Auto-injector

An auto-injector, trigger technology, applied in auto-injectors, syringes, hypodermic instruments, etc., can solve problems such as button inconvenience, button/plunger extension, hand tremor/jitter, etc., to achieve low parts count, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

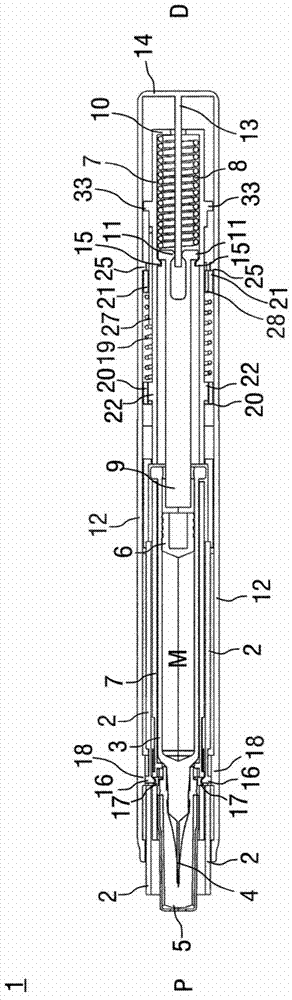

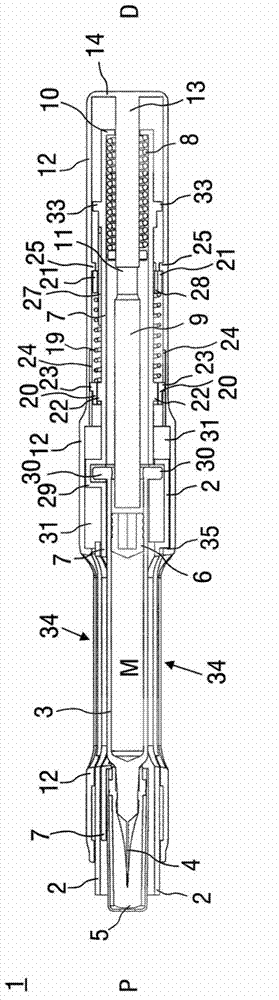

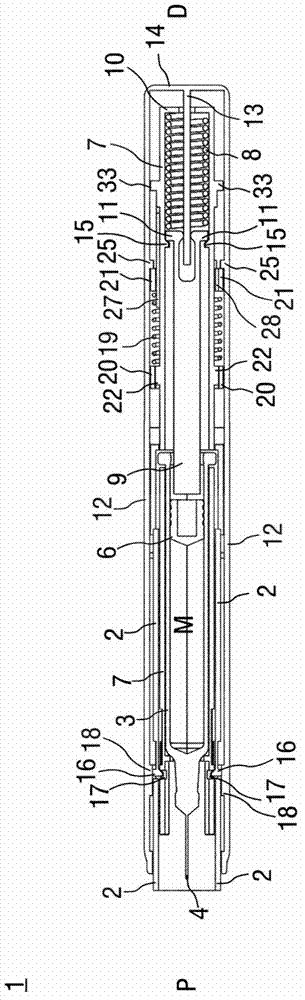

[0057] FIG. 1 shows two longitudinal sections of an autoinjector 1 in different sections rotated by approximately 90 degrees relative to each other, wherein the autoinjector 1 is in an initial state before starting an injection. The autoinjector 1 includes a chassis 2 . In the proximal part of the autoinjector 1 is arranged a barrel 3 with a hollow injection needle 4 , for example a Hypak barrel. A protective needle shield 5 is attached to the needle 4 when the autoinjector 1 or barrel 3 is assembled. A bung 6 is provided for sealing the barrel 3 distally and for moving liquid medicament M through the hollow needle 4 . The barrel 3 is held in a tubular holder 7 and is supported therein at its proximal end. The bracket 7 is slidably arranged in the chassis 2 .

[0058] A drive spring 8 in the shape of a compression spring is arranged in the distal part of the bracket 7 . The plunger 9 is used to feed forward the force of the drive spring 8 to the bung 6 .

[0059] The driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com