Method and device for measuring plate cut of belt material on line

A strip and plate technology, applied in the field of measurement, to achieve the effect of low cost, high measurement accuracy and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

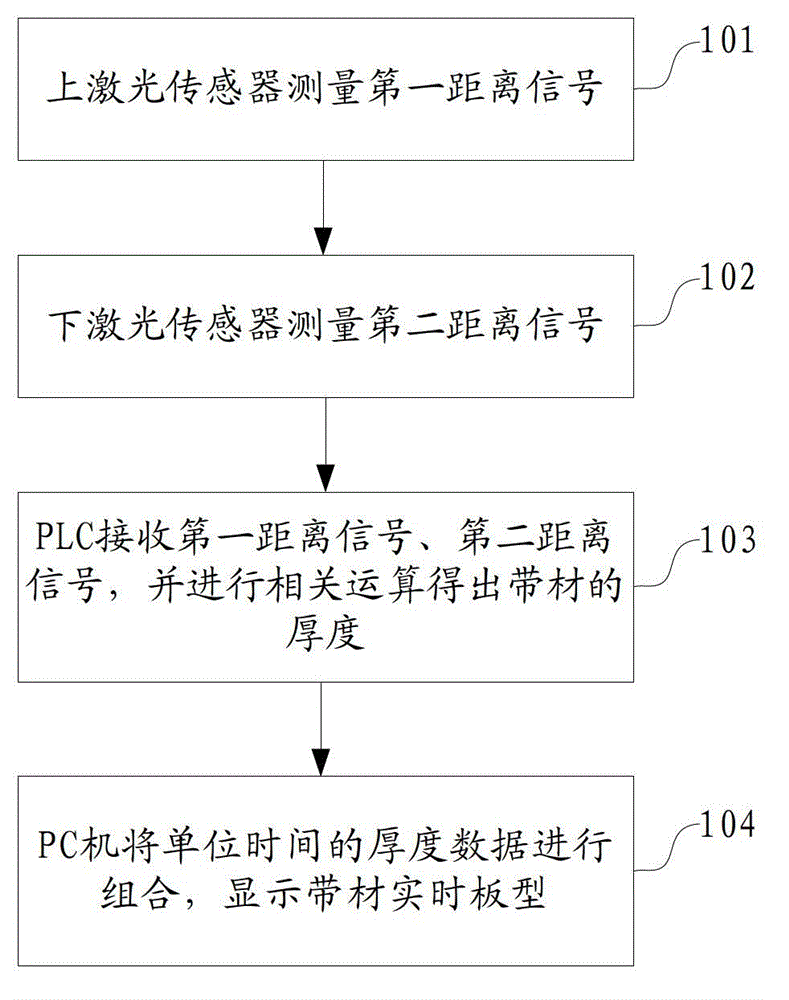

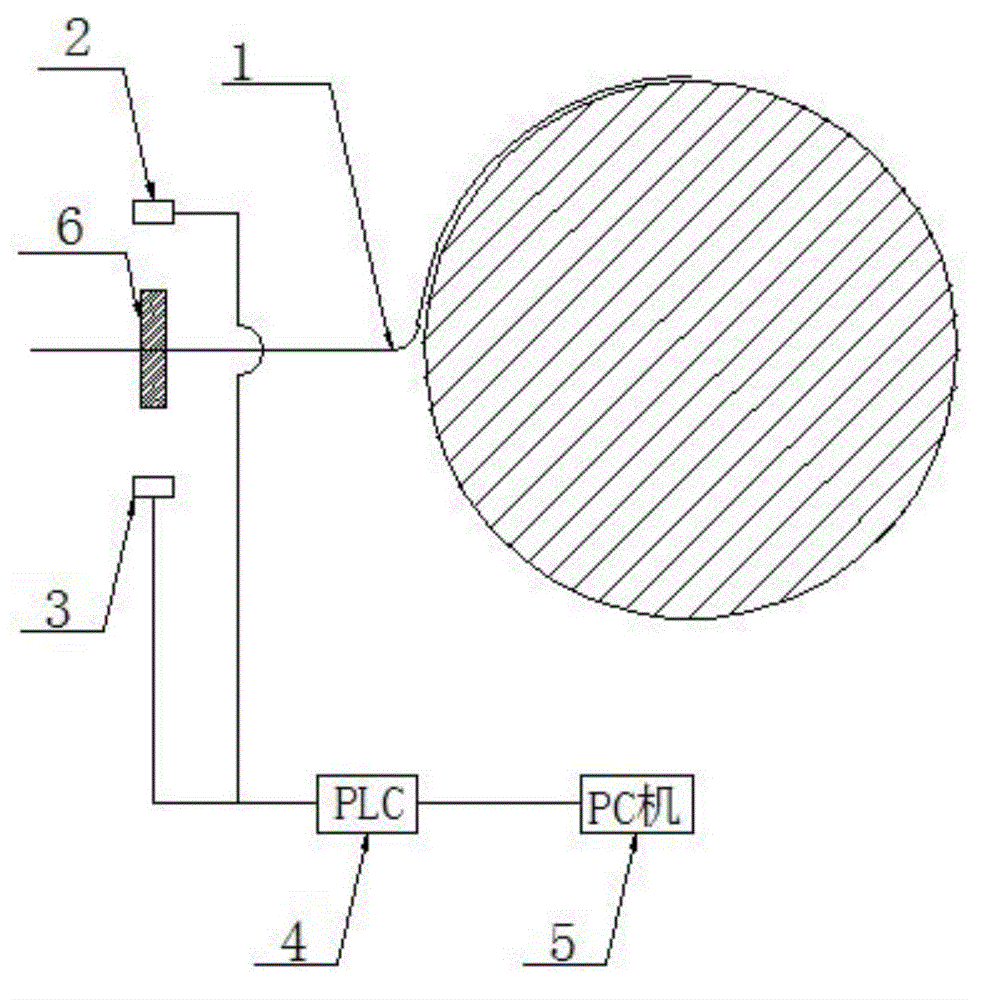

Method used

Image

Examples

example 1

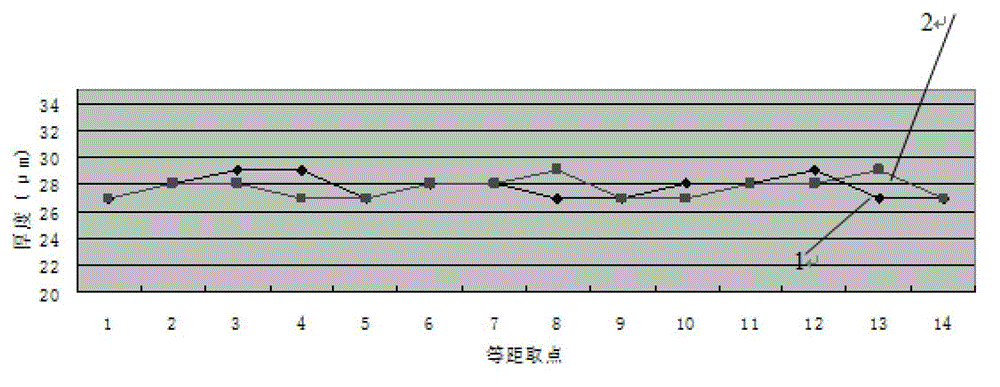

[0027] Example 1: The thickness of the test strip is between 27-29μm. Such as image 3 As shown, curve 1 is the measured data of the present invention, and curve 2 is the actual measured data. The strip thickness measured by the present invention is consistent with the actually measured strip thickness.

[0028] It should be noted that the characterization of strip properties is determined by physical parameters and magnetic performance parameters. Different characterizations of the same object will have specific and interrelated characterizations when they approach the true value. The invention obtains the real-time profile of the strip by combining the profile lines at a unit time point into a profile surface. Through the real-time monitoring of the shape of the strip, combined with the analysis of the magnetic performance results, the physical parameters affecting the magnetic properties of the strip are obtained, and finally the annealing time before the strip leaves the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com