Natural gas filter

A filter and natural gas technology, applied in the direction of dispersed particle filtration, chemical instruments and methods, pipes/pipe joints/fittings, etc., can solve the problems of costing a lot of manpower and financial resources, wasting manpower, material resources, financial resources, and multi-person operations. Achieve the effects of saving replacement costs, saving costs, and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Through the applicant's description of the embodiments, it will be more helpful to understand the present invention, and make the positive effects of the present invention more manifest, but the embodiments should not be regarded as limiting the solution of the present invention.

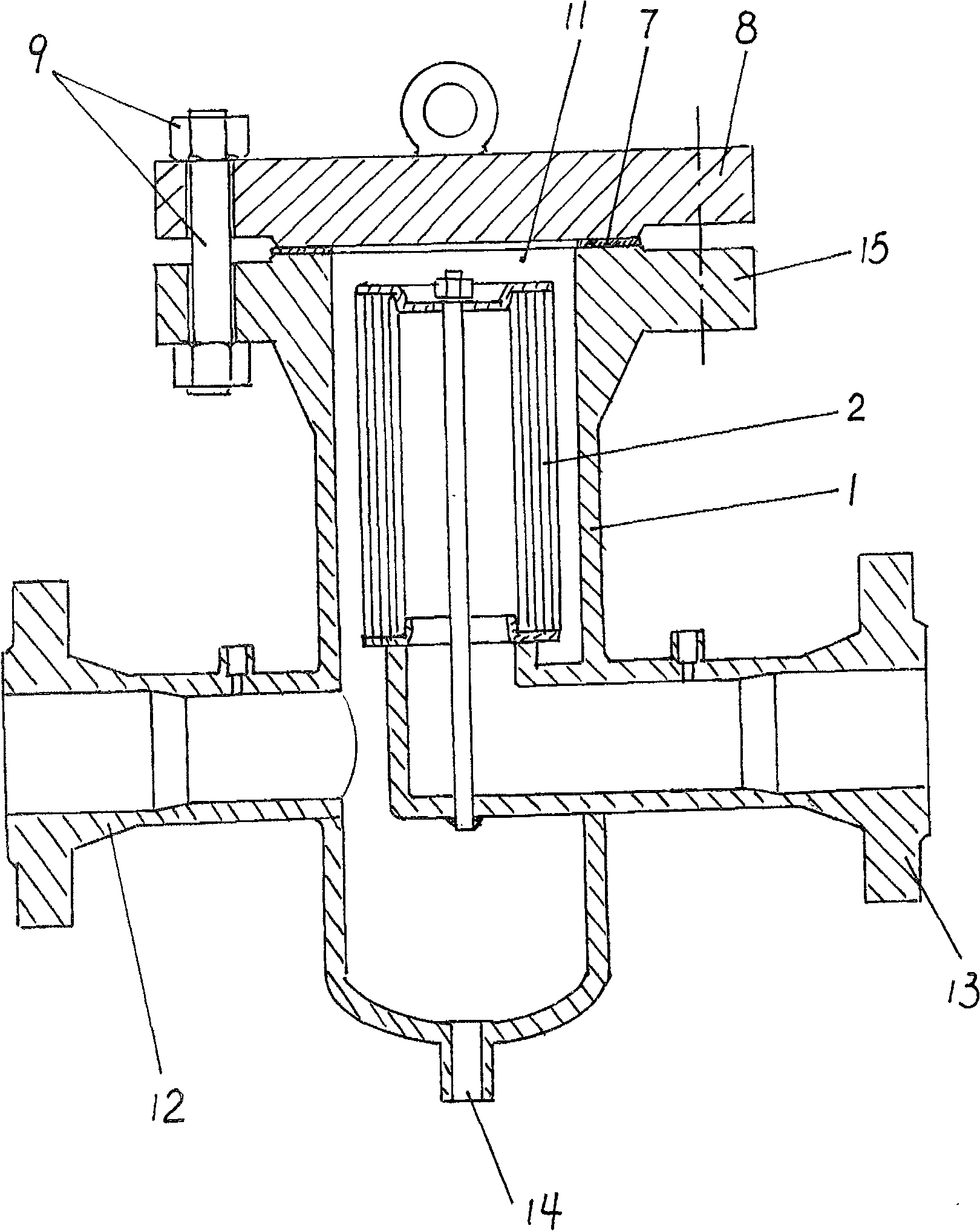

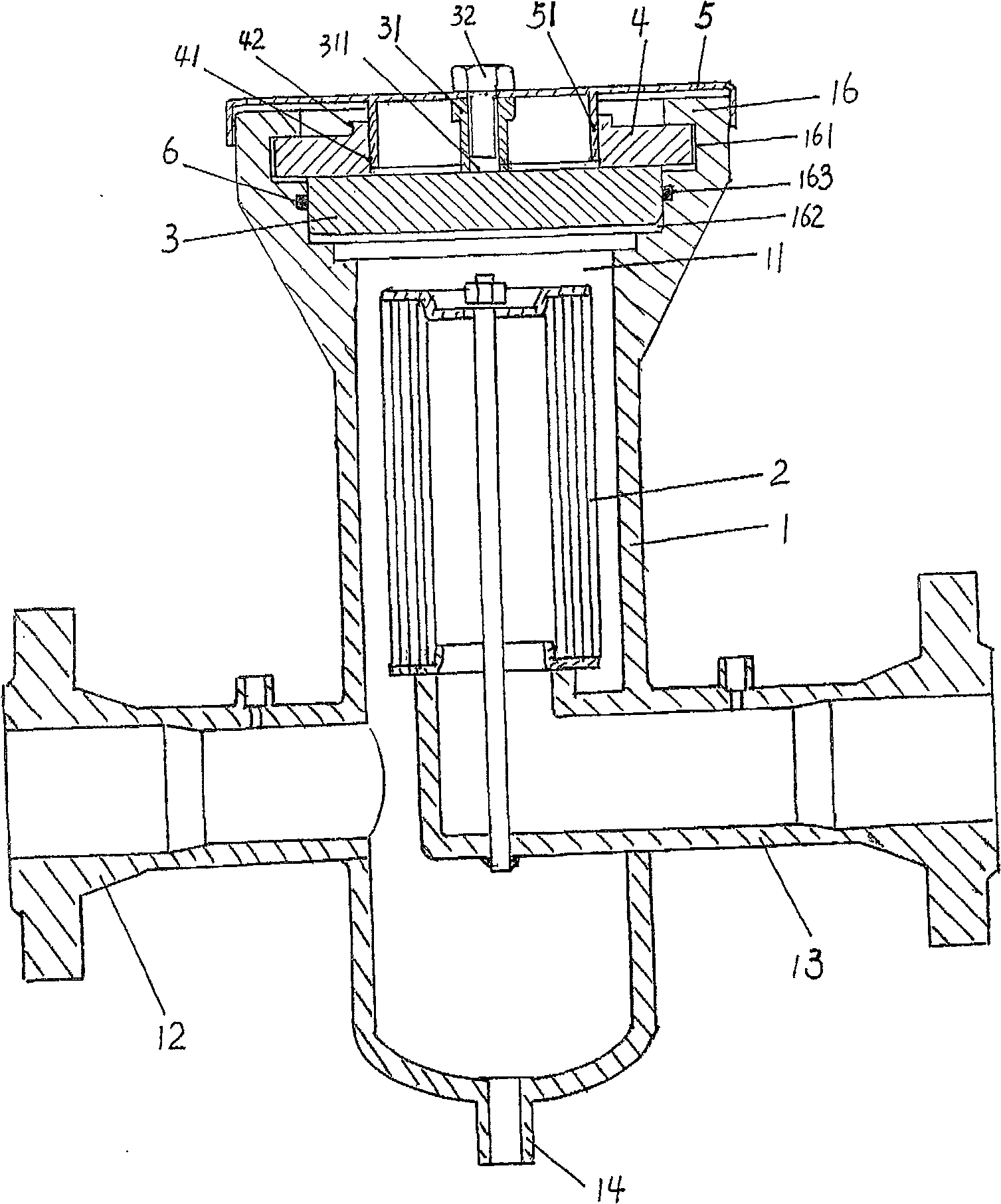

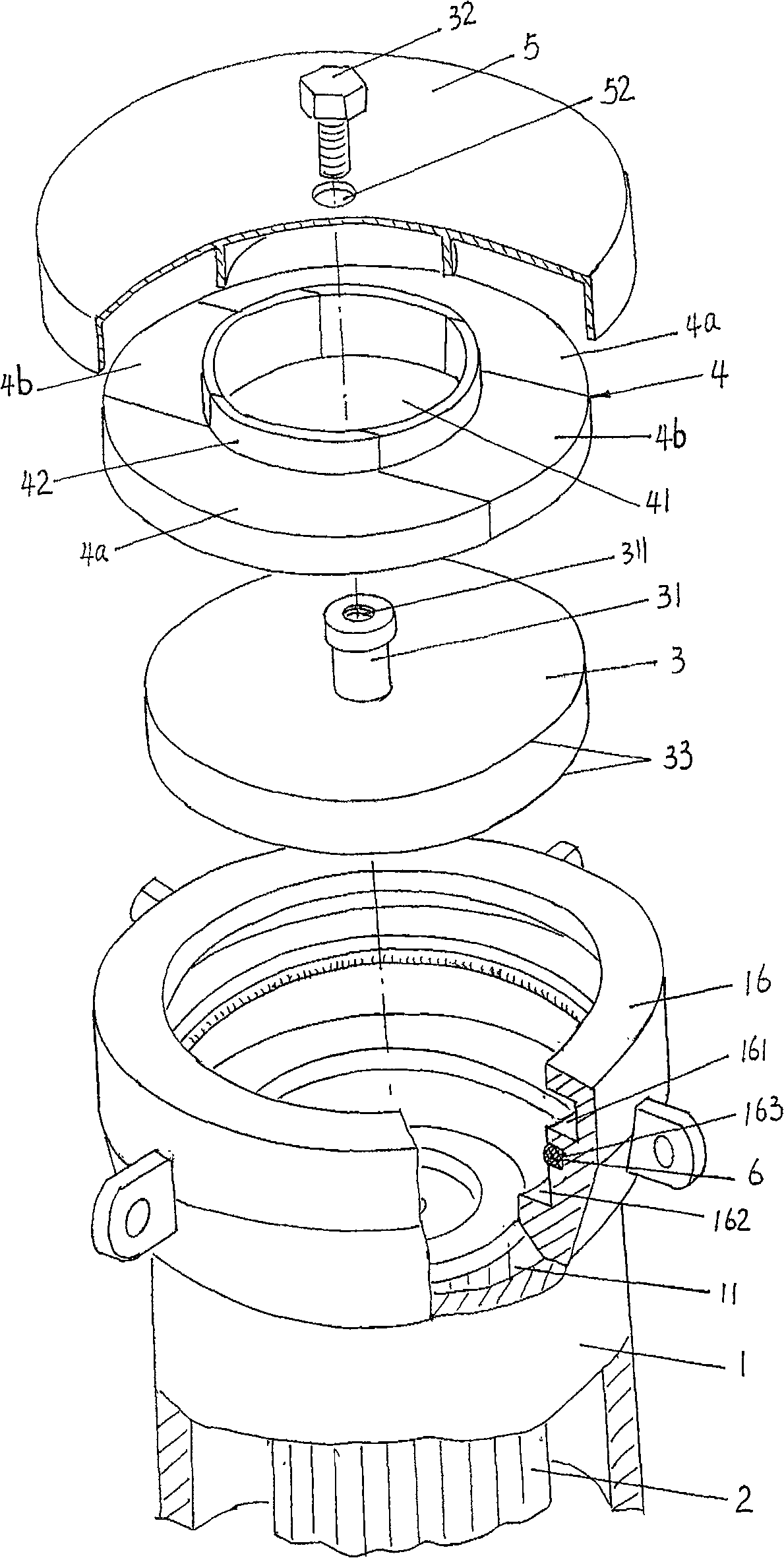

[0017] see figure 2 and combine image 3 , The natural gas filter of the present invention comprises cylinder body 1, filter core 2, and airtight mechanism, described cylinder body 1 is cylindrical shape, and its upper part has opening 11, and left side has raw material gas inlet 12, and right side has purified gas outlet 13 , The bottom has a sewage outlet 14, the raw material gas inlet 12, the purified gas outlet 13, and the sewage outlet 14 are connected with the cylinder cavity of the cylinder 1 respectively; the filter element 2 is placed in the cylinder cavity of the cylinder 1, and the front end of the filter element 2 Stretching to the position close to the opening 11, the rear end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com