Process for producing catalyst patricle diameter control type carbon nanostructure production, production apparatus therefor, and carbon nanostructure

A carbon nanostructure and manufacturing device technology, applied in the direction of nanocarbon, carbon nanotubes, chemical instruments and methods, etc., can solve problems such as increased production cost, reduced yield of carbon nanostructures, and unstable yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

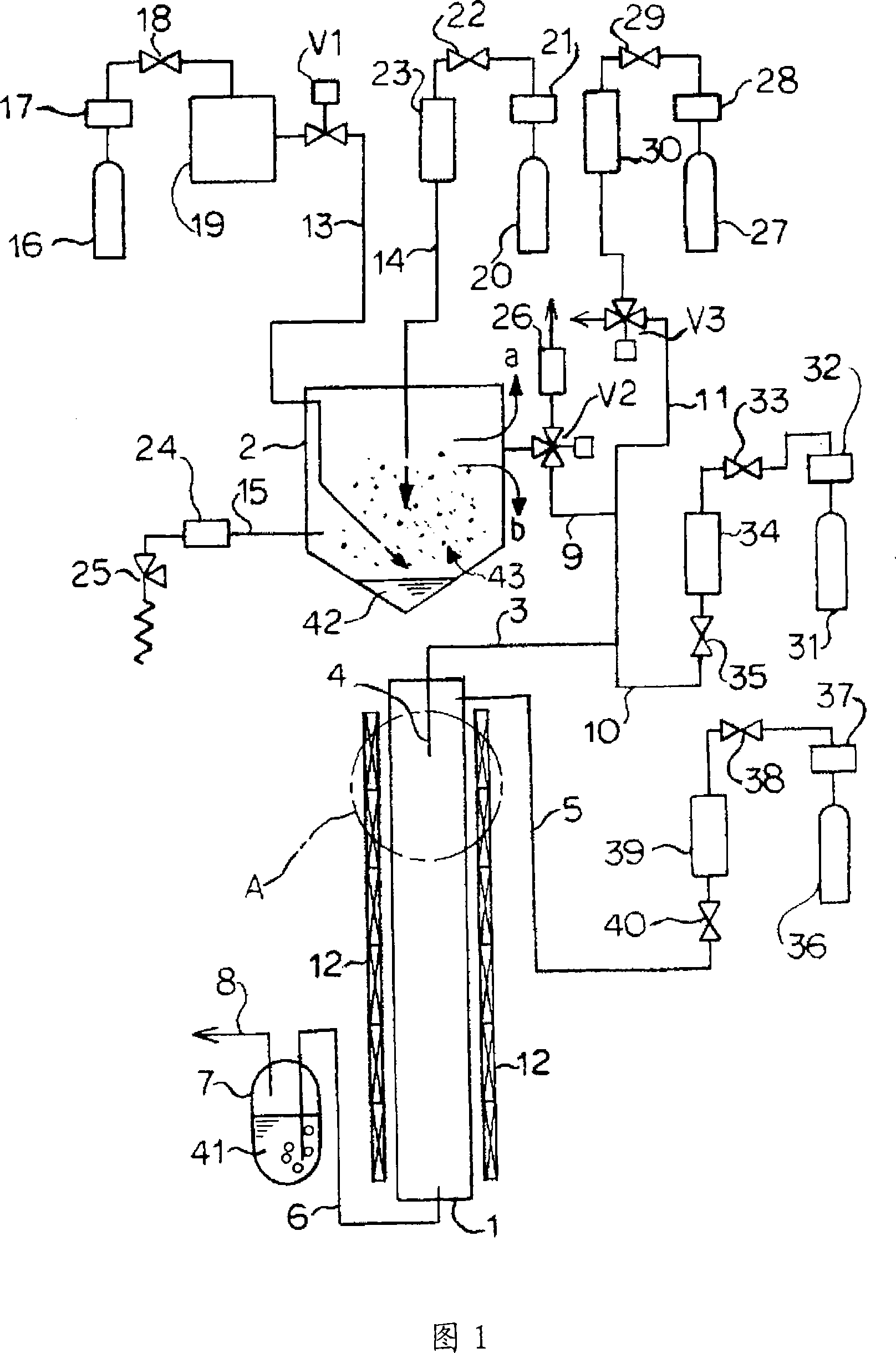

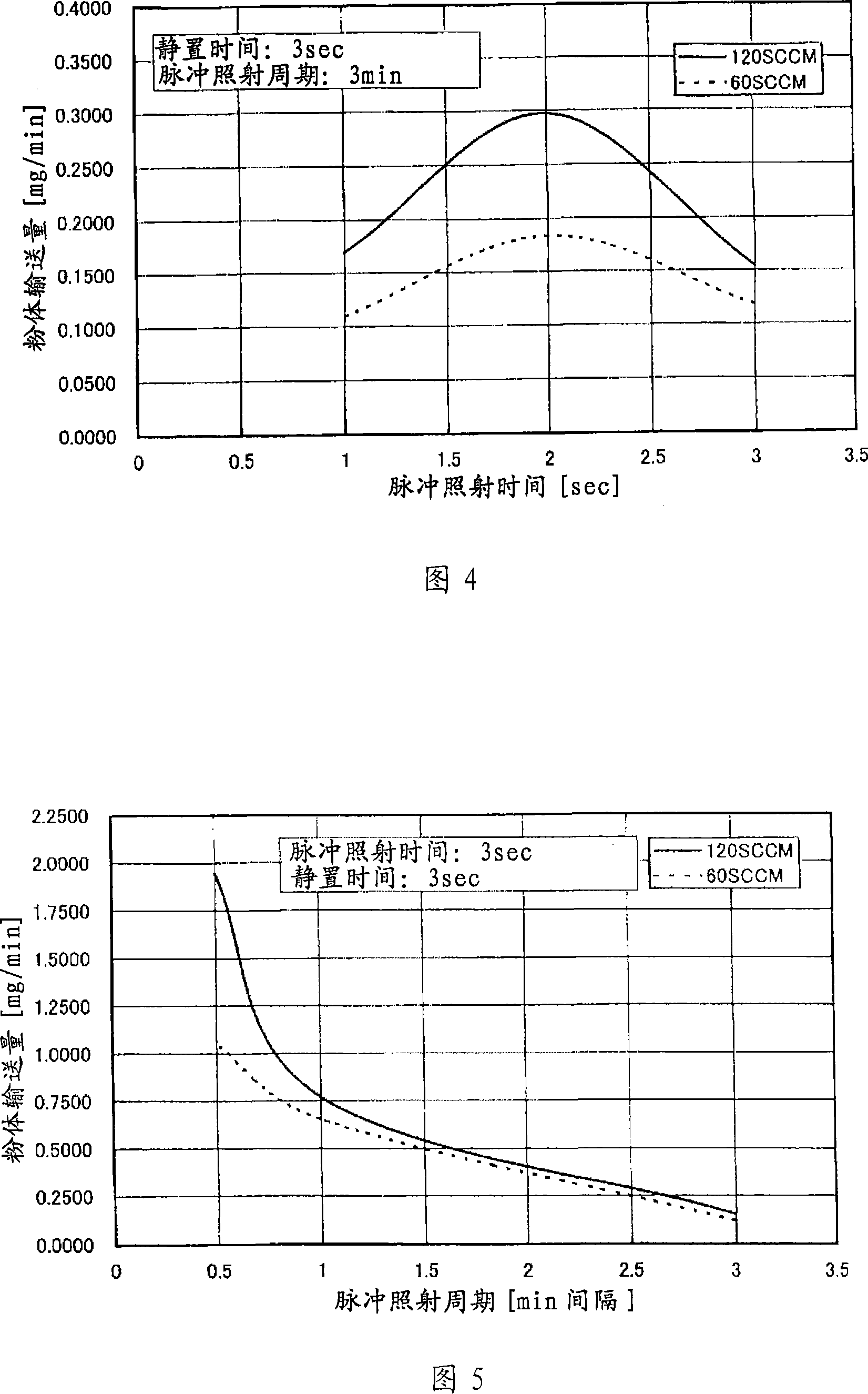

[0155] First, catalyst floatation was carried out under pulse gas generation conditions in which the electromagnetic switching valve V1 was intermittently opened and closed at 600 times / min to generate a high-pressure pulse gas of 0.3 MPa. The high-pressure pulse gas is sprayed from the front end of the high-pressure pulse gas introduction pipe 13, and the irradiation time on the catalyst in the catalyst storage tank 2 is set to 1, 2, and 3 seconds. After flotation, stop the subsequent high-pressure pulse gas irradiation, and let stand for 3 seconds. Under the above conditions of catalyst floating and standing still, when the flow rate of the carrier gas supplied from the helium cylinder 20 was 60, 120 SCCM, the delivery amount of the floating catalyst delivered to the reaction furnace 1 was measured. The measurement results are shown in Figure 4. The catalyst used is Fe-In-Sn-O.

[0156] It can be seen from the measurement results of the catalyst powder delivery amount and ...

experiment example 2

[0158] Under the condition that the pulse irradiation time is set to 3 seconds, the high-pressure pulse gas irradiation is performed and then left to stand for 3 seconds. After standing still, the actual cycle, in other words, the delivery time interval, that is, the pulse irradiation cycle time, is changed to 0.5, 1, 3 minutes (min). Other conditions are all the same as in Experimental Example 1. When the flow rate of the carrier gas of helium is set to 60, 120 SCCM, the delivery amount of the floating catalyst delivered to the reaction furnace 1 is measured, and the measurement results are shown in FIG. 5 .

[0159] It can be seen from the measurement results of catalyst powder delivery amount and pulse irradiation cycle time in Fig. 5 that the pulse irradiation cycle time of 3 minutes is appropriate.

experiment example 3

[0161] The pulse irradiation time is set to 3 seconds, and the standing time after the high-pressure pulse gas irradiation is changed to 0.5, 3, and 10 seconds. Other conditions are the same as in Experimental Example 1 and 2. The flow rate of the helium carrier gas is set to 60, At 120SCCM. The transport amount of the floating catalyst transported to the reaction furnace 1 was measured, and the measurement results are shown in FIG. 6 .

[0162] It can be seen from the measurement results of the catalyst powder delivery amount and the resting time in Fig. 6 that the resting time of 10 seconds is too long to promote the sedimentation of the catalyst, so the resting time of 3 seconds is appropriate.

[0163] Moreover, considering the use of high-pressure pulse gas, a safety valve 25 is installed at the bottom of the catalyst storage tank 2 through a gas discharge pipe 15 and a filter 24 . In addition, in the above-mentioned reaction furnace 1, a thermal decomposition method is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com