Drill bit with staged durability, stability and ROP characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

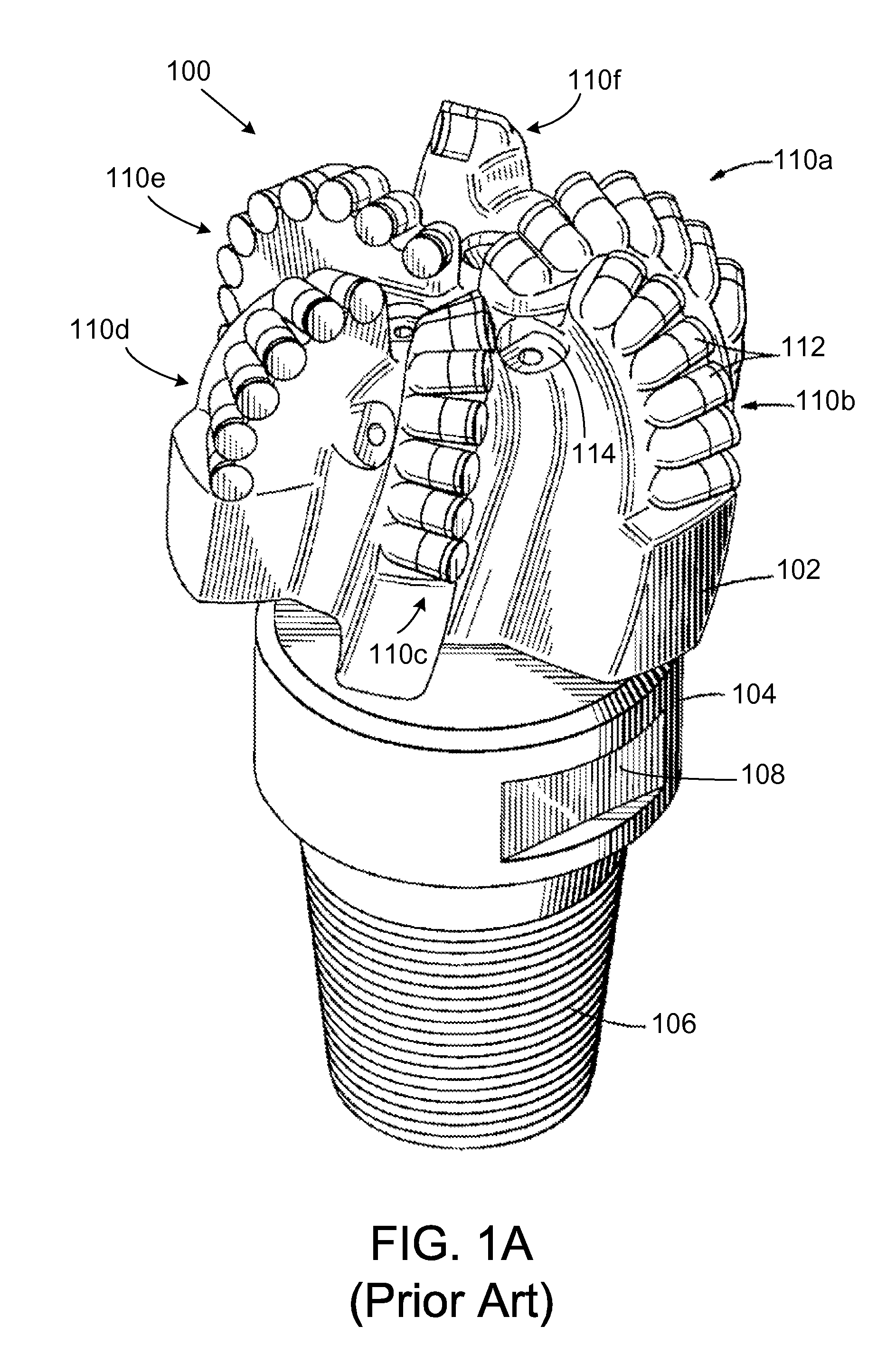

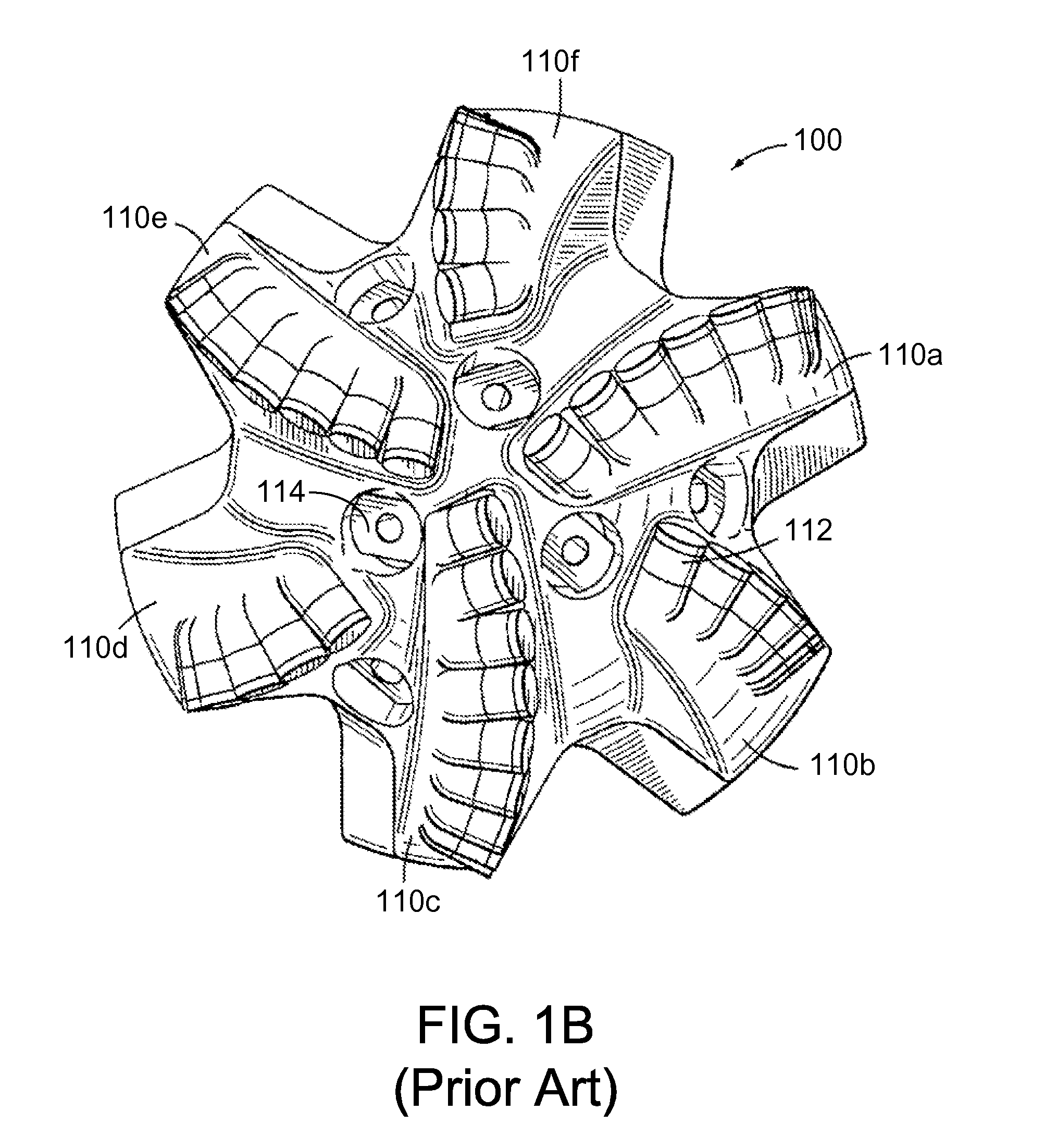

[0036] Following is a detailed description of the invention with reference to the drawings. It should be noted that the drawings are provided for illustrative purposes only and are not intended to be a blueprint or manufacturing drawings, nor are they drawn to any particular scale.

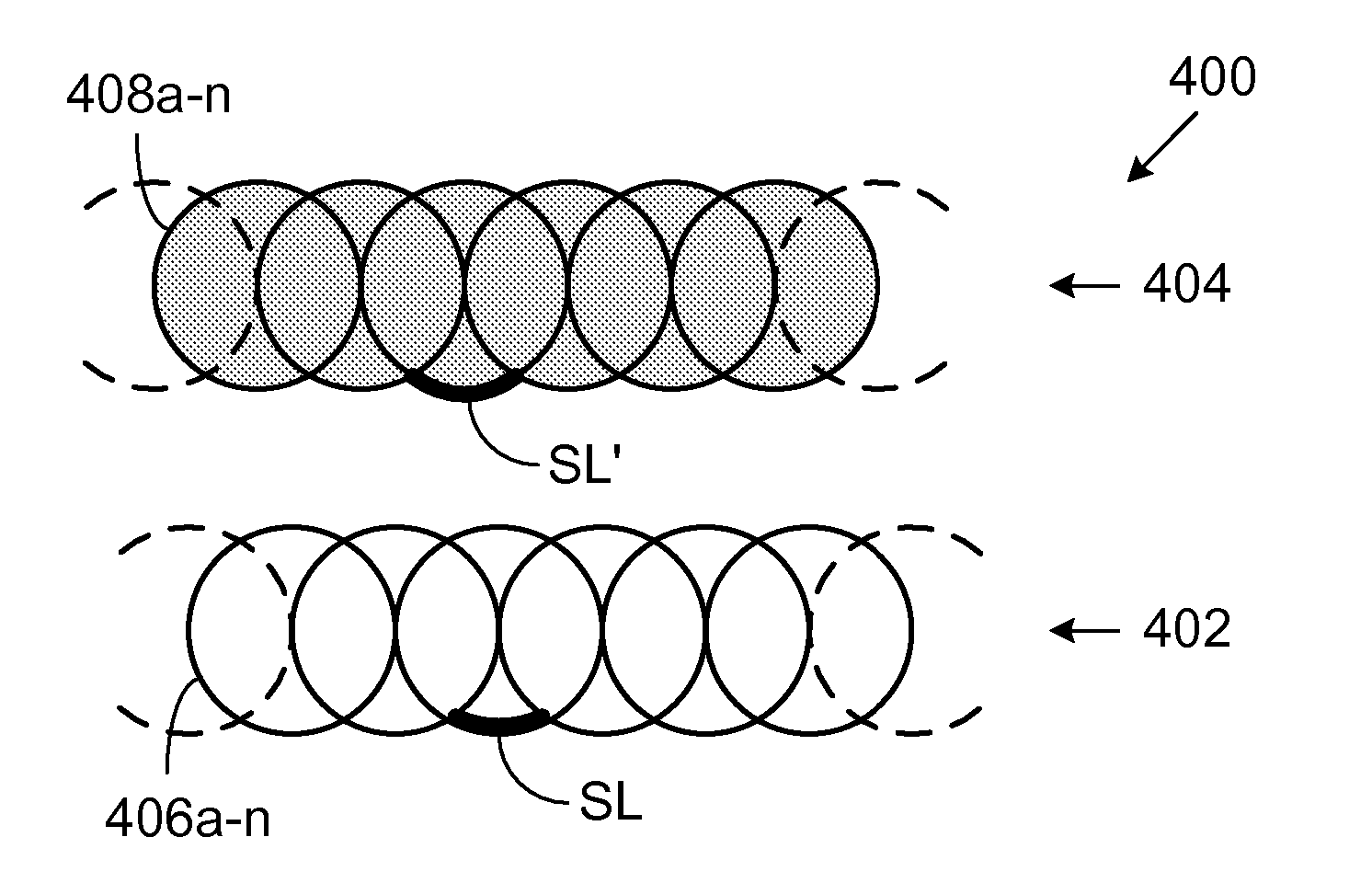

[0037] As mentioned above, existing drill bits have primary layer and secondary layer cutting elements that are uniform in size and shape and share the same radial positions. This results in the cutting elements of the secondary layers following an identical swath through the subsurface formation as the cutting elements of the primary layers. Consequently, the primary layer and secondary layer cutting elements do not establish independent coverage of the bottom hole. In this regard, the tips of the cutting elements in the different layers, which are the first points of contact with the formation being drilled, begin to fail or deteriorate along a common line. Such failure initiation at the tips of the cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com