Axial feeding device and charging docking device

A technology of axial feed and motor seat, which is applied in the field of mechanical arms, can solve the problems of inability to adjust the operating direction or operating position, and achieve the effect of simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

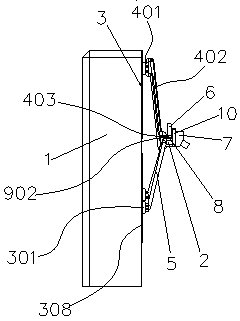

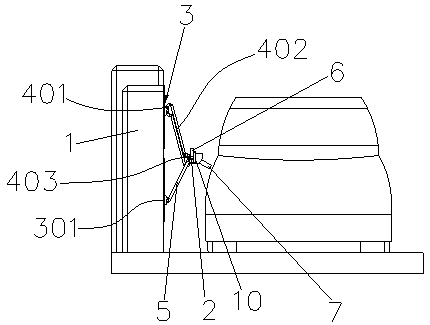

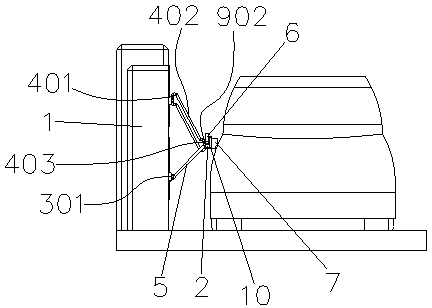

[0074] like Figure 1-Figure 6 The shown embodiment one of an axial feed device of the present invention includes a base 1 and an adjustment seat 2, and one side of the base 1 is provided with three linear drive devices 3, and each linear drive device 3 includes a linear As for the motion component, the moving trajectories of the three linear motion components are arranged in parallel and form a character shape; among the three linear motion components, the middle linear motion component is rotated and connected to a limit rod 401, and both ends of the limit rod 401 are hinged. Fork 402, movable rod 403 is hinged between two swing rods 402, limit rod 401, two swing rods 402 and movable rod 403 constitute a parallelogram mechanism, and the motion track line of the linear motion component in the middle is consistent with the parallelogram mechanism. The motion trajectory curves are all located on the same plane, the movable rod 403 is installed on the adjustment seat 2, and the ...

Embodiment 2

[0094] like Figure 16-Figure 17 Shown is the second embodiment of an axial feed device of the present invention. The difference between this embodiment and the first embodiment is that the linear drive device 3 is a rack and pinion transmission device, wherein, when the linear motion component is a rack 304, the side of the base 1 is provided with a first groove 12 and a second motor 13, the gear 302 is arranged in the first groove 12, and the output shaft of the second motor 13 passes through the side wall of the first groove 12 and Stretch in the slot, the gear 302 is installed on the output shaft of the second motor 13, the gear 302 and the rack 304 mesh with each other, and the two sides of the rack 304 are successively provided with a plurality of protrusions 303 along the length direction, and the first groove The groove walls on both sides of 12 are provided with strip-shaped grooves 1201 along the direction of the groove body, and each protrusion 303 is slidably conne...

Embodiment 3

[0097] like Figure 18-Figure 19The third embodiment of an axial feed device of the present invention is shown. The difference between this embodiment and the first embodiment is that the linear drive device 3 is another rack and pinion transmission device, wherein the linear motion assembly includes Gear 302, slide block 307 and second motor 13, rack 304 are installed on the side of base 1, and rack 304 two ends are provided with end plate 305, two end plates 305 are vertically fixed on the side of base 1, two Several guide rods 306 are vertically fixedly connected between each end plate 305, and the slider 307 is slidably connected to each guide rod 306. The second motor 13 is installed on the slider 307, and the gear 302 is installed on the output shaft of the second motor 13. , the gear 302 and the rack 304 mesh with each other. The second motor 13 drives the gear 302 to roll on the rack 304 , and then drives the slider 307 to slide on the track formed by the guide rods 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com