Lens installation mechanism, and installation method, as well as method for adjusting inclination and focusing plane of sensor

A technology of installation mechanism and installation method, which is applied in the direction of installation, camera body, instrument, etc., and can solve the problems of uneven thickness of solder or adhesive, not being truly parallel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

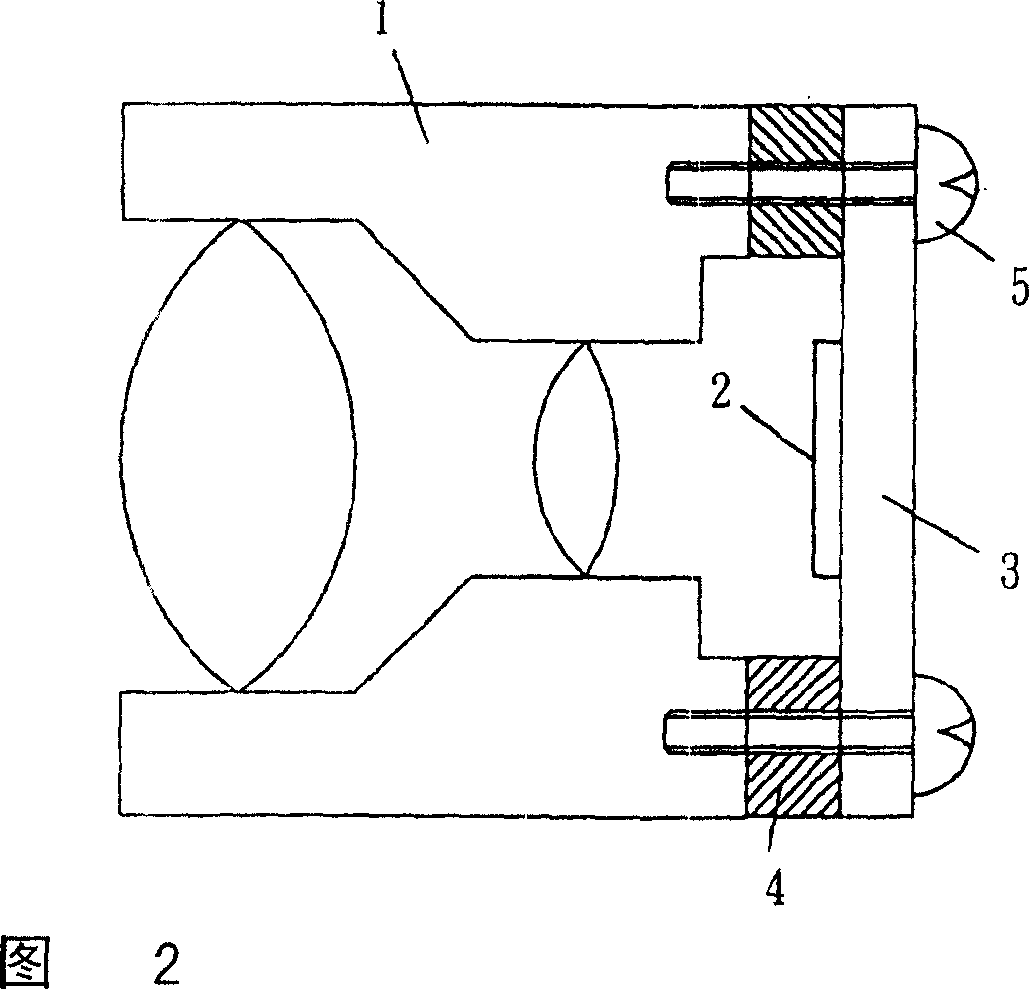

[0024] One embodiment of the present invention is conceptually shown in FIG. 2 . 2 is a cross-sectional view of a lens mounting mechanism using an elastic material according to an embodiment of the present invention.

[0025] In FIG. 2 , the sensor 2 is fixed on the substrate 3 by welding or bonding. A circle of rubber 4 is clamped between the lens 1 and the base plate 3, and is tightened and fixed by screws 5 passing through. The contact surface between the lens 1 and the rubber 4 and the contact surface between the rubber 4 and the substrate 3 are in a light-tight and always in close contact state.

[0026] Next, in the lens mounting mechanism using an elastic material of the present invention, the method of adjusting the sensor tilt and the method of adjusting the focus plane will be described using examples.

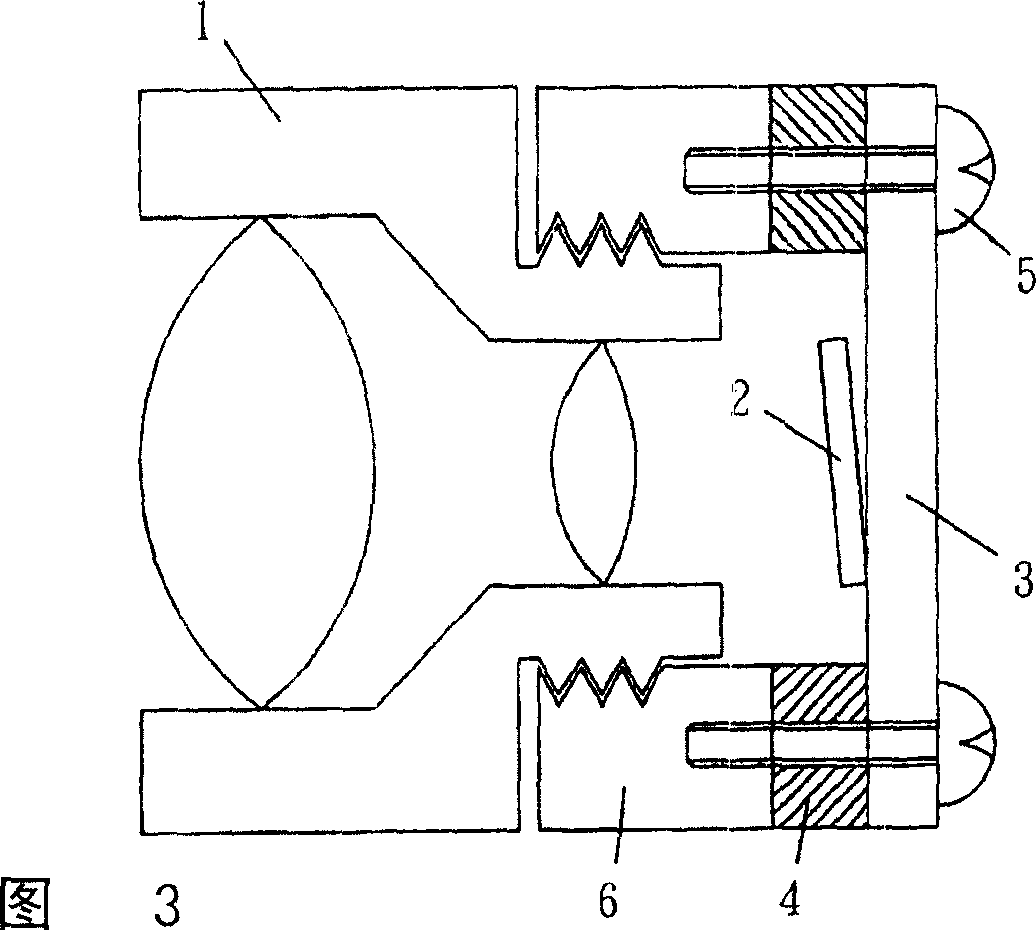

[0027] 3 to 7 are adjustment diagrams of sensor tilt and focus plane according to an embodiment of the present invention.

[0028] In FIG. 3 , the lens holder 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com