A kind of silicon amine base drilling fluid and preparation method thereof

A drilling fluid and silicon amine-based technology, applied in the fields of chemical instruments and methods, drilling compositions, organic chemistry, etc., can solve the problems of difficult rheological control and weak anti-pollution ability, so as to reduce the fluid loss of the system, Ease of operation and effect of reducing the amount of intrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

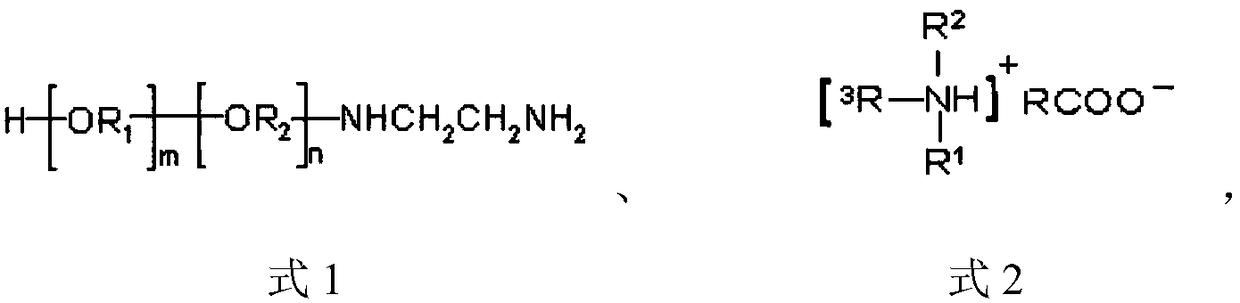

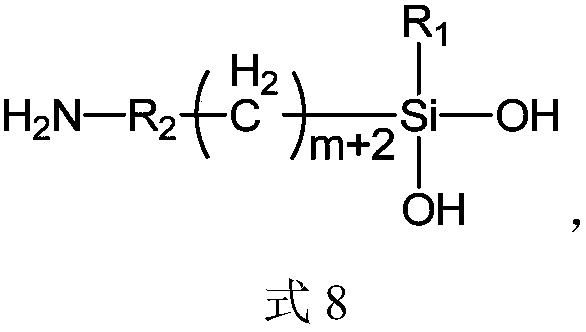

[0048] Silicon amine-based drilling fluid, composed of the following components in mass percentage: sodium bentonite 4%, sodium carboxymethylcellulose (CMC) 0.2%, hydrolyzed polyacrylamide potassium salt (KPAM) 0.3%, organic silicon potassium humate OSAM-K 2%, emulsified asphalt SFT 3%, aminosilanol inhibitor 1%, NaOH 0.2%, BaSO 4 20%, and the balance is water; wherein, the structural formula of the aminosilanol inhibitor is shown in formula 8, where R 1 is hydrogen, m is 0, R 2 In n, take 0.

[0049] The preparation steps of aminosilanol inhibitor are:

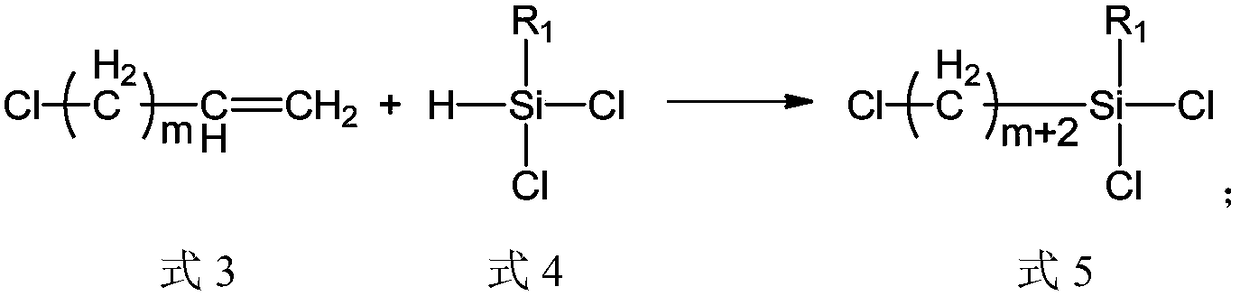

[0050] 1) add 4mol formula 4 compound and 0.05 μ mol catalyst A (carbon supported platinum) in the there-necked flask that thermometer, fractionating column are equipped with, drop into formula 3 compound (3mol) from the constant pressure funnel on the condenser, drop speed control Keep the temperature of the liquid in the flask at about 85°C, complete the dropwise addition for about 7 hours, and then reflux until there ar...

Embodiment 2

[0057] Silicon amine-based drilling fluid, composed of the following components in mass percentage: sodium bentonite 4%, sodium carboxymethylcellulose (CMC) 0.2%, hydrolyzed polyacrylamide potassium salt (KPAM) 0.3%, organic silicon potassium humate OSAM-K 2%, emulsified asphalt SFT 3%, aminosilanol inhibitor 1%, NaOH 0.2%, BaSO 4 20%, and the balance is water; wherein, the structural formula of the aminosilanol inhibitor is shown in formula 8, where R 1 is hydrogen, m takes 1, R 2 Take 1 for n.

[0058] The preparation steps of aminosilanol inhibitor are:

[0059] 1) add 3.2mol formula 4 compound and 0.05 μ mol catalyst A (carbon supported platinum) in the there-necked flask that thermometer, fractionating column are housed, drop into formula 3 compound (4mol) from the constant pressure funnel on the condenser, drop rate Control the temperature of the liquid in the flask at about 85°C, complete the dropwise addition for about 7 hours, and then reflux until there are almost...

Embodiment 3

[0066] Silicon amine-based drilling fluid, composed of the following components in mass percentage: sodium bentonite 4%, sodium carboxymethylcellulose (CMC) 0.2%, hydrolyzed polyacrylamide potassium salt (KPAM) 0.3%, organic silicon potassium humate OSAM-K 2%, emulsified asphalt SFT 2%, aminosilanol inhibitor 1%, NaOH 0.2%, BaSO 4 20%, and the balance is water; wherein, the structural formula of the aminosilanol inhibitor is shown in formula 8, where R 1 is hydrogen, m takes 2, R 2 Take 2 for n.

[0067] The preparation steps of aminosilanol inhibitor are:

[0068] 1) Add 6mol formula 4 compound and 0.1 μ mol catalyst A (carbon-supported platinum) in the there-necked flask equipped with thermometer and fractionating column, drop into formula 3 compound (5mol) from the constant pressure funnel on the condenser, the rate of addition is controlled Keep the temperature of the liquid in the flask at about 85°C, complete the dropwise addition for about 7 hours, and then reflux un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com