Contained with repositionable slip-sheet to cover outlet

a slip-sheet and outlet technology, applied in the field of bulk bags, can solve the problems of affecting the transportation of bags, affecting the quality of bags,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

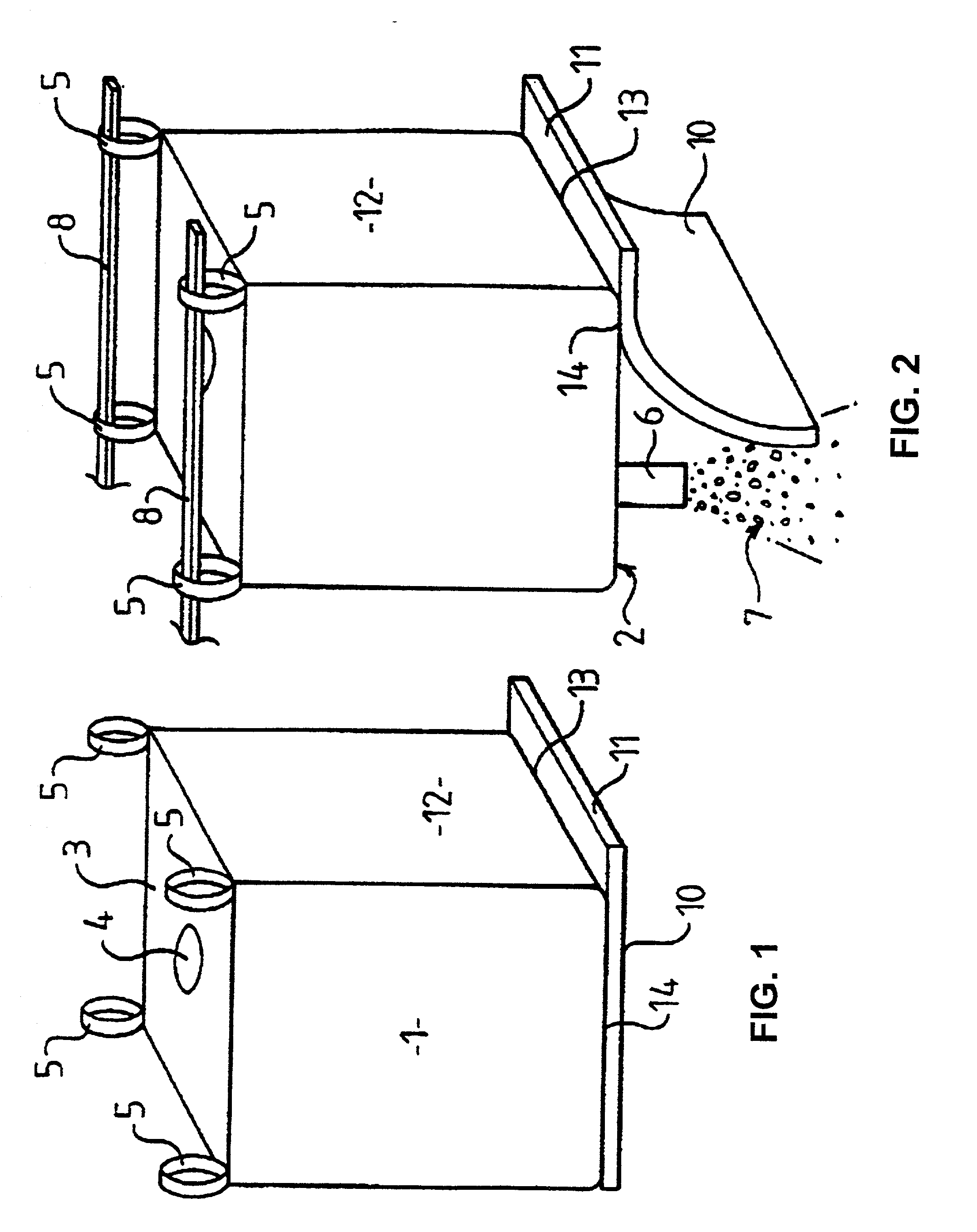

[0028] Initially, the bag or container 1 is sitting above the slip sheet 10 although connected thereto. Material to fill the bag is inserted therein, for example, through the aperture 4 in the upper surface 3.

[0029] The bulk bag 1 may then be transported or stored in the manner of bulk bags utilizing the advantages of the slip sheet, and, for example, the extension 11 allows the slip sheet to be pulled onto adapted fork-lift trucks or pulled into other places as desired.

[0030] When it is desired to empty the bag, and the bag 1 has an outlet, the bag is lifted, for example by being suspended by the loops 5, and the weight of the cover 10 will cause the cover to fold away from the outlet and the chute 6. The material 7 contained within the bulk bag will then be discharged as required. The empty bag can then be dropped back onto the slip sheet 10 and reused as desired.

[0031] Where no such outlet is provided, the bag can be opened in any fashion, such as through the opening at the top, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com