Manufacture method of slip sheet of air conditioner compressor

A technology for air-conditioning compressors and manufacturing methods, applied in the direction of manufacturing tools, mechanical equipment, machines/engines, etc., can solve problems such as high cost and cumbersome processing procedures, and achieve the reduction of raw material costs, reduction of machining amount, and reduction of friction coefficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The first step, raw material preparation and smelting

[0038] According to the mass percentage of elements, C: 3.4%, Si: 2.2%, Mn: 0.7%, Cr: 0.4%, Mo: 0.4%, V: 0.3%, B: 0.06%, Ti: 0.1%, Nb: 0.25% , Cu: 0.25%, P<0.3%, S<0.1%, and the rest is Fe, weigh the prepared raw materials, put the prepared raw materials into an intermediate frequency induction furnace, heat up until all the raw materials are melted, and smelt into alloy cast iron raw iron Liquid, the furnace temperature is 1525 ℃;

[0039] The second step, inoculation treatment

[0040] Carry out inoculation treatment with the alloy cast iron raw iron melt that melts out of the furnace in the first step, the inoculant is barium-silicon ferroalloy FeSi72Ba2, and its addition is 0.7% of the above-mentioned former molten iron quality;

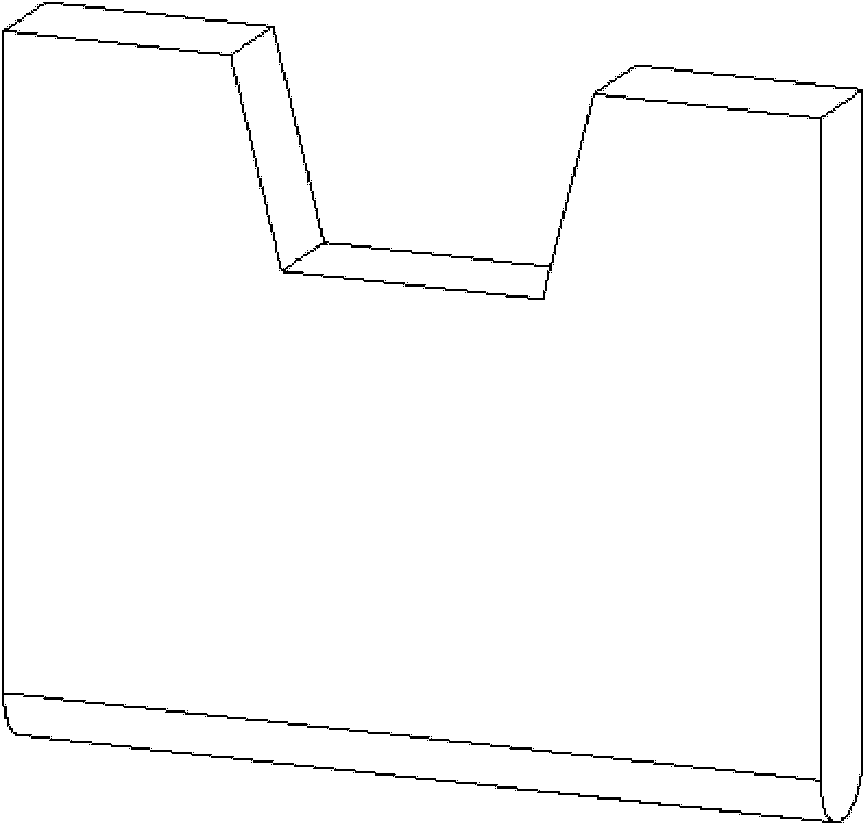

[0041] The third step, casting

[0042]The alloy cast iron stock solution inoculated in the second step is poured into the prefabricated coated sand shell mold, and after cooling, ...

Embodiment 2

[0053] The first step, raw material preparation and smelting

[0054] According to the mass percentage of elements, C: 3.2%, Si: 2.0%, Mn: 0.5%, Cr: 0.2%, Mo: 0.1%, Ti: 0.04%, P<0.3%, S<0.1%, and the rest are Fe, Weigh the prepared raw materials, put the prepared raw materials into an intermediate frequency induction furnace, raise the temperature until all the raw materials are melted, and smelt them into alloy cast iron raw iron, and the furnace temperature is 1500°C;

[0055] The second step, inoculation treatment

[0056] Carry out inoculation treatment with the alloy cast iron raw iron melt that melts out of the furnace in the first step, the inoculant is barium-silicon ferroalloy FeSi72Ba2, and its addition is 0.4% of the above-mentioned former molten iron quality;

[0057] The third step, casting

[0058] The alloy cast iron stock solution inoculated in the second step is poured into the prefabricated investment casting shell mold, and after cooling, the pearlite matr...

Embodiment 3

[0069] The first step, raw material preparation and smelting

[0070] According to the mass percentage of elements, C: 3.8%, Si: 2.6%, Mn: 1.0%, Cr: 0.6%, Mo: 0.6%, V: 0.5%, B: 0.1%, Ti: 0.15%, Nb: 0.5% , Cu: 0.5%, P<0.3%, S<0.1%, and the rest is Fe, weigh the prepared raw materials, put the prepared raw materials into an intermediate frequency induction furnace, heat up until all the raw materials are melted, and smelt into alloy cast iron raw iron Liquid, the furnace temperature is 1550 ℃;

[0071] The second step, inoculation treatment

[0072] Carrying out inoculation treatment to the alloy cast iron raw iron melt melted out of the furnace in the first step, the inoculant is barium-silicon ferroalloy FeSi72Ba2, and its addition is 1.0% of the above-mentioned former molten iron mass;

[0073] The third step, casting

[0074] The alloy cast iron stock solution inoculated in the second step is poured into the prefabricated coated sand shell mold, and after cooling, a pearl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com