A kind of genuine stone paint additive and preparation method thereof

An additive and technology of real stone paint, applied in the direction of coating, etc., can solve the problems of easy blooming, poor acid and alkali resistance, and poor water resistance of real stone paint, so as to improve stability and fluidity, improve construction performance, and improve adhesion degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

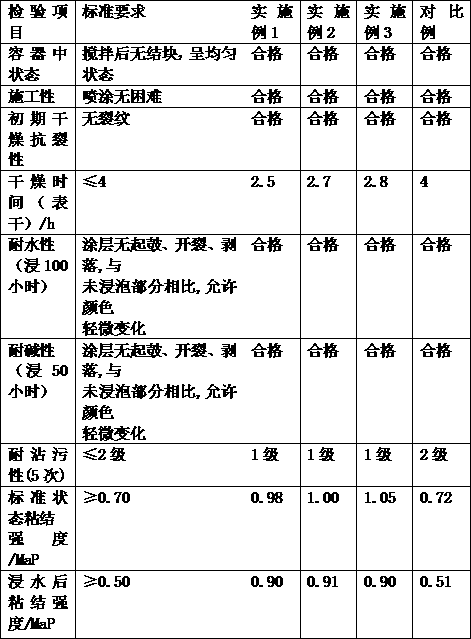

Examples

Embodiment 1

[0018] A real stone paint additive, made of the following components by weight: 10 parts of 2-aminoethyl-2,3-dihydroxypropyl-hydroxyphosphate, 17 parts of methyl fatty acid chloride, 8 parts of basic chromic acid Zinc, 1 part of cinchonaside, 6 parts of polyamine inhibitor CFY-01, 11 parts of sodium polydithiodipropane sulfonate, 20 parts of ethylene-acrylate copolymer, 0.2 parts of sodium oxalate, 50 parts of water.

[0019] Specifically, cinchonaside is a glycoside compound extracted from the bark of cinchona tree.

[0020] Specifically, the preparation method of described real stone paint additive comprises the following steps:

[0021] (1) Add sodium oxalate and cinchonaside into water, heat the water to 45°C, and stir for 10 minutes;

[0022] (2) Heat the mixture obtained in step (1) to 65°C, keep stirring, and add 2-aminoethyl-2,3-dihydroxypropyl-hydroxy phosphate and methyl fatty acid chloride to it, and stir for 12 minutes;

[0023] (3) Cool the mixture to 23°C, and ...

Embodiment 2

[0027] A real stone paint additive, made of the following components by weight: 12 parts of 2-aminoethyl-2,3-dihydroxypropyl-hydroxyphosphate, 18 parts of methyl fatty acid chloride, 9 parts of basic chromic acid Zinc, 2 parts of cinchonaside, 7 parts of polyamine inhibitor CFY-01, 11 parts of sodium polydithiodipropane sulfonate, 22 parts of ethylene-acrylate copolymer, 0.4 parts of sodium oxalate, 55 parts of water.

[0028] Specifically, cinchonaside is a glycoside compound extracted from the bark of cinchona tree.

[0029] Specifically, the preparation method of described real stone paint additive comprises the following steps:

[0030] (1) Add sodium oxalate and cinchonaside into water, heat the water to 47°C, and stir for 12 minutes;

[0031] (2) Heat the mixture obtained in step (1) to 67°C, keep stirring, and add 2-aminoethyl-2,3-dihydroxypropyl-hydroxy phosphate and methyl fatty acid chloride to it, and stir for 14 minutes;

[0032] (3) Cool the mixture to 24°C, and...

Embodiment 3

[0036] A real stone paint additive, made of the following components by weight: 15 parts of 2-aminoethyl-2,3-dihydroxypropyl-hydroxy phosphate, 19 parts of methyl fatty acid chloride, 10 parts of basic chromic acid Zinc, 3 parts of cinchonaside, 8 parts of polyamine inhibitor CFY-01, 12 parts of sodium polydithiodipropane sulfonate, 23 parts of ethylene-acrylate copolymer, 0.6 part of sodium oxalate, 60 parts of water.

[0037] Specifically, cinchonaside is a glycoside compound extracted from the bark of cinchona tree.

[0038] Specifically, the preparation method of described real stone paint additive comprises the following steps:

[0039] (1) Add sodium oxalate and cinchonaside into water, heat the water to 50°C, and stir for 15 minutes;

[0040] (2) Heat the mixture obtained in step (1) to 70°C, keep stirring, and add 2-aminoethyl-2,3-dihydroxypropyl-hydroxy phosphate and methyl fatty acid chloride to it, and stir for 15 minutes;

[0041] (3) Cool the mixture to 25°C, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com