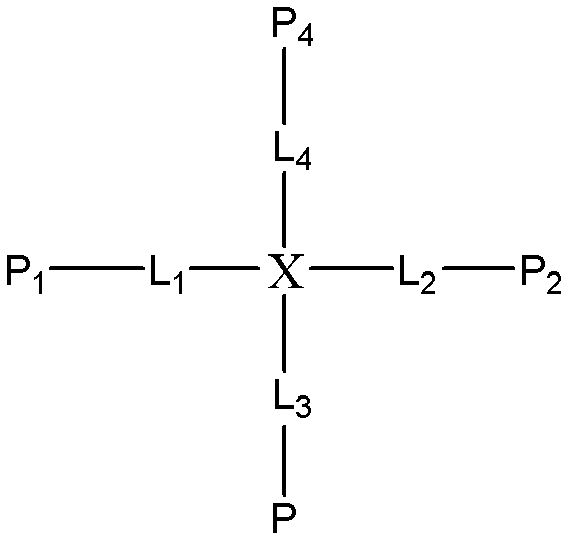

[0095] Using a negative type liquid crystal material, its T ni is 75°C, Δn is 0.095 (25°C, 589nm), and Δε is -2.8 (25°C, 1kHz). If a certain amount of the fast-response monomer and strong alignment monomer described in the present invention are mixed into the liquid crystal material, then The desired mixture of liquid-crystalline media is obtained. The content molar ratio of the fast-response type monomer and the strong alignment type monomer is 20:100, and the total weight of the two accounts for 0.35% of the weight of the liquid crystal material. The structure of the fast-response monomer used therein is as follows, and its molecular weight is 330:

[0096]

[0097] The structure of the strong alignment monomer used is as follows, and its molecular weight is 312:

[0098]

[0099] The liquid crystal medium mixture is dropped on the prepared TFT Array substrate by ODF (One Drop Filling liquid crystal dripping) method, and combined with the CF substrate. After curing t...

Embodiment 2-5

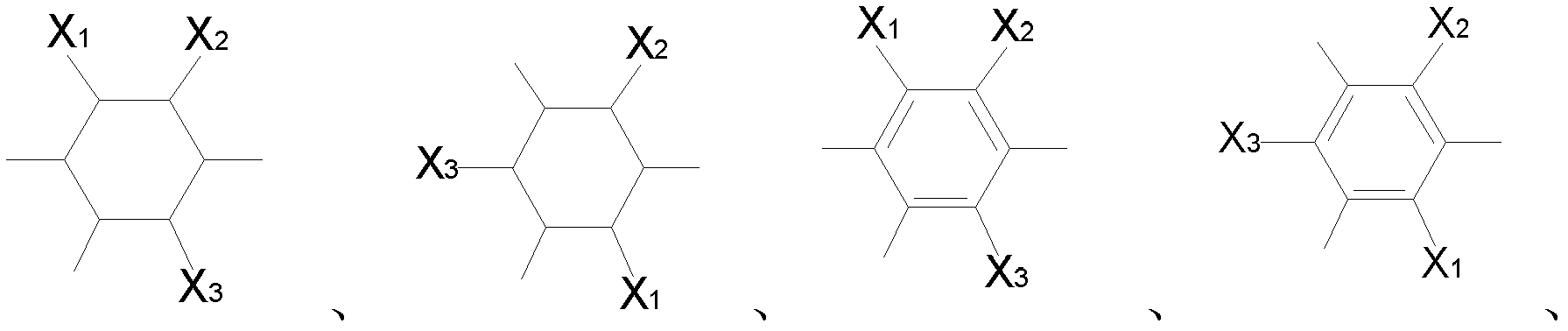

[0101] Referring to Example 1, the difference lies in the structure and content of the fast-reaction type monomer and the strong alignment type monomer, see Table 1 below for details.

[0102] Table 1. The structure and content table of the fast-response type monomer and the strong alignment force type monomer of embodiment 2-5

[0103]

[0104] In summary, the liquid crystal medium mixture of the present invention adopts two or more polymerizable monomers with different functionalities for reasonable matching, and the reaction speed of the polymerization reaction, the uniformity of the formed polymer and the strength of the alignment force can be At the same time to achieve a balance, and all get a higher level. With liquid crystal displays using it, the optical quality and overall performance of the panel are improved, and stable mass production can be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com