Composite inserted tooth blade diamond comprehensive drill bit

A diamond and drill bit technology, applied in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of high cost, short pure drilling time, no footage, etc., and achieve the effect of short life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

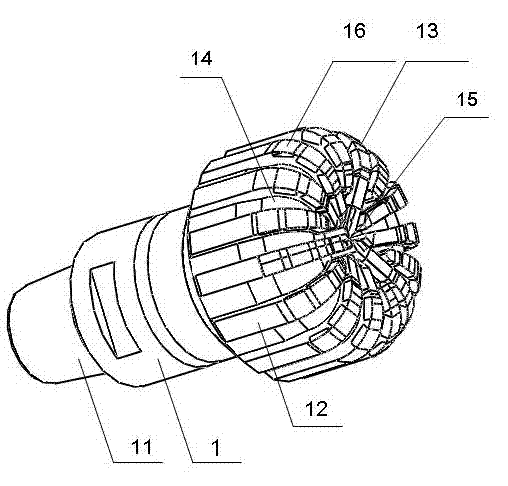

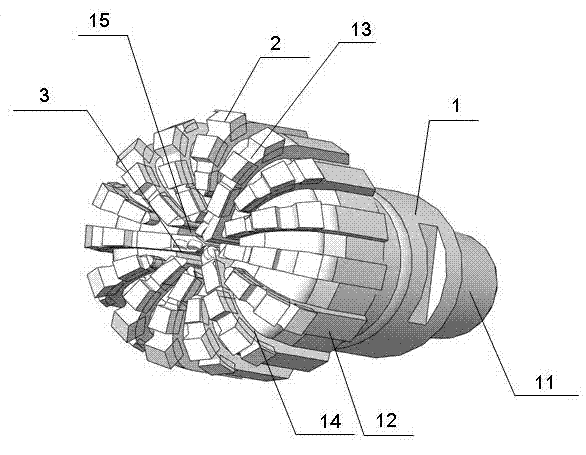

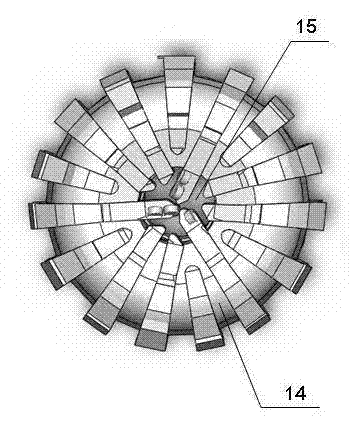

[0013] Such as figure 2 As shown, the compound insert blade type diamond comprehensive drill bit of the present invention is welded on the blade 13 of the drill base body 1 by a special, different structural shape, high strength, high wear resistance superhard material cutting abrasive block. form.

[0014] Such as figure 1 , figure 2 As shown, the drill base 1 is composed of a joint 11 , a gauge surface 12 , a blade 13 , a waterway 14 , and a central water hole 15 . recombine figure 1 , A replacement block 16 is reserved in the blade 13, the shape and size of the replacement block 16 vary according to the arrangement position, and it is used for welding the cutting abrasive block 2 and the diamond composite sheet 3. Cutting abrasive blocks 2 are inlaid and welded at multiple positions of the blade 13 , and the diamond composite sheet 3 is inlaid and w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com