Process and device for producing high-oxygen sponge titanium

A high-oxygen sponge and process technology, applied in the field of non-ferrous metal smelting, can solve problems such as not a complete solution, uneven chemical composition, segregation of titanium ingot composition, etc., to improve uniformity and quality stability, and avoid composition segregation and localization. Defects, the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

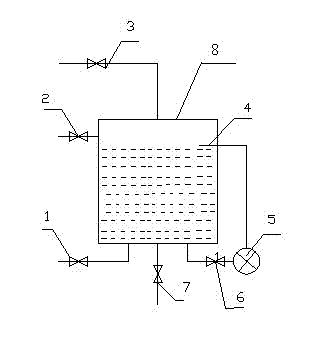

Image

Examples

Embodiment 1

[0023] Embodiment 1: Taking a five-ton reduction furnace as an example, a total of 20 tons of titanium tetrachloride needs to be added. After adding 2 tons of titanium tetrachloride, add 1.8kg of high-purity oxygen to the titanium tetrachloride high-level tank, and supplement argon to ensure the pressure in the high-level tank. Keep it at 0.03~0.1MPa, and use the gas-liquid mixing pump to mix the gas and liquid in the high level tank. Ensure that titanium tetrachloride fully absorbs oxygen. Titanium tetrachloride is fed into the reactor through the feed pipe, and magnesium in the reactor reduces titanium tetrachloride to obtain titanium sponge.

[0024] The pressure in the reactor is kept between 0.02-0.05MPa, the temperature of the melt in the reactor is controlled between 720-840°C, and argon is added to maintain the pressure of the high-level tank when the pressure of the high-level tank is lower than 0.03MPa.

[0025] The main indicators for finally obtaining titanium sp...

Embodiment 2

[0026] Example 2: Taking a five-ton reduction furnace as an example, a total of 20 tons of titanium tetrachloride needs to be added. After adding 2 tons of titanium tetrachloride, add 2.35kg of high-purity oxygen to the titanium tetrachloride head tank, and supplement argon to ensure the pressure in the head tank. Keep it at 0.03~0.1MPa, and use the gas-liquid mixing pump to mix the gas and liquid in the high level tank. Ensure that titanium tetrachloride fully absorbs oxygen. Titanium tetrachloride is fed into the reactor through the feed pipe, and magnesium in the reactor reduces titanium tetrachloride to obtain titanium sponge.

[0027] The pressure in the reactor is kept between 0.02-0.05MPa, the temperature of the melt in the reactor is controlled between 720-840°C, and argon is added to maintain the pressure of the high-level tank when the pressure of the high-level tank is lower than 0.03MPa.

[0028] The main indicators for finally obtaining titanium sponge are: oxy...

Embodiment 3

[0029] Example 3: Taking a five-ton reduction furnace as an example, a total of 20 tons of titanium tetrachloride needs to be added. After adding 2 tons of titanium tetrachloride, add 6.2kg of high-purity carbon dioxide to the high-level tank of titanium tetrachloride, and supplement argon to ensure the pressure in the high-level tank. Keep it at 0.03~0.1MPa, and use the gas-liquid mixing pump to mix the gas and liquid in the high level tank. Ensure that titanium tetrachloride fully absorbs oxygen. Titanium tetrachloride is fed into the reactor through the feed pipe, and magnesium in the reactor reduces titanium tetrachloride to obtain titanium sponge.

[0030] The pressure in the reactor is kept between 0.02-0.05MPa, the temperature of the melt in the reactor is controlled between 720-840°C, and argon is added to maintain the pressure of the high-level tank when the pressure of the high-level tank is lower than 0.03MPa.

[0031] The main indicators for finally obtaining ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com