Preparing method for quadrpyramid microstructure array

A microstructure array and quadrangular pyramid technology are applied in the field of fabrication of quadrangular pyramid microstructure arrays, which can solve the problems that affect the application effect of components and cannot be used to manufacture quadrangular pyramid microstructure arrays, etc. Guarantee the effect of surface shape accuracy and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0038] Example 2, making a small-diameter continuous deep-relief microstructure array with a diameter k=17 μm. Adopt positive photoresist to be photoresist material, etching depth h=5 μm, its fabrication steps are as follows (similar to the step that adopts with embodiment 1):

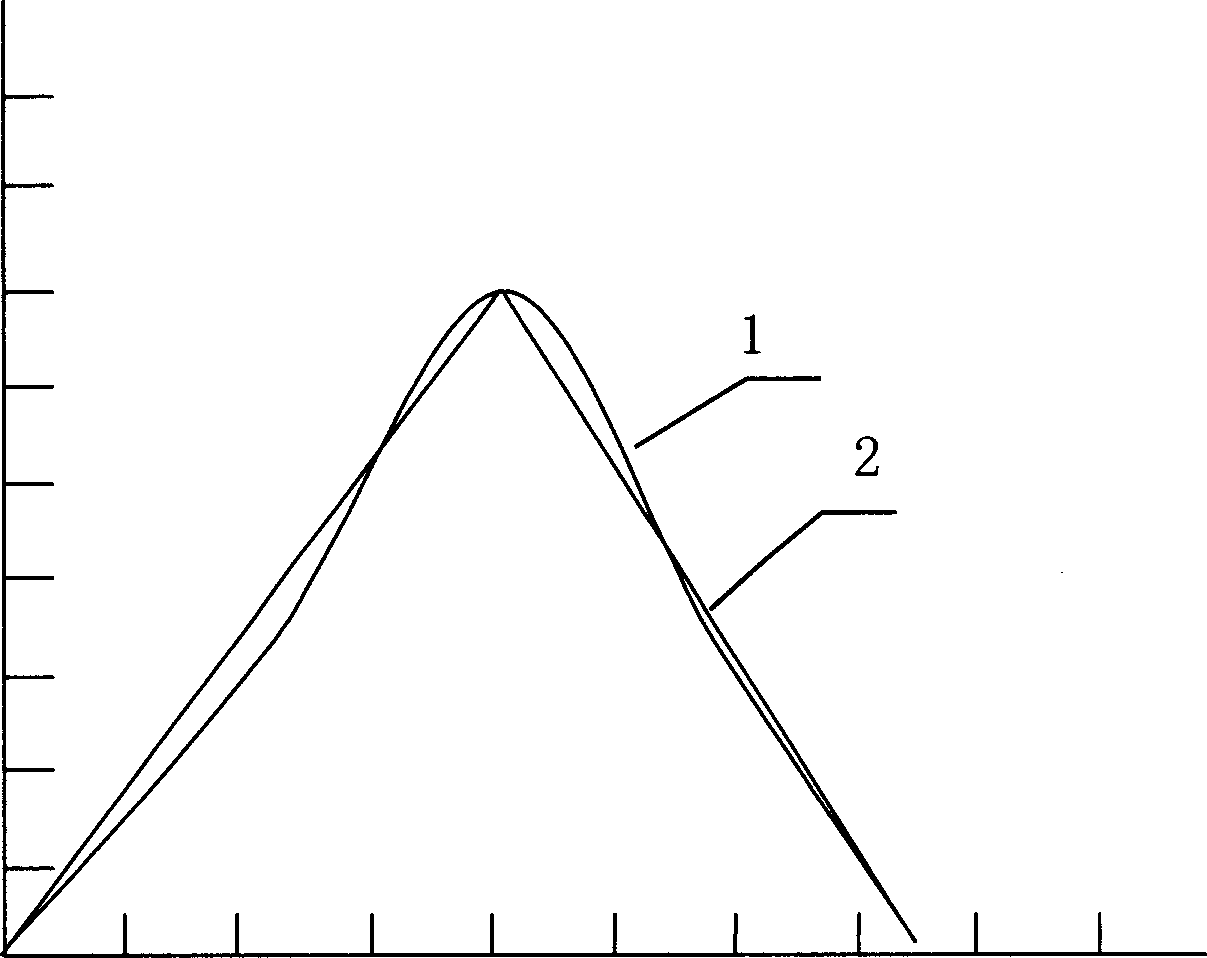

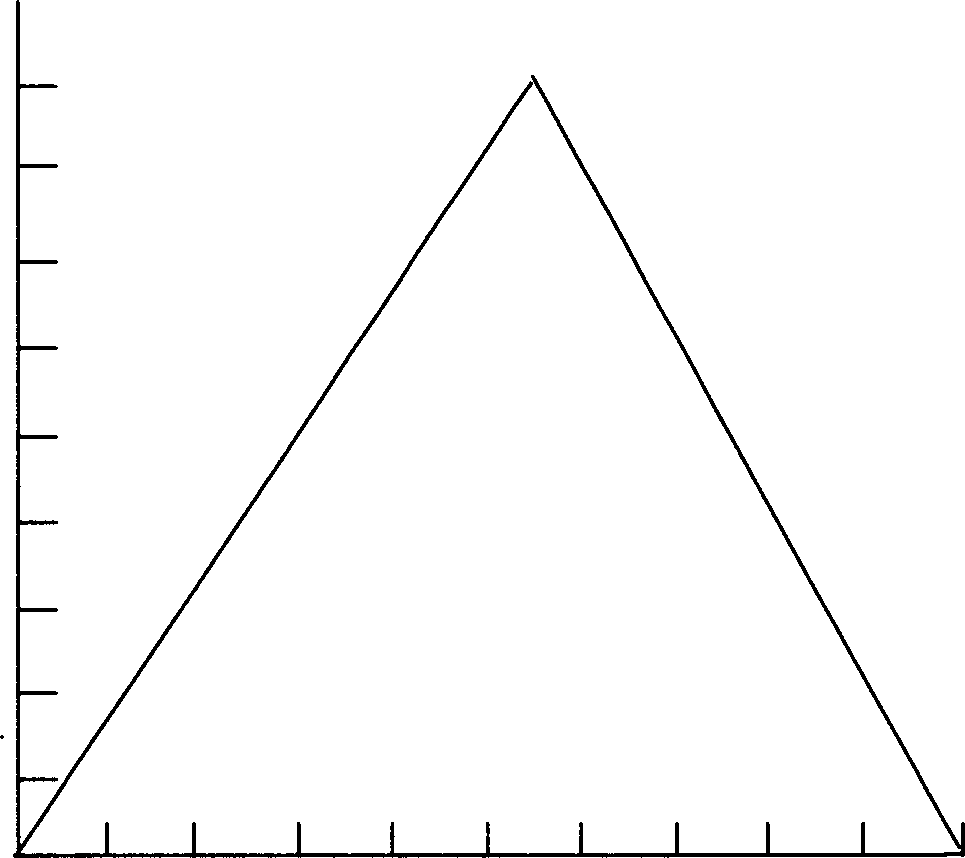

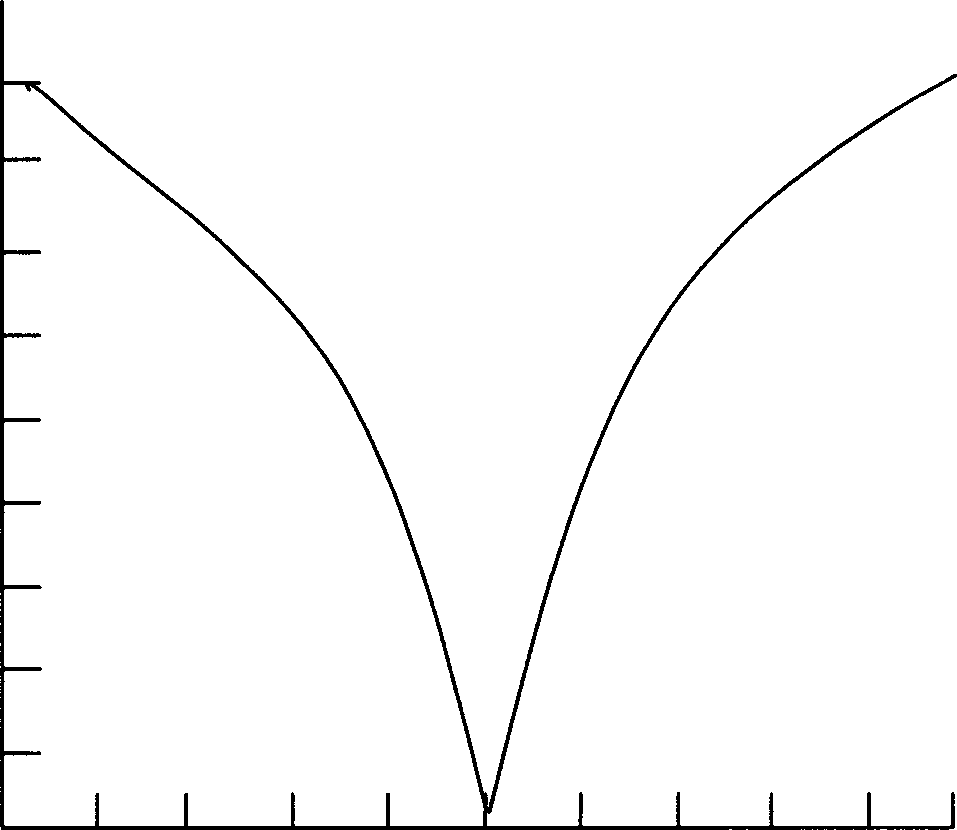

[0039] (1) According to the etching depth h=5 μm and the etching aperture k=17 μm of the microstructure array relief to be etched, calculate the cross-sectional view f(x) of the microstructure relief;

[0040] (2) According to the micro-relief structure f(x), the mask unit pattern g required for processing the quadrangular pyramid microstructure 0 (x) design;

[0041] (3) Using laser direct writing technology for mask direct writing;

[0042] (4) Using the projection exposure system, project the prepared mask unit on the photoresist for cross-exposure, and move the mask continuously during the exposure process;

[0043] (5) Perform timing development and hardening of the photoresist after continuous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com