Automatic injecting interface

A technology of receiving interface and output interface, which is applied in the field of filling interface, can solve the problems of long information loop, difficulty in ensuring information security, and low connection stability, and achieve the effect of reducing control precision requirements and simple information interaction mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the present invention includes but not limited to the following embodiments.

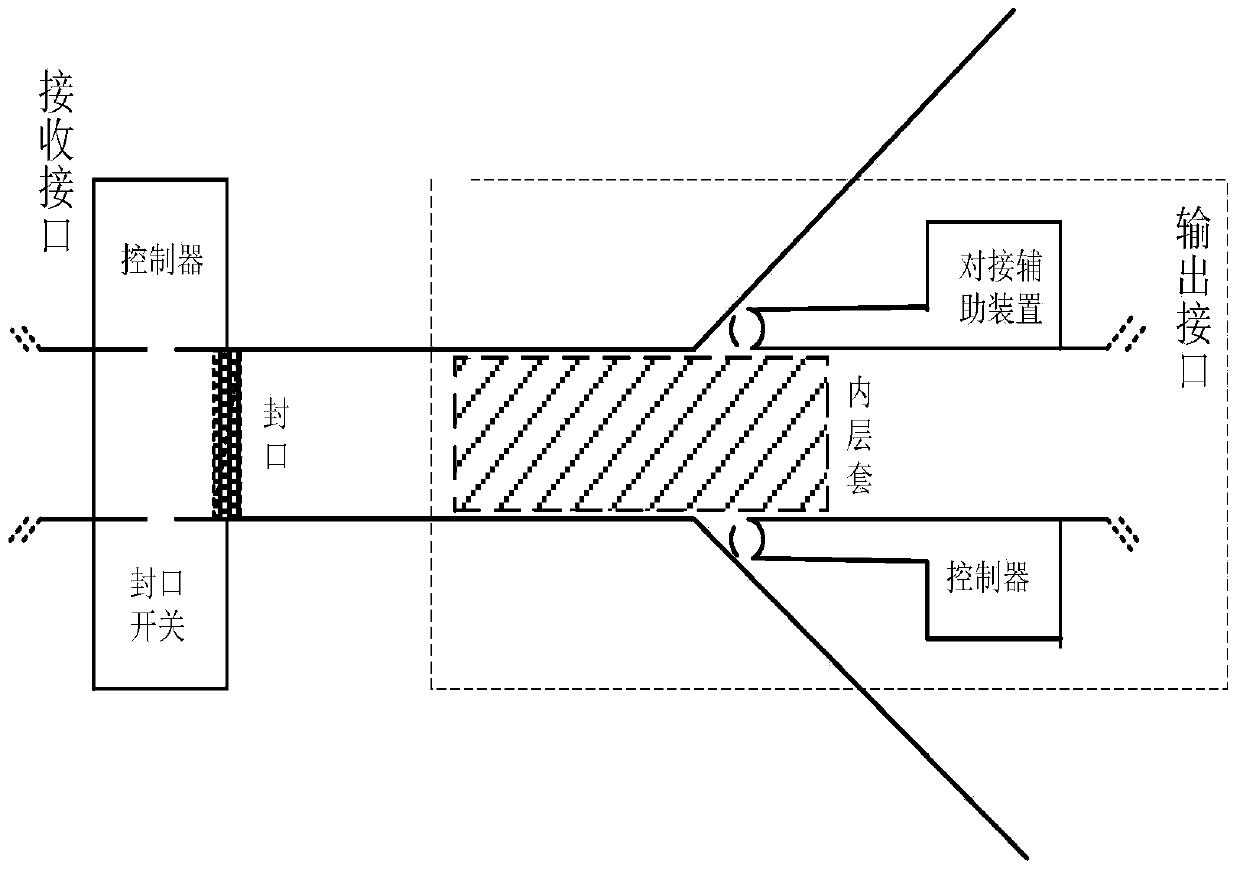

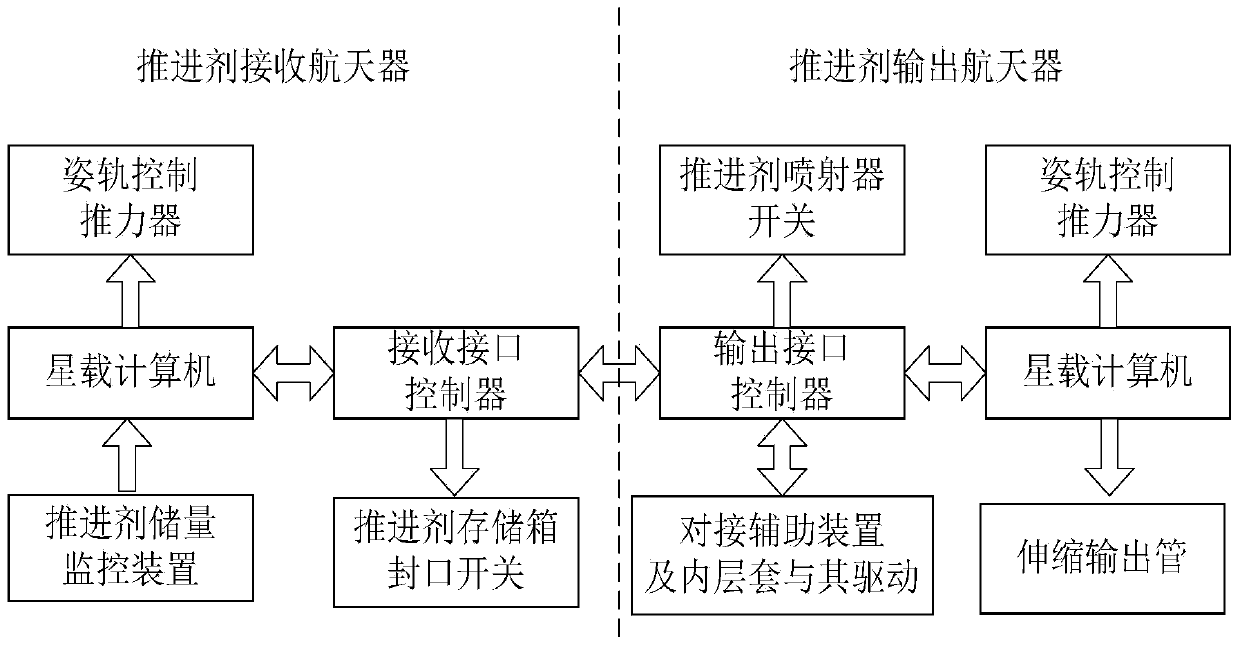

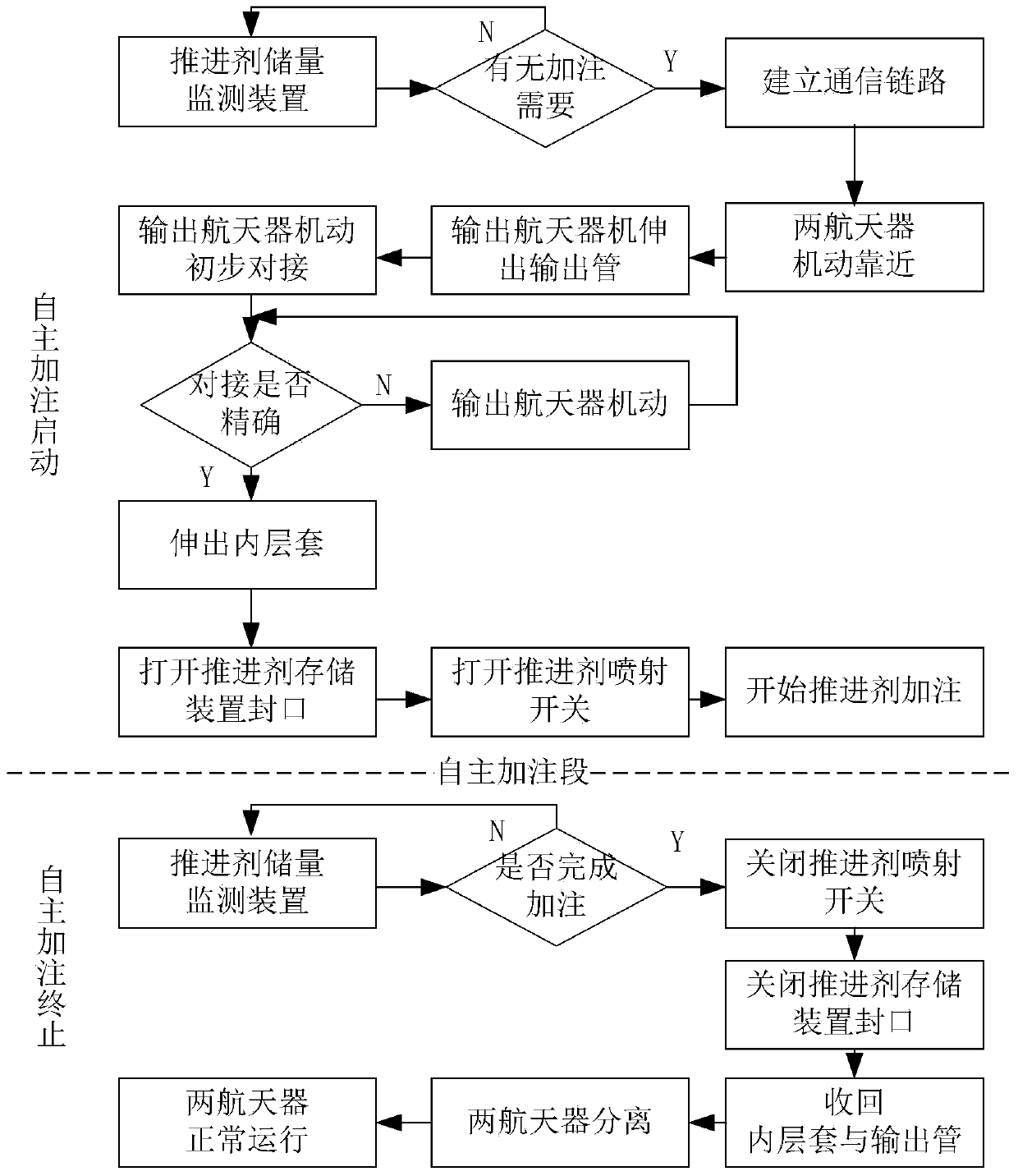

[0013] The present invention mainly relates to an autonomous filling interface. The purpose of the invention is to achieve Fluid filling between platforms is autonomous. The main principle is to use the tapered receiving port to expand the detection target, reduce the control requirements, and use the shape of the two interfaces to achieve preliminary fixation. The docking aid with a built-in pressure-sensitive identifier and port spherical treatment senses the pressure and generates a corresponding signal. In the case of inaccurate docking, the output rod slides under the action of force along the direction of the rod and the inner wall of the tapered interface to form a precise docking, and the inner sleeve extends into the receiving interface to achieve a stable connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com