Backlight module and spraying jig

A technology of backlight module and backlight assembly, applied in optics, light source, shading, etc., can solve the problems of narrow double-sided tape width, affecting the frame size of display products, etc., and achieve the effect of solving complex process and improving optical taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

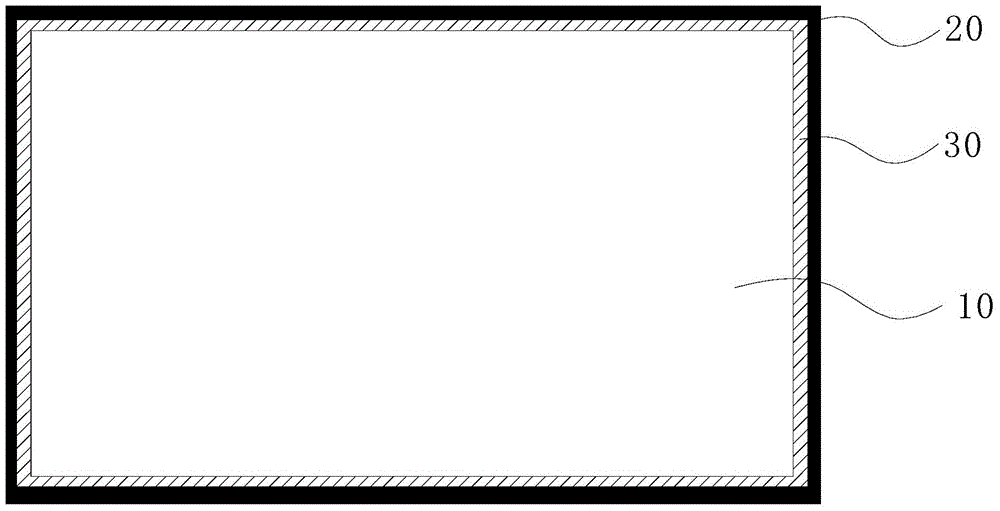

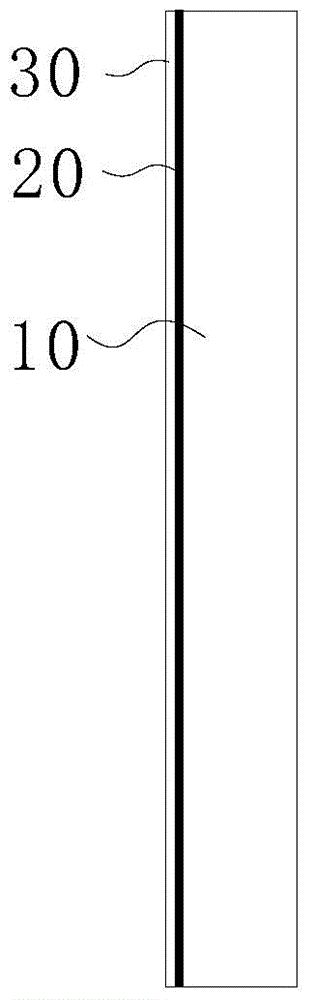

[0019] refer to figure 1 with figure 2 The present invention provides a backlight module, including a backlight assembly 10 for generating backlight, the upper surface of the backlight assembly 10 is an optical film, and a layer of light-shielding layer 20 is sprayed around the upper surface of the optical film.

[0020] The light-shielding layer 20 is formed on the periphery of the uppermost layer of the optical film of the backlight assembly 10 for absorbing excess light generated around the backlight assembly 10, eliminating light pollution and avoiding highlight areas.

[0021] In order to paste the liquid crystal panel on the backlight assembly 10 , a transparent double-sided adhesive layer 30 is provided adjacent to the inner side of the light-shielding layer 20 on the upper surface of the optical film. Wherein, the double-sided adhesive layer 30 is OCA (Optically Clear Adhesive, solid transparent optical adhesive) or OCR (Optical Clear Resin, liquid transparent optica...

Embodiment 2

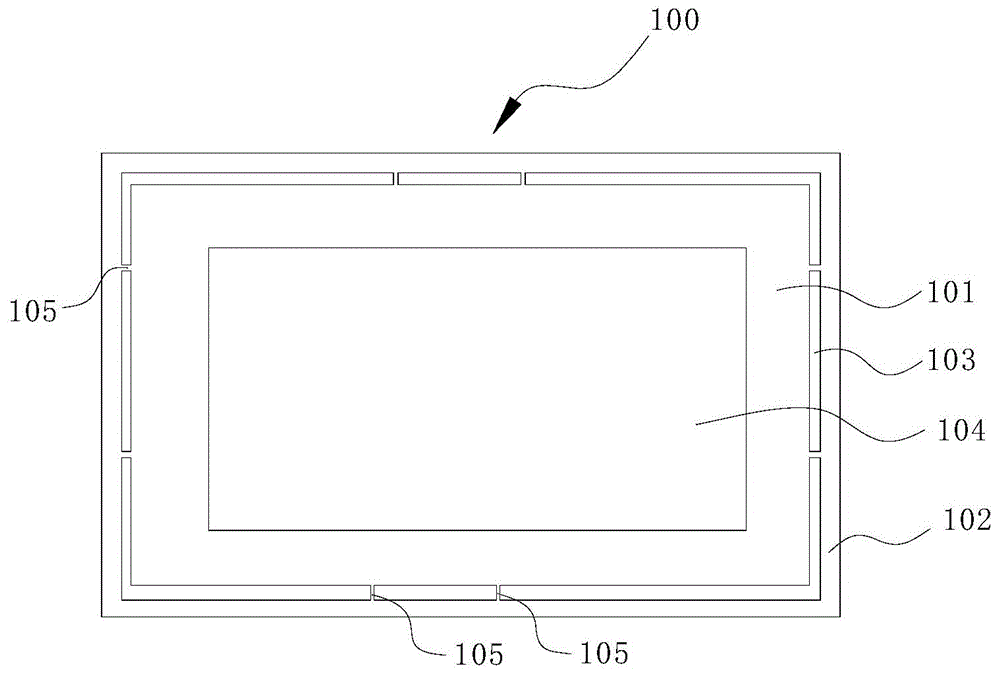

[0024] Such as image 3 In order to improve the spraying accuracy and spraying efficiency of the light-shielding layer 20, the present invention also provides a spraying fixture 100, including a rectangular first shutter 101 and a second shutter 102, the second shutter 102 is a frame structure, The external dimension of the second shutter 102 is larger than that of the backlight assembly 10, and the first shutter 101 is located in the second shutter 102, and the first shutter 101 and the second shutter 102 are connected by a plurality of connecting bars 105 to form a The interval groove 103 between the plate 101 and the second shutter 102 can be sprayed through the interval groove 103 .

[0025] A plurality of connecting bars 105 are arranged at intervals between the first shroud 101 and the second shroud 102 for connecting the two, and divide the interval groove 103 into a plurality of isolated groove areas.

[0026] At the same time, in order to reduce the manufacturing cos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com