Waterpower oscillator

A technology of hydraulic oscillator and vibration valve, which is applied in vibration drilling and other directions, can solve the problems of restricting drill pressure, large positive pressure, and increased drilling tool friction, so as to absorb drill string vibration and drill bit impact force, and relieve lateral pressure. and longitudinal vibration, reducing the effect of back pressure phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

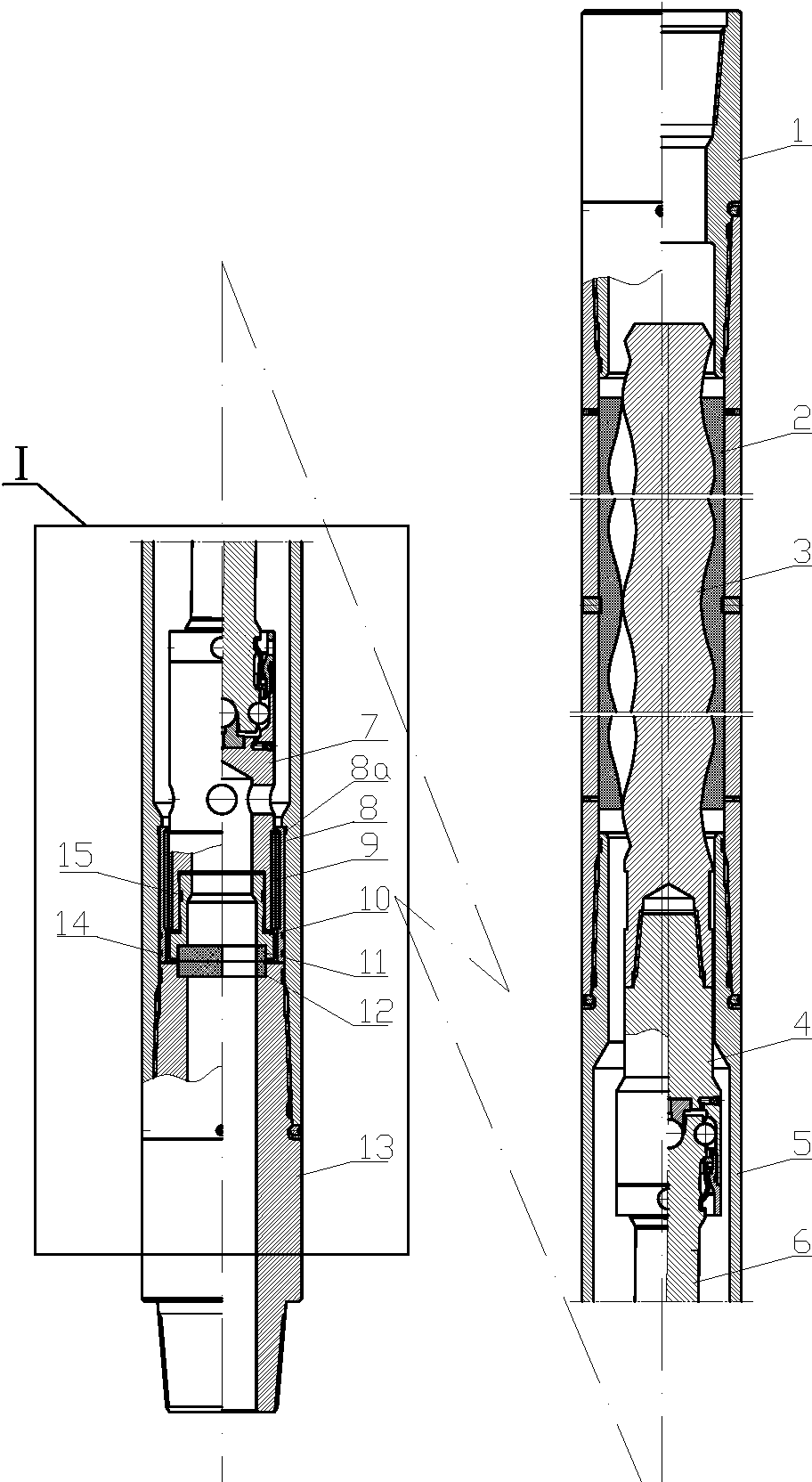

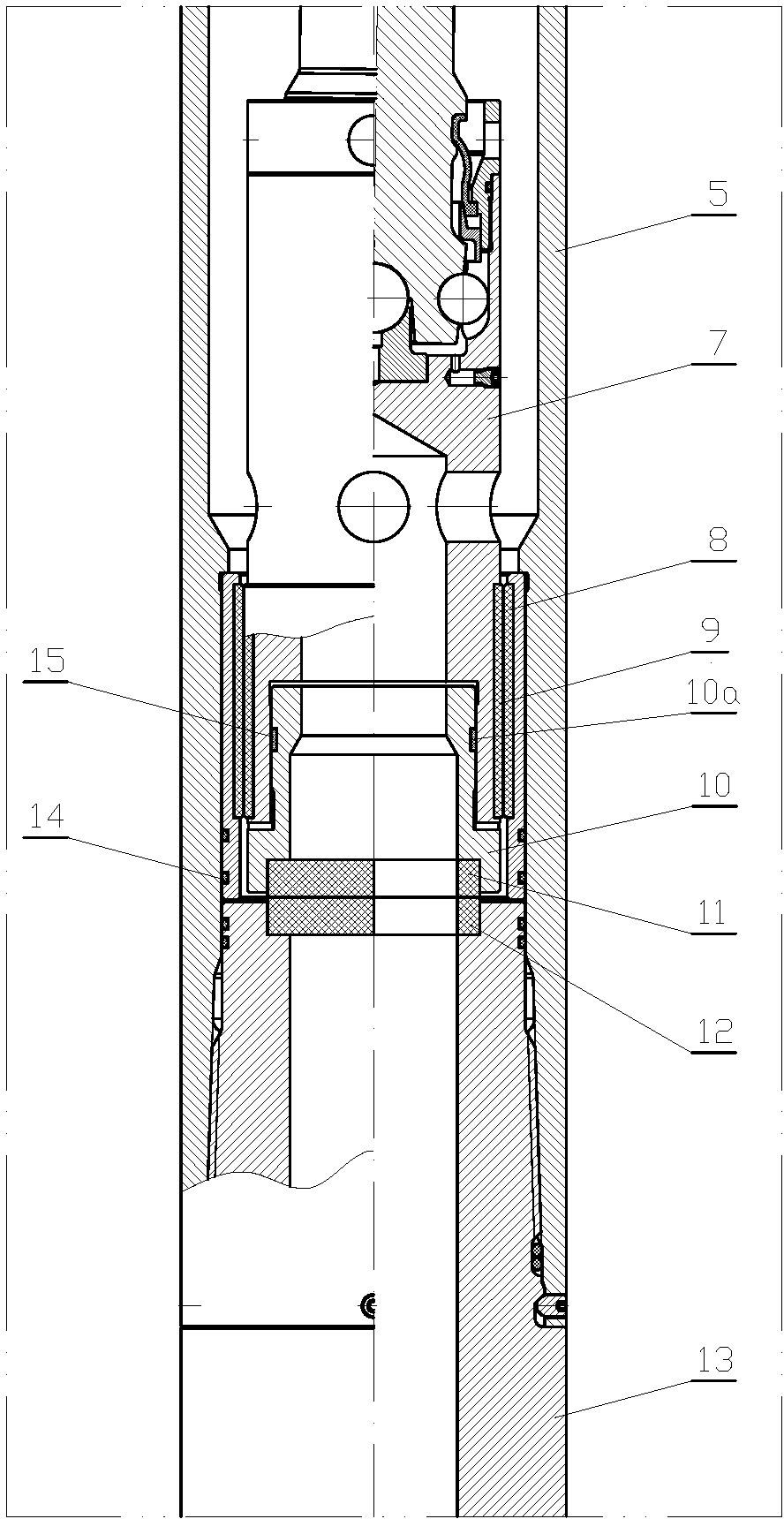

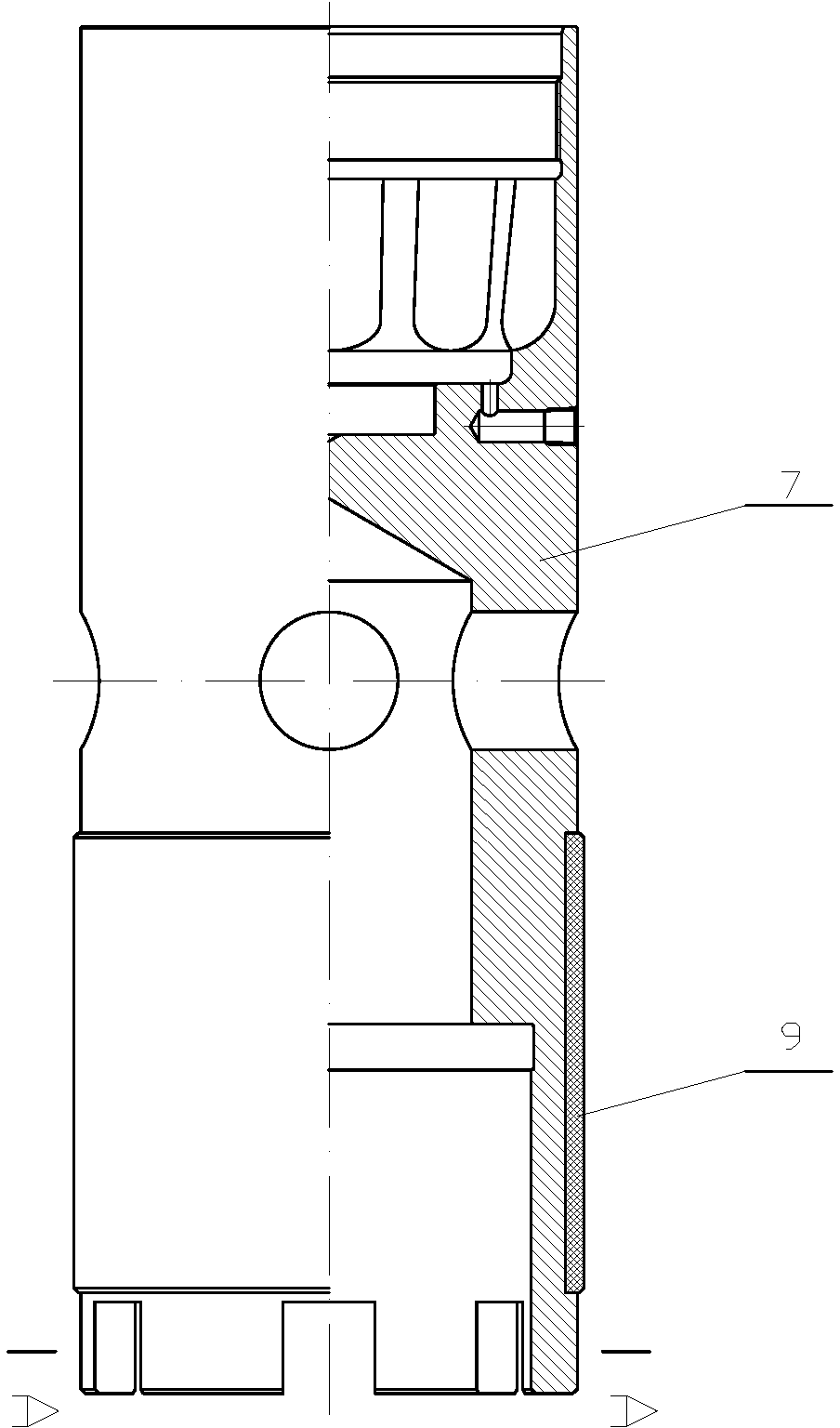

[0032] Such as figure 1 — Figure 12 The hydraulic oscillator of the present invention includes an upper joint 1, a stator 2, a casing 5 and a lower joint 13 which are sequentially sealed and connected, a rotor 3 is arranged eccentrically in the stator 2, and a cardan shaft is sequentially connected to the casing 5 at the lower end of the rotor 3. Joint 3, cardan shaft 6 and cardan shaft transmission rod 7, the outer circumference of the lower end of the cardan shaft transmission rod 7 is in sliding and sealing connection with the casing 5 through a sliding bearing component, the inner wall of the lower end of the casing 5 is in threaded connection with the lower joint 13, and the cardan shaft transmission The lower end of the rod 7 is matched with a vibrating valve 10, which can reciprocate and slide along the mating surface relative to the cardan shaft transmission rod 7. The lower end of the vibrating valve 10 is sealed with a moving valve plate 11 that operates synchronous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com