Preparation method of chemical toughened glass product with wearing-resisting film

A technology for chemically toughened glass and glass products, which is applied in glass manufacturing equipment, glass tempering, manufacturing tools, etc. It can solve the problems of limited increase in glass strength, poor ion exchange effect, and reduced thickness of tempered layer, so as to improve the resistance Ability to rub and scratch, improve dispersibility, effect of improving dispersibility of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

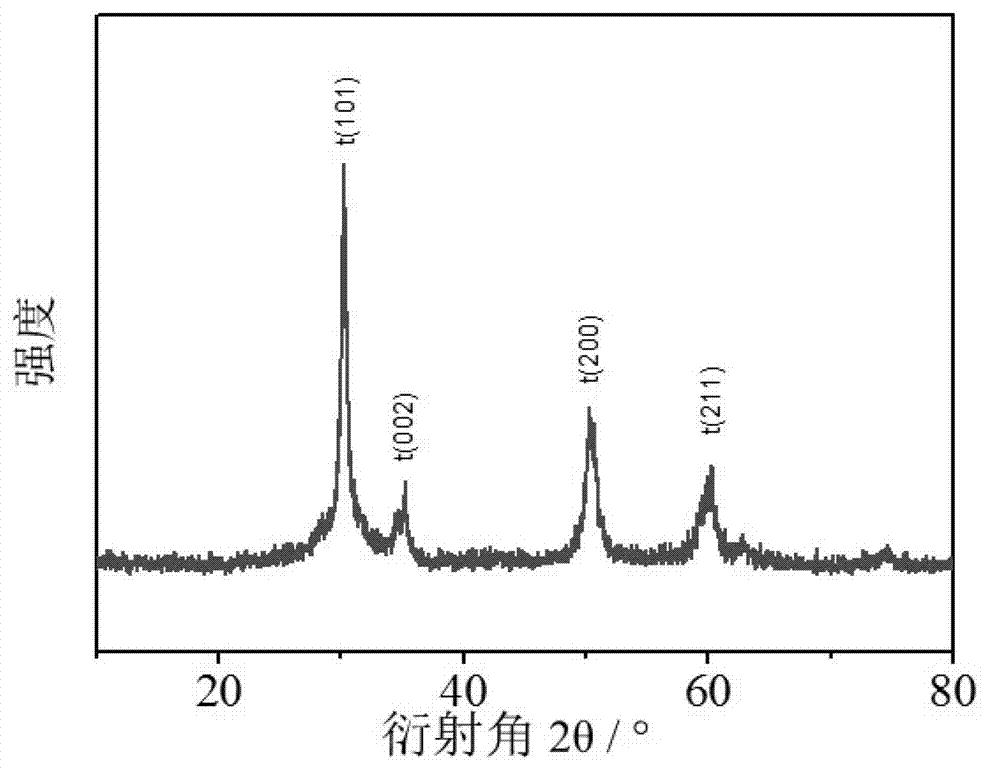

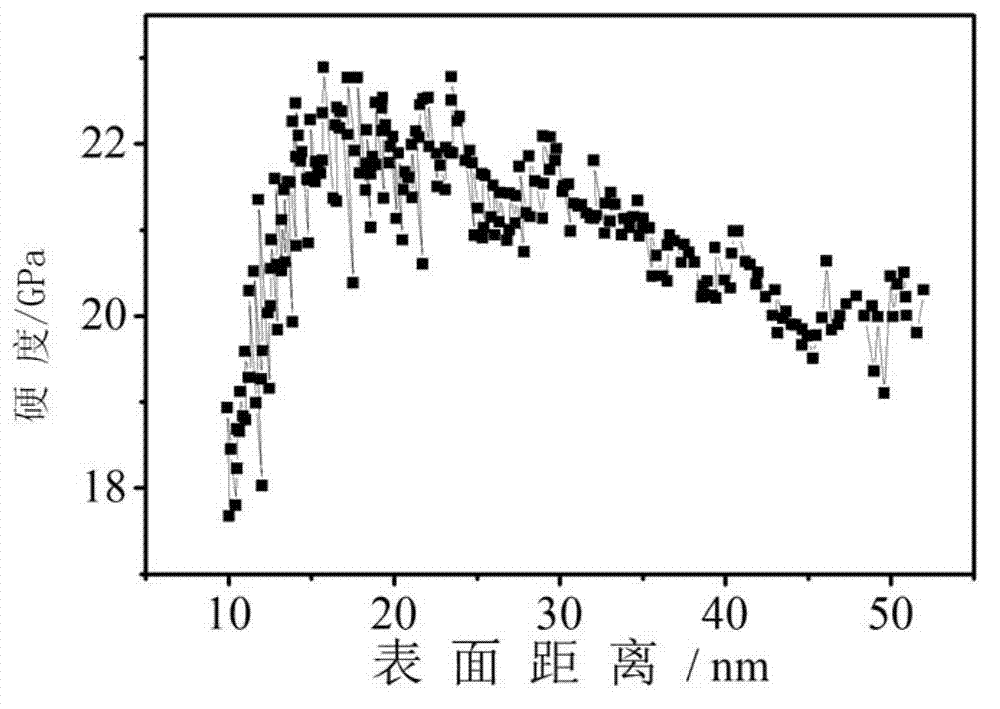

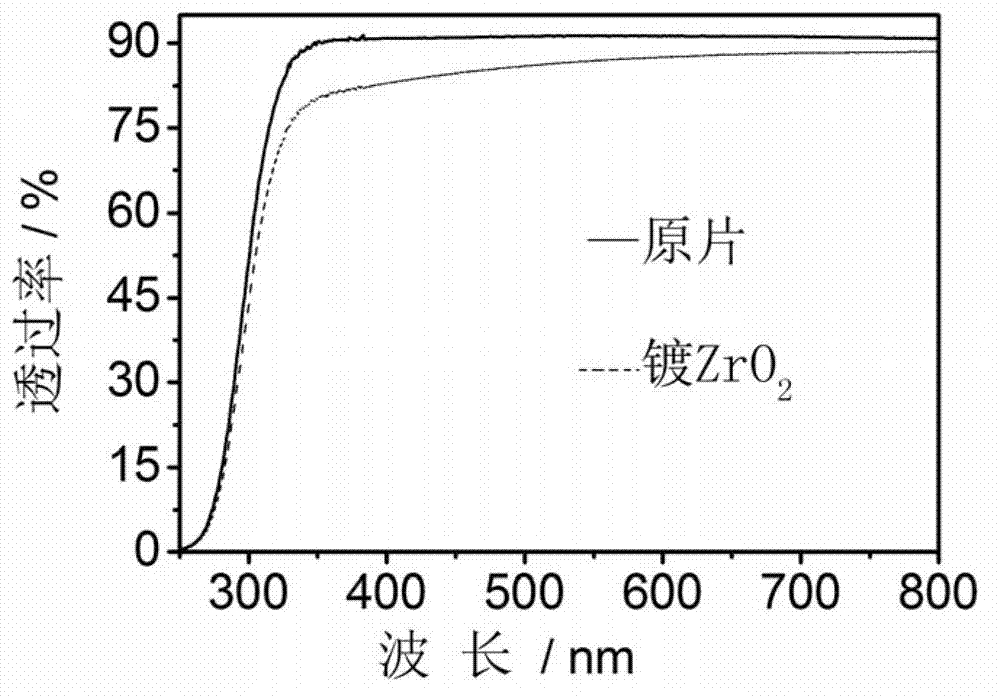

[0044] Embodiment 1: preparation surface ZrO is plated 2 Wear-resistant film chemically tempered flat soda lime glass

[0045] Zirconium oxychloride, deionized water, ethanol, and hydrogen peroxide are used as raw materials, wherein the volume ratio of deionized water to ethanol is 1:4, and zirconium oxychloride is 2% of the total mass of deionized water+ethanol based on the mass of zirconia, The molar ratio of hydrogen peroxide to zirconium oxychloride is 4:1. At room temperature, each substance was added sequentially for about 4 hours with thorough stirring, and a colorless transparent sol was formed. After aging for 6 hours, the viscosity of the sol reaches the coating requirement, and the viscosity of the sol is stabilized by dripping 0.5% dilute nitric acid in an amount of 0.5ml per 100ml of sol. After the sol was coated on the cleaned flat glass surface by the pulling method, the product was dried in an oven at 60°C for 30 minutes, then placed in a muffle furnace at 55...

Embodiment 2

[0046] Embodiment 2: Prepare the surface to plate SnO 2 Wear-resistant film chemically tempered flat soda lime glass

[0047] Use tin chloride, deionized water, ethanol, and hydrogen peroxide as raw materials, wherein the volume ratio of deionized water to ethanol is 1:4, tin chloride is 5% of the total mass of water+ethanol based on the mass of tin oxide, and hydrogen peroxide is added to chlorinate The amount of tin molar ratio 4. At room temperature, each substance was added sequentially for about 4 hours with thorough stirring, and a colorless transparent sol was formed. After aging for 6 hours, the viscosity of the sol reaches the coating requirement, and the viscosity of the sol is stabilized by dripping 0.5% dilute nitric acid in an amount of 0.5ml per 100ml of sol. After the sol was coated on the cleaned flat glass surface by the pulling method, the product was dried in an oven at 60°C for 30 minutes, then placed in a muffle furnace at 550°C for 2 hours in an air atm...

Embodiment 3

[0048] Embodiment 3: prepare surface plated Al 2 o 3 Wear-resistant film chemically tempered flat soda lime glass

[0049] Aluminum chloride, deionized water, ethanol, and propylene oxide are used as raw materials, wherein the volume ratio of deionized water to ethanol is 1:4, aluminum chloride is 2% of the total mass of water+ethanol based on the mass of alumina, and epoxy Propane is added in an amount of 6 molar ratios to aluminum chloride. At room temperature, the substances were added sequentially for about 7 hours with thorough stirring, and a colorless transparent sol was formed. After aging for 15 hours, the viscosity of the sol reaches the coating requirement, and the viscosity of the sol is stabilized by dropping 0.5% dilute nitric acid in an amount of 0.5 ml per 100 ml of sol. After the sol was coated on the cleaned flat glass surface by the pulling method, the product was dried in an oven at 60°C for 30 minutes, then placed in a muffle furnace at 550°C for 2 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com