Method for manufacturing sealed cell

A manufacturing method and a technology of sealing batteries, which are applied to battery pack parts, circuits, electrical components, etc., can solve the problems of difficulty in thinning the battery and increasing the front and rear width of insulating parts, so as to prevent misalignment and reduce labor and time , The effect of reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

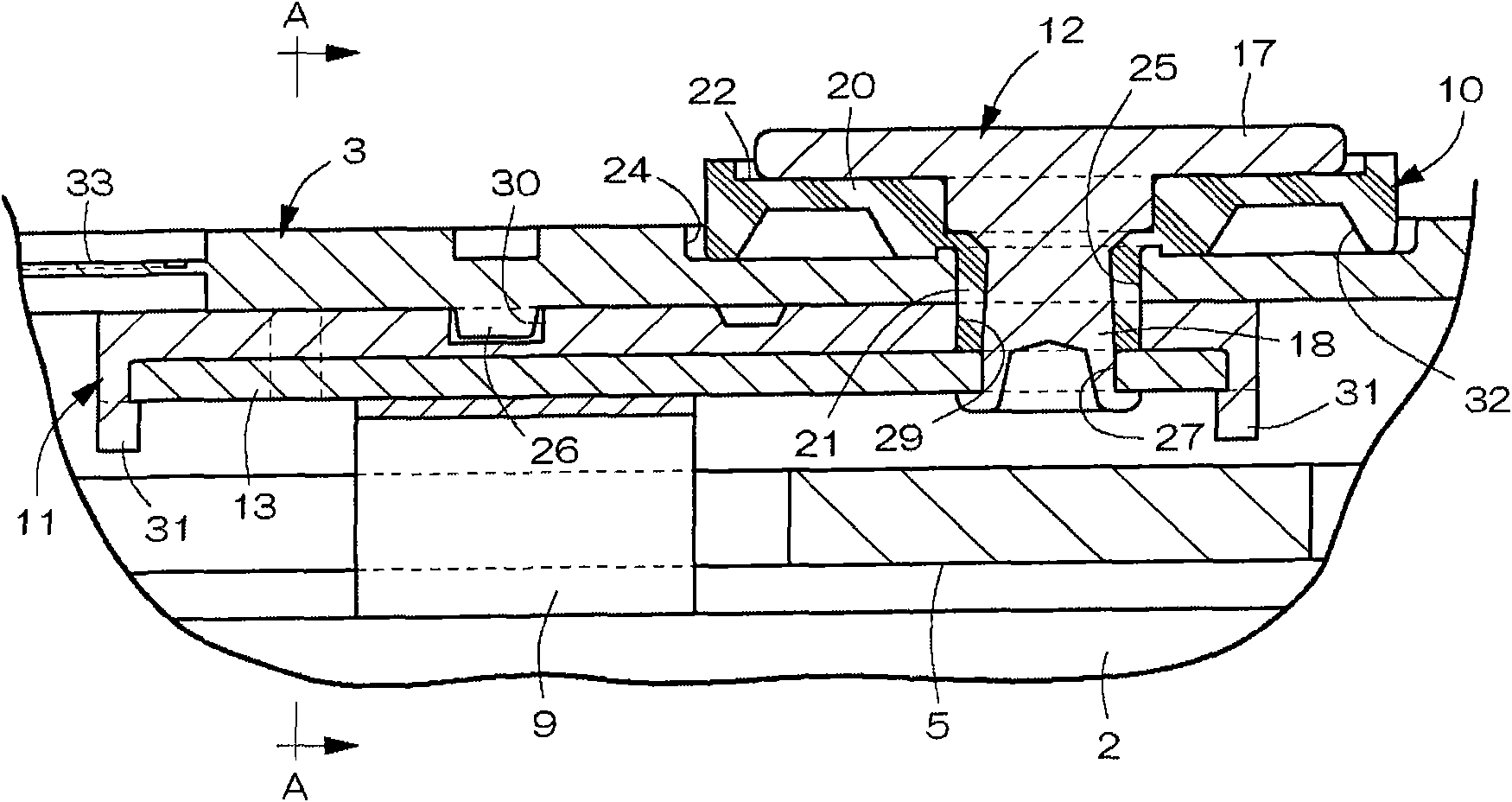

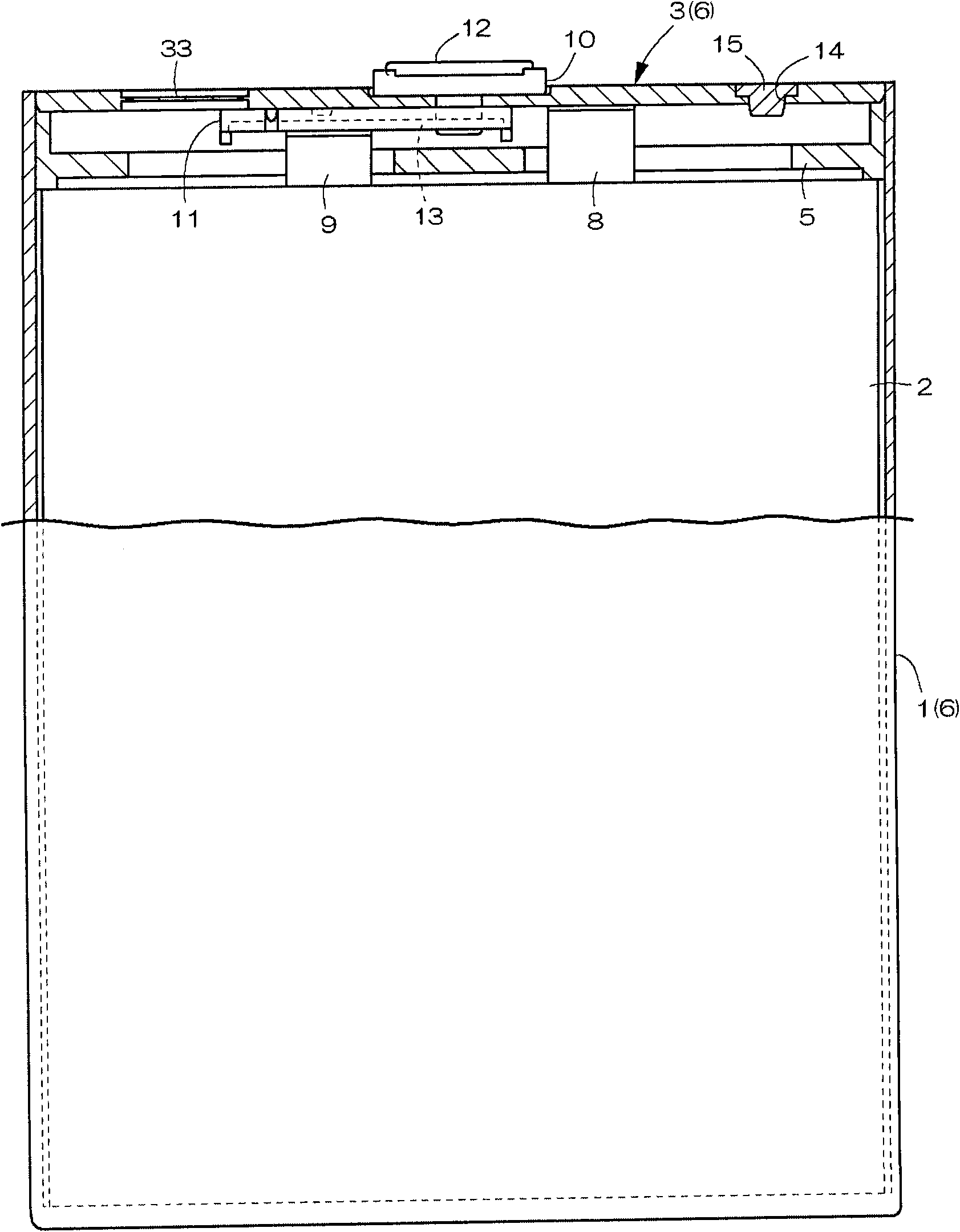

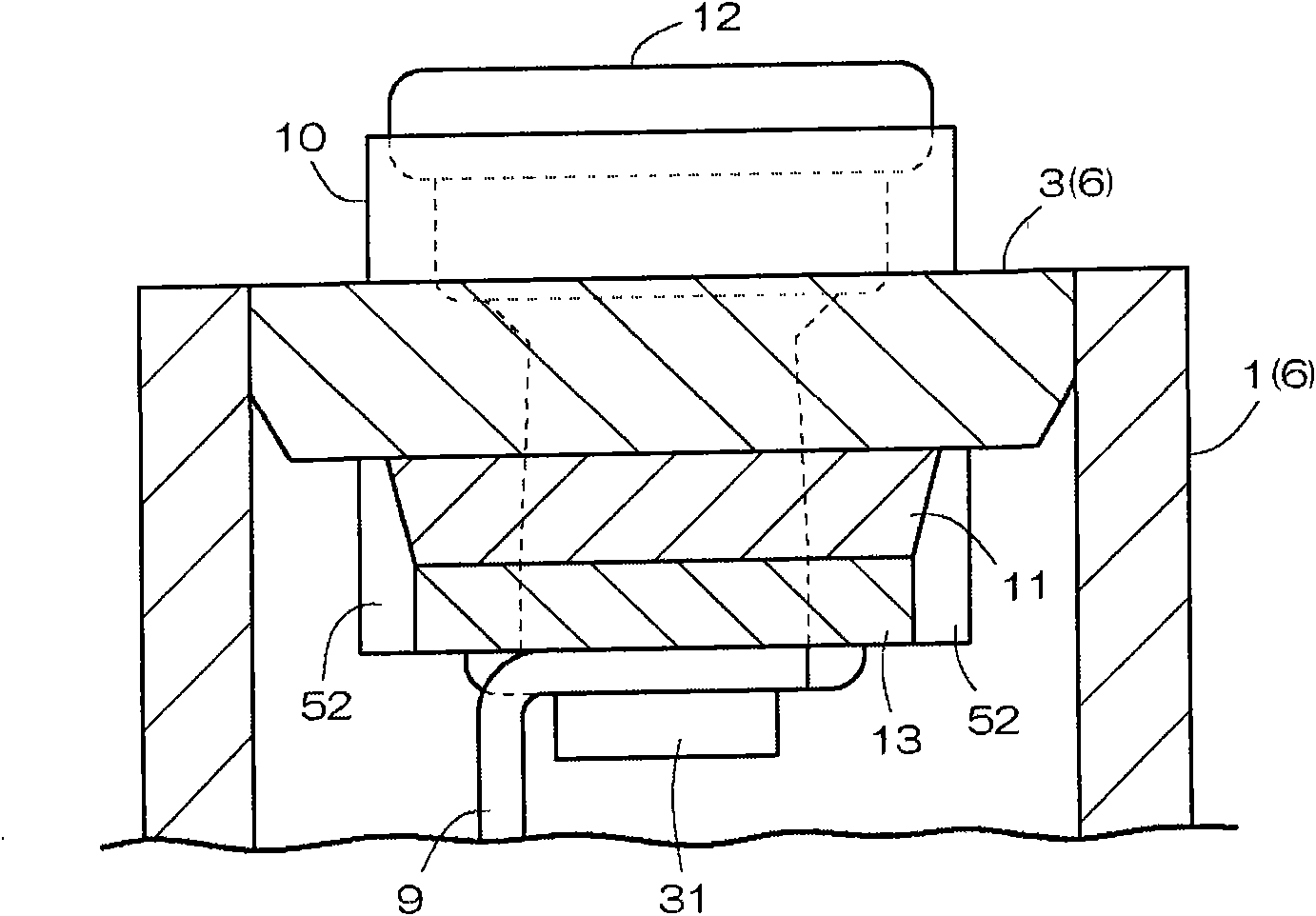

[0033] Related to the sealed battery of the present invention such as figure 2 As shown, it includes: a bottomed cylindrical battery can 1 with left and right horizontally long openings on the top; an electrode body 2 and a non-aqueous electrolyte stored in the battery can 1; a laterally long cover 3 ; and an insulator 5 arranged inside the cover 3 . The left and right width of the battery can 1 is 34 mm, the vertical height is 46 mm, and the front and rear thickness is 4 mm. A battery case 6 is formed by the battery can 1 and the cover 3 .

[0034] The electrode body 2 is produced by, for example, helically winding a strip-shaped positive electrode and a strip-shaped negative electrode with a strip-shaped separator inserted therebetween, and is formed into a flat shape in the wound state. The positive electrode is to form a positive electrode active material layer containing a positive electrode active material such as lithium cobaltate on both the front surface and the bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com