Extreme pressure antifriction type drilling fluid and production method thereof

A drilling fluid and extreme pressure technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of short drilling fluid lubrication time, stuck drill, supporting pressure, etc. The effect of strong blocking ability and high reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

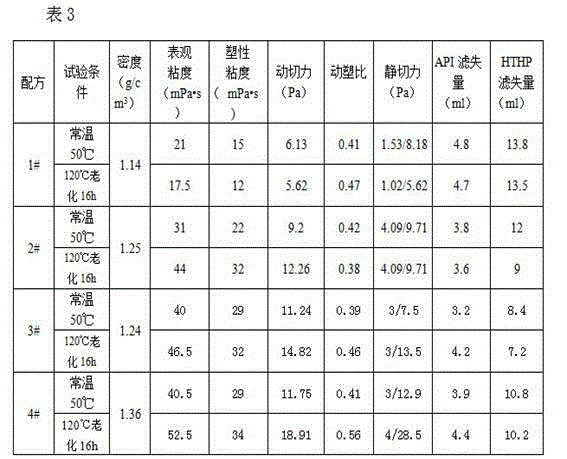

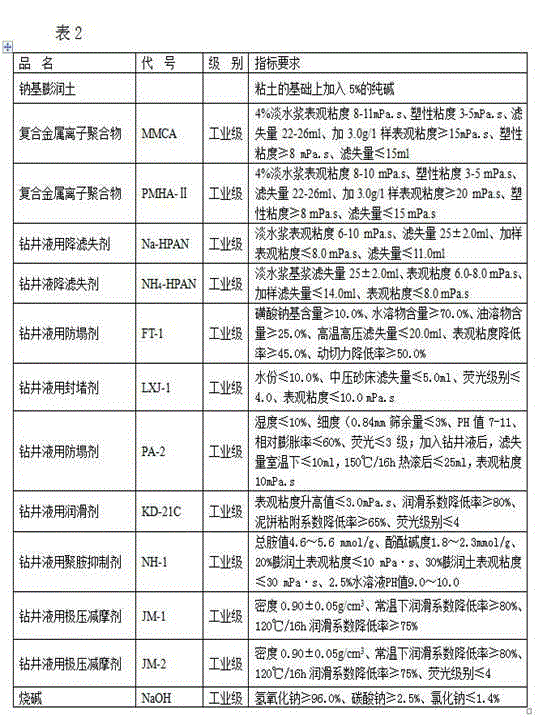

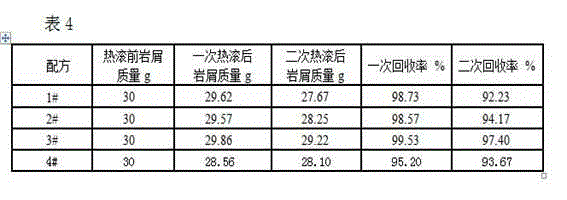

Embodiment 1

[0053] First mix 1000g of water with 50g of sodium bentonite, stir for 40 minutes at a stirring speed of 3000rpm, then stir for 30 minutes at a stirring speed of 8000rpm, and maintain at room temperature for 24 hours; stir the cured mixture at 4000rpm At high speed, first add 2g coating agent PMHA-II and 10g fluid loss reducer NH for drilling fluid 4 -HPAN, then add 10g of anti-slump agent PA-2 for drilling fluid, 1g of polyamine inhibitor NH-1 for drilling fluid, 5g of extreme pressure friction reducer JM-2 for drilling fluid, stir and mix evenly, and then add caustic soda Adjust the PH value of the above mixture to 8-9; finally add the weighting agent limestone powder for drilling fluid to the above mixture, stir evenly to make the density of the drilling fluid 1.14 g / cm 3 , that is, the extreme pressure anti-friction drilling fluid is obtained, which is recorded as 1# drilling fluid.

Embodiment 2

[0055] First mix 1000g of water with 60g of sodium bentonite, stir at a stirring speed of 4000rpm for 60 minutes, then stir at a stirring speed of 8000rpm for 40 minutes, and place it at room temperature for 30 hours; stir the cured mixture at 4000rpm At high speed, first add 5g of coating agent MMCA and 20g of drilling fluid fluid loss reducer Na-HPAN, then add 20g of drilling fluid anti-slump agent FT-1, 30g of drilling fluid lubricant KD-21C, 15g of drilling fluid Use plugging agent LXJ-1, 2g of polyamine inhibitor NH-1 for drilling fluid, 15g of extreme pressure friction reducer JM-2 for drilling fluid, stir and mix evenly, and then use caustic soda to bring the pH value of the above mixture to 8~ 9; Finally, add the weighting agent limestone powder for drilling fluid to the above mixture, stir evenly to make the density of drilling fluid 1.25 g / cm 3 , that is, the extreme pressure anti-friction drilling fluid is obtained, which is recorded as 2# drilling fluid.

Embodiment 3

[0057]First mix 1000g of water with 60g of sodium bentonite, stir at a stirring speed of 4000rpm for 60 minutes, then stir at a stirring speed of 8000rpm for 40 minutes, and place it at room temperature for curing for 30 hours; stir the cured mixture at 4000rpm At high speed, first add 7g coating agent PMHA-II and 30g drilling fluid fluid loss reducer Na-HPAN, then add 40g drilling fluid anti-slump agent FT-1, 50g drilling fluid lubricant KD-21C, 15g Drilling fluid plugging agent LXJ-1, 5g of drilling fluid polyamine inhibitor NH-1, 20g of drilling fluid extreme pressure friction reducer JM-1, after mixing evenly, use caustic soda to bring the pH value of the above mixture to 8~9; Finally, add limestone powder, a weighting agent for drilling fluid, to the above mixture, and stir evenly to make the density of drilling fluid 1.24 g / cm 3 , that is, the extreme pressure anti-friction drilling fluid is obtained, which is recorded as 3# drilling fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com