Rotary compressor

A technology of rotary compressor and compression mechanism, applied in the direction of rotary piston machinery, rotary piston pump, mechanical equipment, etc., can solve the problems of bearing rigidity decrease, compression cavity deformation, reliability decrease, etc. The effect of improving strength and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

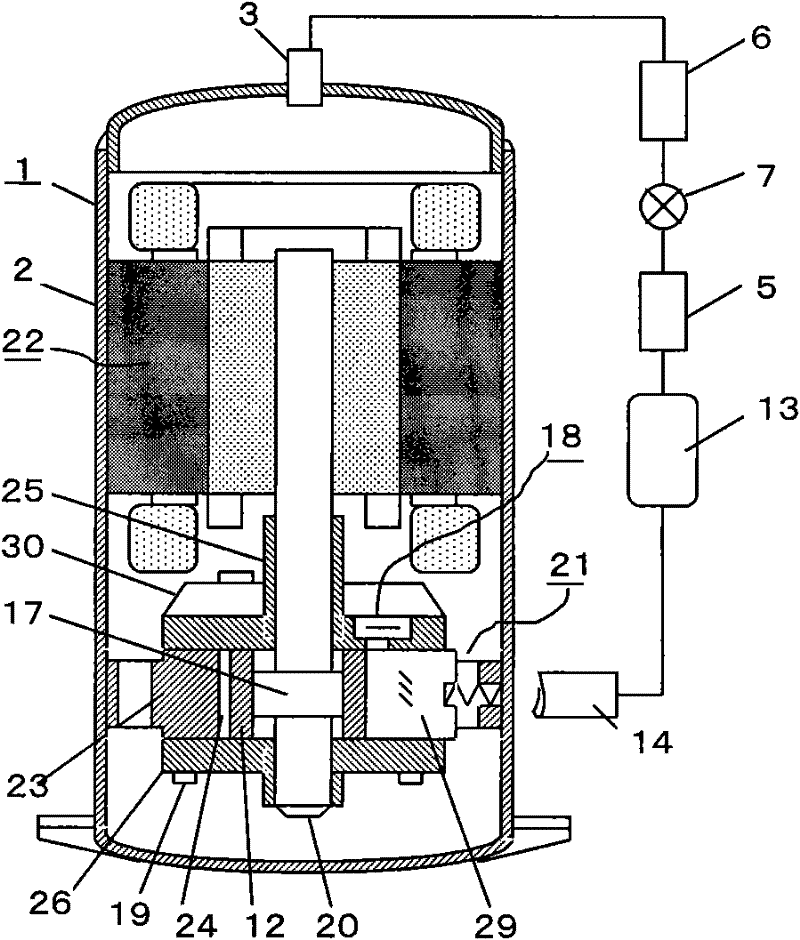

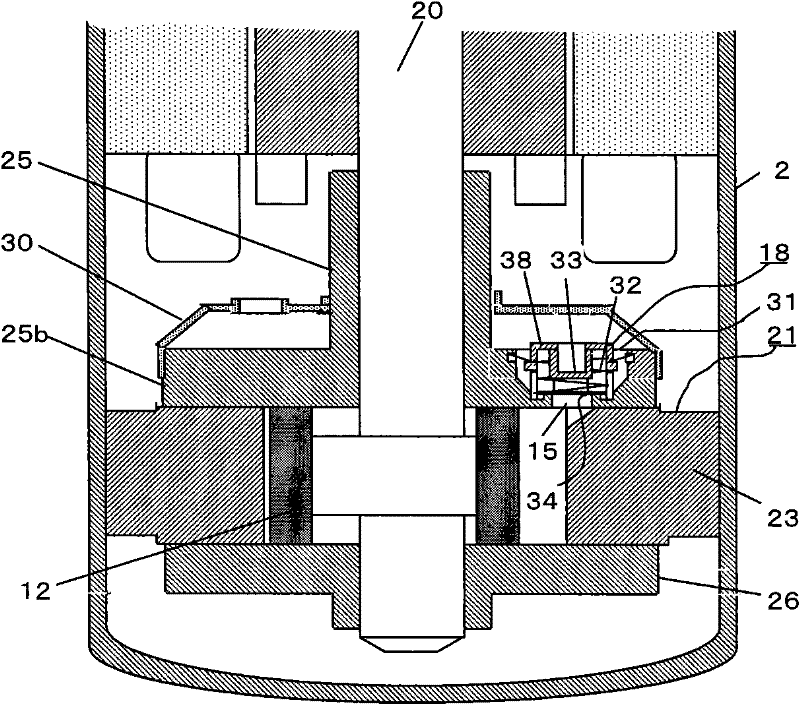

[0048] see figure 1 , the rotary compressor 1 is composed of a compression mechanism part 21 installed in the sealed casing 2 and a motor part 22 arranged on the top thereof. The compression mechanism part 21 is supported by a cylinder 23, a piston 12 that rotates eccentrically in the cylinder compression chamber 24, a sliding plate 29 that reciprocates synchronously with the piston 12, and a crankshaft 20 that drives the piston 12 through an eccentric shaft 17 arranged on it. The main bearing 25 and the sub bearing 26 of the crankshaft 20 are comprised. On the upper part of the main bearing 25, the discharge muffler 30 which was press-processed is arrange|positioned. The above components are connected and assembled with screws 19 to complete the compression mechanism unit 21 . The assembled compression mechanism part 21 and motor part 22 are fixed in the sealed case 2 , and then a head is welded to the sealed case 2 to complete the rotary compressor 1 .

[0049] In a refri...

Embodiment 2

[0082] In Example 1, the press-worked discharge muffler 30 is attached to the upper part of the main bearing flat part 25b. Figure 15-Figure 17 In the illustrated second embodiment, the discharge valve device is accommodated in the silencer chamber instead of the discharge silencer 30 by providing the silencer chamber 51 inside the main bearing flat portion 25b of the sealed main bearing 27 in advance. As a result, the rigidity and sound-proof effect of the sealed main bearing 27 can be improved; and, as will be described later, the sound-absorbing chamber 51 can be completely sealed.

[0083]The assembly groove in this embodiment is the second assembly groove 55, and the discharge valve plate is the second discharge valve plate 58 with a cutout 59, the second assembly groove 55 communicates with the silencer cavity 51, and the upper and lower mechanisms in the discharge valve device include a sealing cover 57, the sealing cover is fixed in the muffler cavity 51, an air passa...

Embodiment 3

[0095] As mentioned above, the embodiment of the silencer chamber 51 formed integrally by the sealed main bearing 27 through casting has been described; however, the sealed main bearing 27 can also be realized through a technical solution in which two components are connected, that is, the first zero After part 61a and second part 61b are connected, also can obtain and the equivalent effect of above-mentioned technical scheme, see Figure 19 . In this case, the two parts are connected, for example, by copper brazing or laser welding. Comparing this technical solution with the one-piece casting solution related to castings, it can be concluded that the technical solution for the connection of two parts has the disadvantages of increasing the number of welding points of the parts and the amount of connection work, but it does not require the core necessary for the casting method And the advantages of easy machining. The number of connection points of two parts is not limited t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com