Conductive layer transfer material and touch panel

A technology for transfer printing materials and conductive layers, applied to conductive materials, conductive materials, conductive layers on insulating carriers, etc., can solve problems such as inability to conform to conductive layers, use restrictions, and insulation of glass substrates, etc., to improve uniformity of transfer printing Good adhesion and unevenness, fewer parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0286] Hereinafter, examples of the present invention will be described, but the present invention is not limited by these examples.

[0287] In the following examples, the average thickness of the substrate, the average thickness of the conductive layer, and the average thickness of the buffer layer were measured as follows.

[0288]

[0289] It can be measured by the following method: SEM observation is performed after exposing the cross-section of the material by cutting with a microtome, or TEM observation is performed on a slice made by a microtome after embedding with epoxy resin. The average thickness of these base materials and each layer is the average value measured at 10 places.

Synthetic example 1

[0291]

[0292]Using 7.79g (grams) of methacrylic acid (MAA) and 37.21g of benzyl methacrylate (BzMA) as the monomer components constituting the copolymer, and 0.5g of azobisisobutyronitrile (AIBN) as the radical polymerization initiator Agent, these compounds are polymerized in 55.00 g of solvent propylene glycol monomethyl ether acetate (PGMEA), thereby obtaining the PGMEA solution (solid content concentration) of the binder (A-1) represented by the following formula: 45% by mass). In addition, the polymerization temperature is adjusted to a temperature of 60°C to 100°C.

[0293] The weight average molecular weight (Mw) of the binder (A-1) was measured using gel permeation chromatography (GPC). As a result, the weight average molecular weight (Mw) in terms of polystyrene was 30,000, and the molecular weight distribution (Mw / Mn) was 2.21.

[0294] [Chem 3]

[0295]

[0296] (modulation example 1)

[0297] -Preparation of silver nanowire aqueous dispersion-

[0298]...

example 1

[0321]

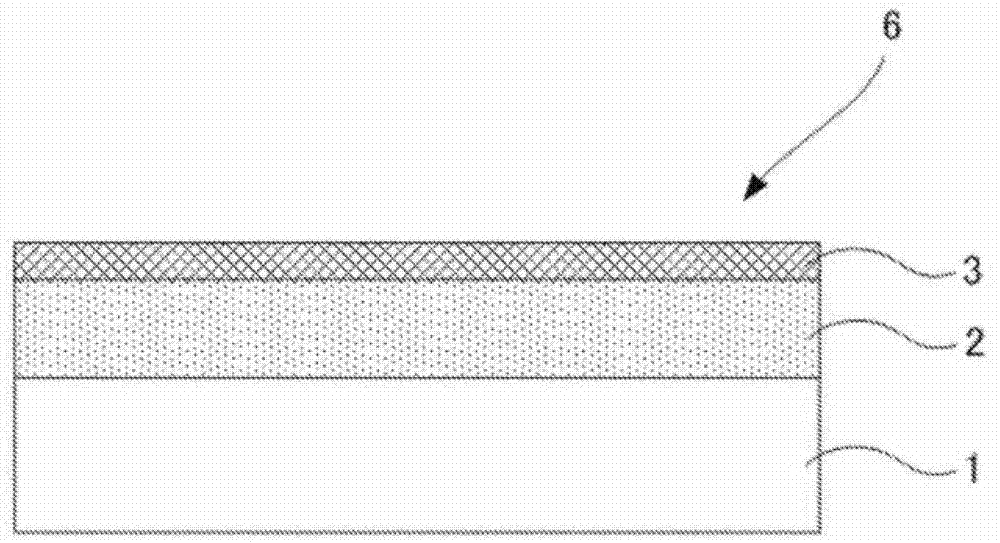

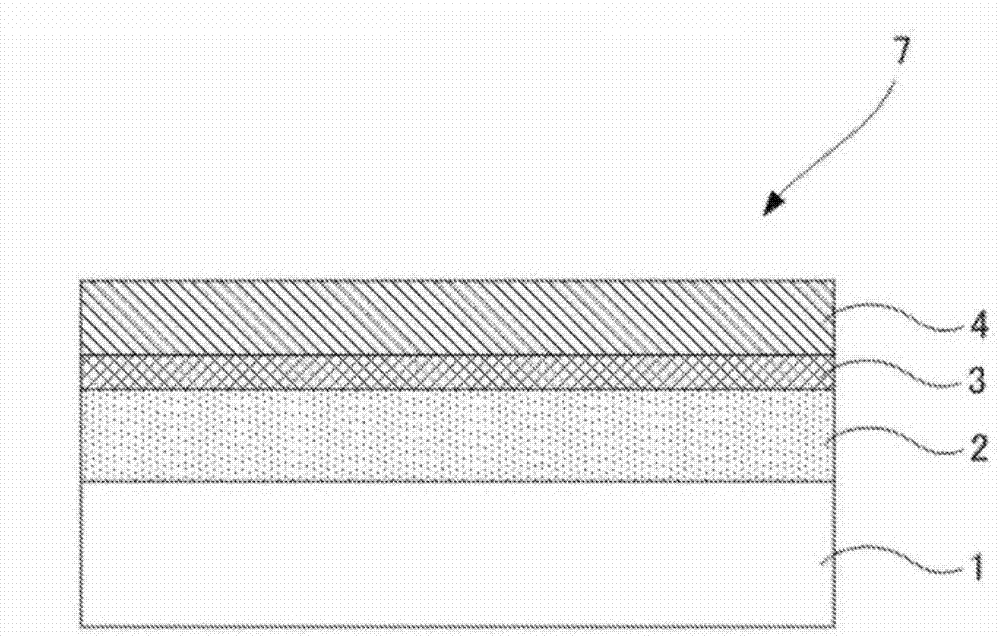

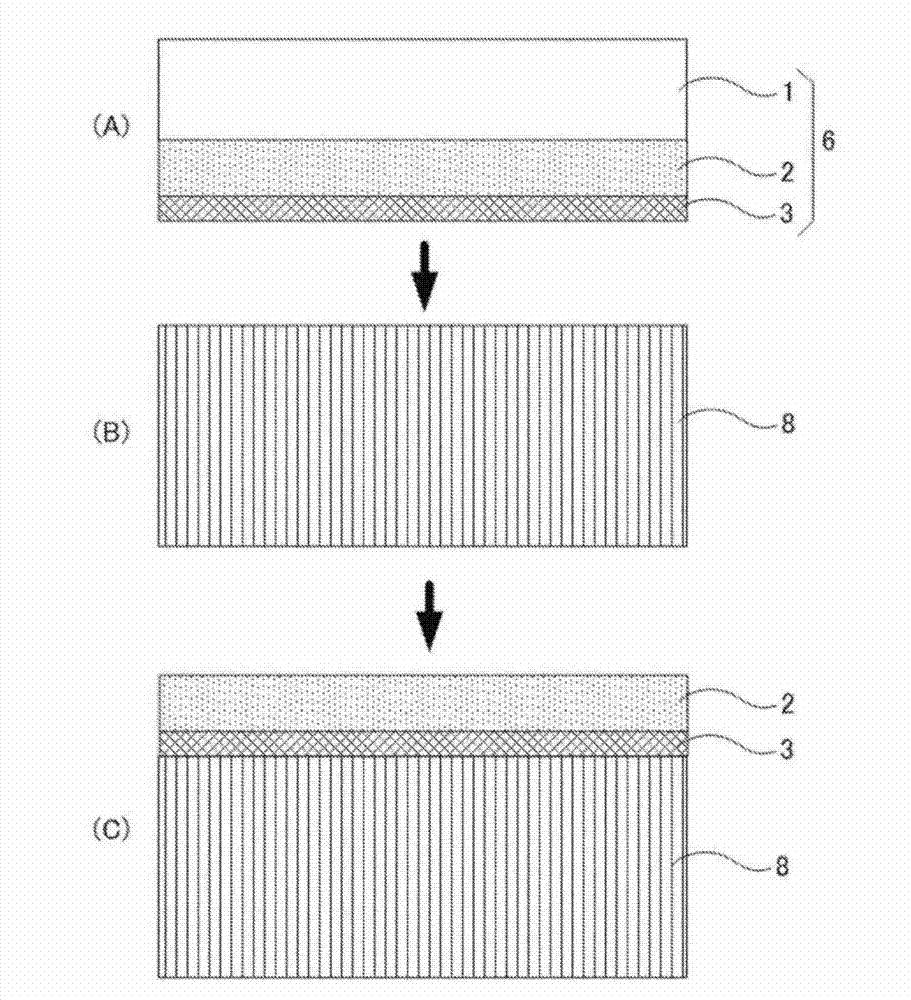

[0322] "The Formation of the Buffer Layer"

[0323] On a polyethylene terephthalate (PET) film having an average thickness of 30 μm as a substrate, a buffer layer coating solution having the following composition was applied and dried to form a buffer layer with an average thickness of 10 μm.

[0324] -Composition of coating liquid for buffer layer-

[0325] Methyl methacrylate / 2-ethylhexyl acrylate / benzyl methacrylate / methacrylic acid copolymer (copolymerization composition ratio (molar ratio)=55 / 30 / 10 / 5, weight average molecular weight=100,000 , glass transition temperature (Tg) = 70°C) 6.0 parts by mass

[0326] ・Styrene / acrylic acid copolymer (copolymer composition ratio (molar ratio) = 65 / 35, weight average molecular weight = 10,000, glass transition temperature (Tg) = 100° C.) 14.0 parts by mass

[0327] · BPE-500 (manufactured by Shin-Nakamura Chemical Co., Ltd.) · · · 9.0 parts by mass

[0328] · Megafac F-780-F (manufactured by Dainippon Ink Chemical Ind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com