Curved surface display panel

A curved surface display and panel technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of large relative movement, unevenness, and degradation of display quality between the light-shielding part and the pixel electrode, and achieve the effect of improving optical taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

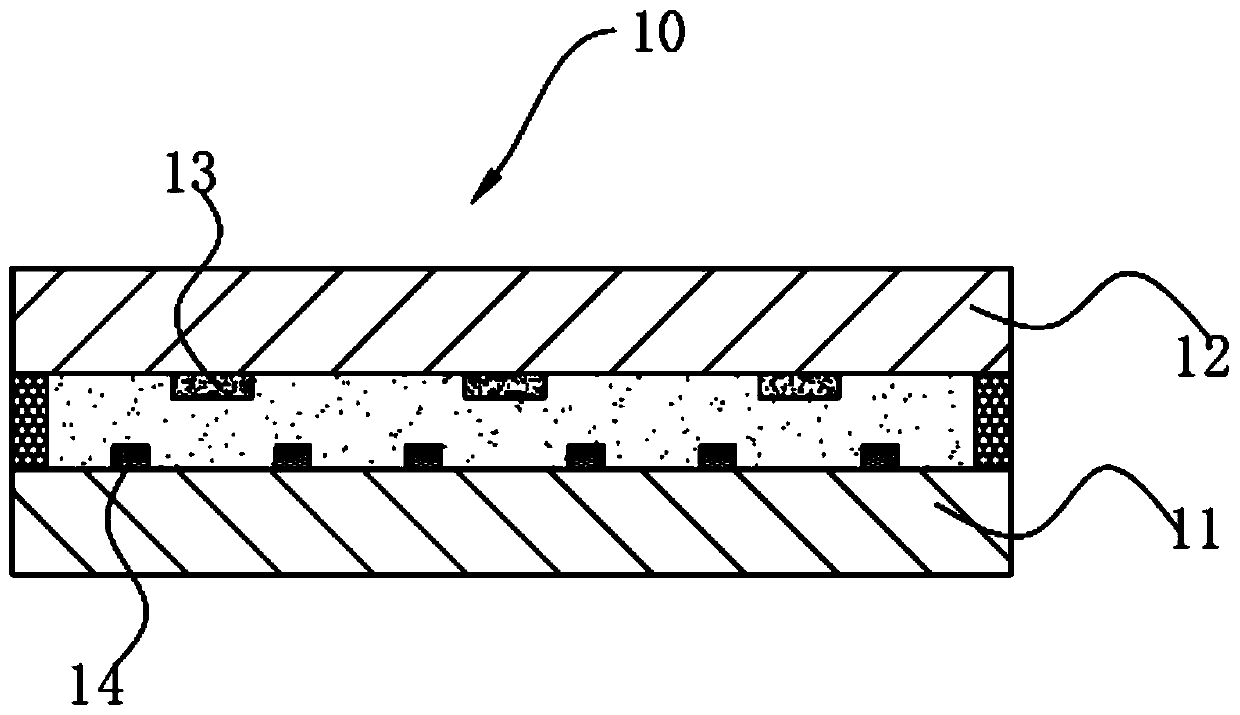

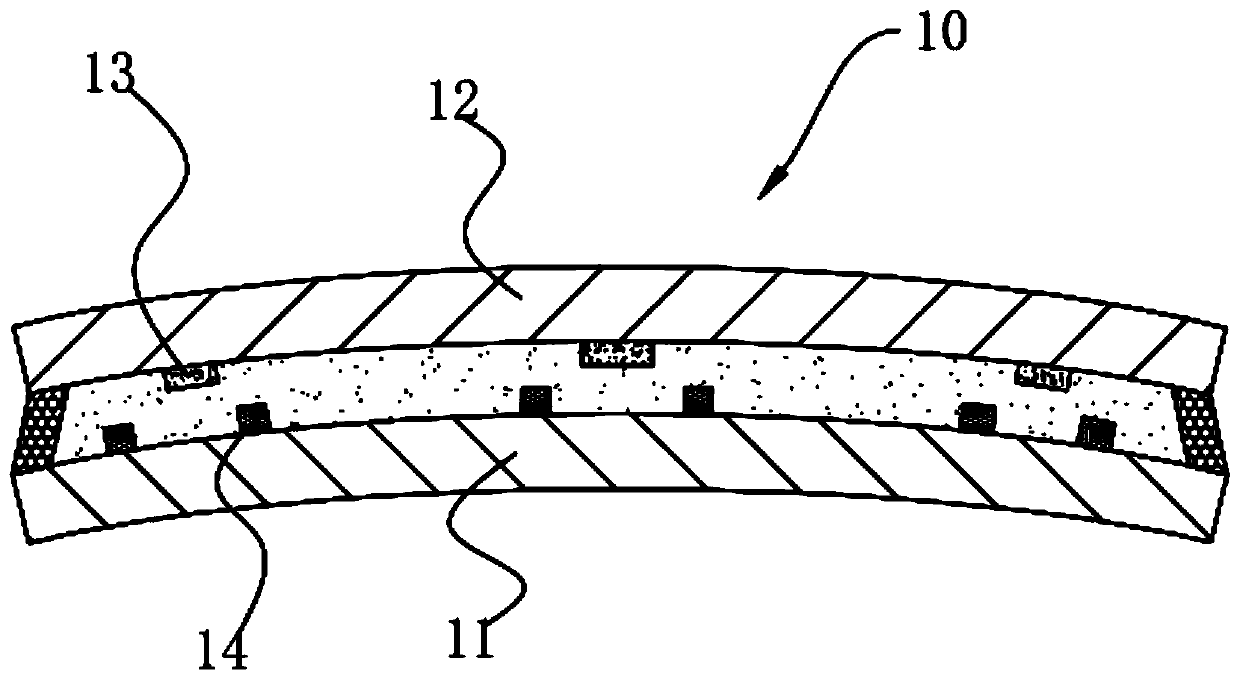

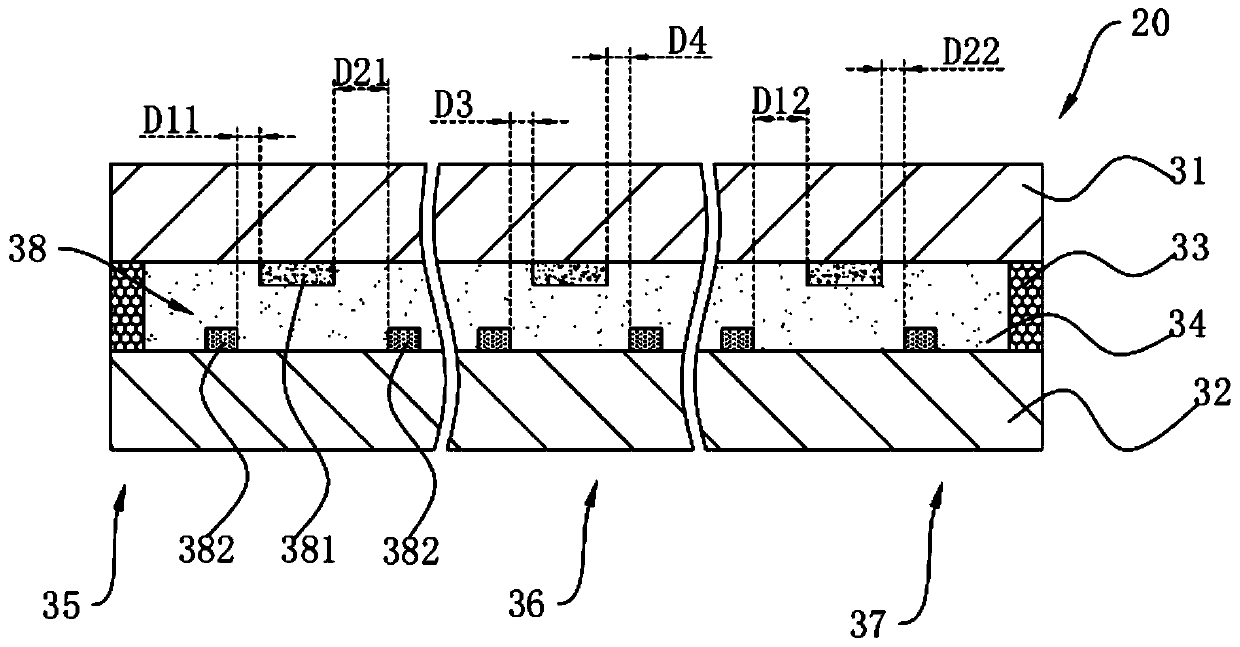

[0034] A curved display panel such as image 3 and Figure 4 As shown, the curved display panel 30 is formed by bending the flat display panel 20; the curved display panel 30 includes a curved color filter substrate 32, a curved surface array substrate 31, and The liquid crystal layer 34 on the 31 and the sealant 33; the sealant 33, the curved color filter substrate 32 and the curved array substrate 31 directly form an accommodating chamber for accommodating the liquid crystal layer 34.

[0035] Specifically, the side of the curved color filter substrate 32 away from the curved array substrate 31 is the light emitting surface of the curved display panel 30 , and the light emitting surface of the curved display panel 30 is a concave surface.

[0036] Specifically, a black matrix and a plurality of sub-pixels arranged at intervals are arranged between the curved surface array substrate 31 and the curved color filter substrate 32, and the black matrix includes light-shielding el...

Embodiment 2

[0062] A curved display panel such as Figure 7 and Figure 8 As shown, the difference from Embodiment 1 is that the display surface of the curved display panel 30 is convex.

[0063] Specifically, when the curved display panel 30 is in a flattened state, D21 is smaller than D11, and D12 is smaller than D22.

[0064] It should be noted that those skilled in the art know that when the light-emitting surface of the curved display panel 30 is convex, during the process of bending the flat display panel 20 into the curved display panel 30, the left end of the curved array substrate 31 moves relatively to the left, and the right end Relatively move to the right; when the curved display panel 30 is in a flattened state, D21 is set to be smaller than D11, and D12 is smaller than D22. When the flat display panel 20 is bent into a curved display panel 30, displacement compensation is used to make D21 equal to or D11 is approximately equal to D12, and D12 is equal to or approximately ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com