Flapping wing unit of flapping wing aircraft

A flying machine and wing handle technology, applied in the field of flapping wing devices, can solve the problems of unstable flying state, small buoyancy, and large buoyancy changes of the flapping wing flying machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

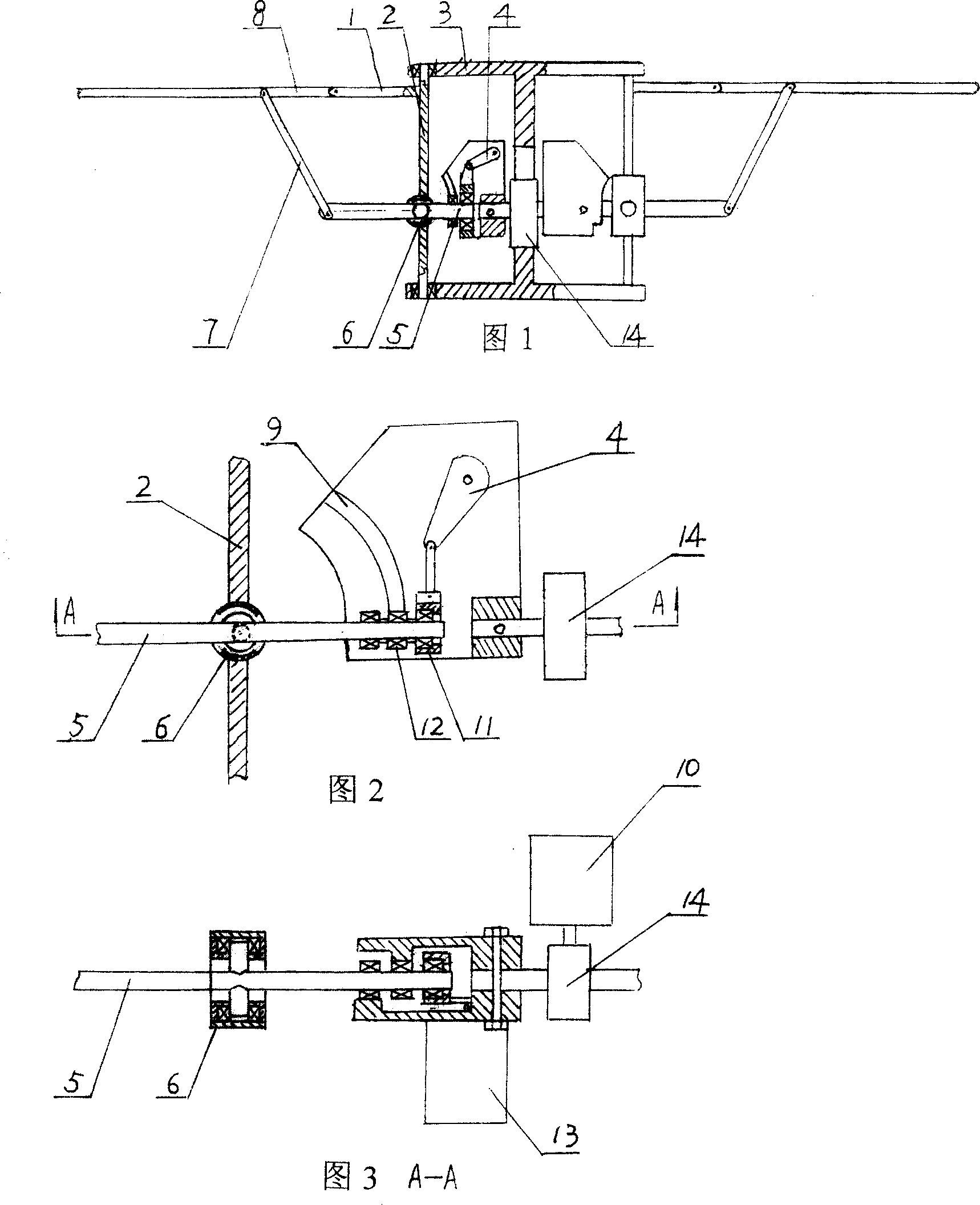

[0010] A flapping wing device of a flapping wing aircraft, as shown in Figure 1, Figure 2, and Figure 3, includes a wing handle 8 connected to the wing, and a motor 10 installed on the base is respectively connected to two symmetrical steering gear drive. The motor 13 of the steering gear driving device is hinged to the bearing seat 11 installed at the end of the lever transmission shaft 5 through the crank linkage mechanism 4, and the roller 12 installed on the lever transmission shaft 5 cooperates with the slideway 9 in the steering gear housing, and the slideway 9 is an outwardly convex or inwardly concave arc-shaped track. The bearing seat 6 matched with the lateral symmetrical support shaft affixed to the middle part of the lever transmission shaft 5 is arranged on the rotating shaft 2, and the two ends of the rotating shaft 2 are installed on the casing 3 through bearings. The bearing seat 6 is a cylindrical bearing seat, and the middle part of the cylinder is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com